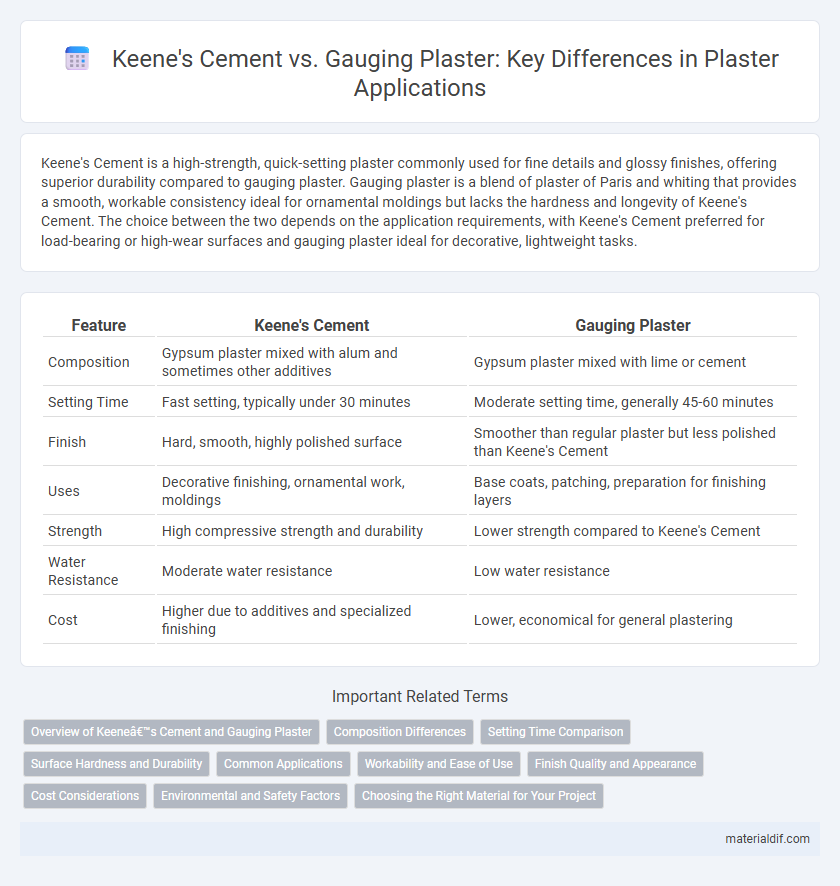

Keene's Cement is a high-strength, quick-setting plaster commonly used for fine details and glossy finishes, offering superior durability compared to gauging plaster. Gauging plaster is a blend of plaster of Paris and whiting that provides a smooth, workable consistency ideal for ornamental moldings but lacks the hardness and longevity of Keene's Cement. The choice between the two depends on the application requirements, with Keene's Cement preferred for load-bearing or high-wear surfaces and gauging plaster ideal for decorative, lightweight tasks.

Table of Comparison

| Feature | Keene's Cement | Gauging Plaster |

|---|---|---|

| Composition | Gypsum plaster mixed with alum and sometimes other additives | Gypsum plaster mixed with lime or cement |

| Setting Time | Fast setting, typically under 30 minutes | Moderate setting time, generally 45-60 minutes |

| Finish | Hard, smooth, highly polished surface | Smoother than regular plaster but less polished than Keene's Cement |

| Uses | Decorative finishing, ornamental work, moldings | Base coats, patching, preparation for finishing layers |

| Strength | High compressive strength and durability | Lower strength compared to Keene's Cement |

| Water Resistance | Moderate water resistance | Low water resistance |

| Cost | Higher due to additives and specialized finishing | Lower, economical for general plastering |

Overview of Keene’s Cement and Gauging Plaster

Keene's Cement is a high-quality, fine finishing plaster known for its smooth, hard surface and durability, often used in decorative molding and detailed plasterwork. Gauging plaster is a blend of plaster of Paris and whiting or lime, designed to improve workability, setting time, and surface finish, making it suitable for fine plaster applications. Both materials offer distinct benefits in finishing and decorative contexts, with Keene's Cement prized for its strength and smoothness, while gauging plaster provides ease of application and a refined appearance.

