A skim coat is a thin, smooth layer of plaster applied to walls for a polished finish, while a brown coat is a thicker, base layer that provides structural strength and a level surface. The brown coat serves as the foundational layer, allowing for better adhesion of the skim coat. Choosing the right sequence ensures durability and an even, flawless texture in plastering projects.

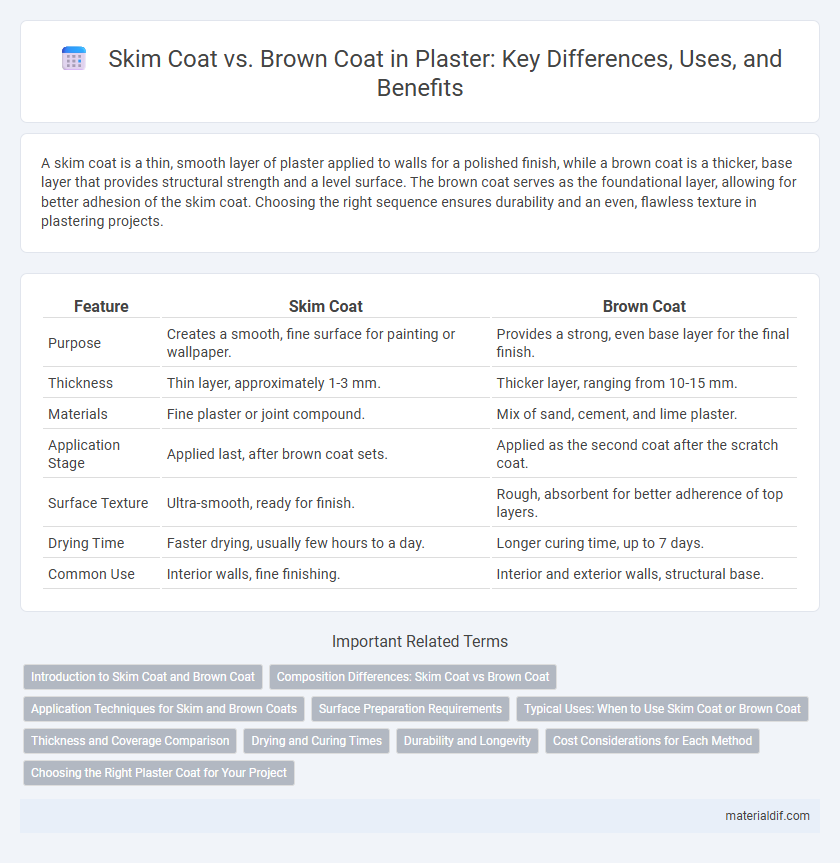

Table of Comparison

| Feature | Skim Coat | Brown Coat |

|---|---|---|

| Purpose | Creates a smooth, fine surface for painting or wallpaper. | Provides a strong, even base layer for the final