Composition Differences

Keene's Cement is primarily composed of calcined gypsum mixed with alum and other additives to enhance hardness and smoothness, making it ideal for fine finishing work. Gauging Plaster consists largely of plaster of Paris blended with a small amount of cement or lime, which improves its strength and reduces cracking but results in a rougher texture. The distinct compositional differences influence their applications, with Keene's Cement favored for detailed, polished surfaces and Gauging Plaster used for more durable base coats.

Setting Time Comparison

Keene's Cement sets significantly faster, typically within 20 to 30 minutes, making it ideal for quick repairs and detailed molding work. Gauging Plaster, which consists of plaster mixed with a small amount of cement, generally has a longer setting time of about 45 minutes to an hour, allowing more working time for leveling and smooth finishes. The faster setting of Keene's Cement provides a harder, more durable surface, while Gauging Plaster balances workability with moderate hardness.

Surface Hardness and Durability

Keene's Cement offers superior surface hardness and enhanced durability compared to Gauging Plaster, making it ideal for applications requiring a hard, wear-resistant finish. Its fine composition ensures a denser, more resilient surface that withstands abrasion better than the softer, more porous Gauging Plaster. Projects demanding long-lasting strength and robustness benefit significantly from Keene's Cement's advanced formulation.

Common Applications

Keene's Cement is commonly used for ornamental plasterwork, decorative molding, and restoration projects due to its smooth finish and high strength. Gauging Plaster, a mix of plaster and cement, is preferred for creating a harder finish on walls and ceilings, especially in areas prone to moisture. Both materials serve different roles in construction and renovation, with Keene's Cement favored for fine detailing and Gauging Plaster for durable, functional surfaces.

Workability and Ease of Use

Keene's Cement offers superior workability with a smoother, creamier consistency that makes it easier to apply and shape for fine detail work. Gauging plaster, mixed with lime and water, tends to be stiffer and requires more effort to manipulate, which may slow down intricate applications. The ease of use of Keene's Cement often results in faster project completion and a more refined finish compared to traditional gauging plaster.

Finish Quality and Appearance

Keene's Cement offers a smooth, hard finish ideal for fine ornamental work, delivering a highly durable and polished surface that enhances aesthetic appeal. Gauging Plaster, typically a mix of plaster and cement, provides greater strength but often results in a coarser texture and less refined appearance. For projects requiring superior finish quality and visual elegance, Keene's Cement is preferred due to its fine grain and superior setting properties.

Cost Considerations

Keene's Cement generally costs more than Gauging Plaster due to its enhanced durability and finer finish, making it a preferred choice for high-quality decorative work. Gauging Plaster, being a mixture of plaster and additives designed to retard setting time, is typically more affordable but may require more frequent maintenance. Cost considerations should balance the initial material price with the expected longevity and specific application requirements.

Environmental and Safety Factors

Keene's Cement is known for its superior durability but contains higher levels of silica dust, posing respiratory hazards that require strict protective measures during use. Gauging Plaster generally offers lower dust emissions and includes additives that reduce the risk of skin irritation, making it a safer choice for indoor applications with minimal ventilation. Both materials demand proper handling protocols, though Gauging Plaster aligns better with environmentally conscious projects due to its reduced airborne particulates and less intensive manufacturing process.

Choosing the Right Material for Your Project

Keene's cement offers a harder, more durable finish ideal for fine plasterwork requiring a smooth, resilient surface, while gauging plaster combines plaster with a filler like whiting to provide a quicker-setting, more workable mix suited for patching and smaller decorative details. Selecting Keene's cement ensures longevity and strength for high-traffic or structural applications, whereas gauging plaster is preferred for ease of use and flexibility in molding intricate designs. Understanding the specific demands of your project--durability versus workability--guides the choice between these two materials to achieve optimal results.

Keene’s Cement vs Gauging Plaster Infographic

materialdif.com

materialdif.com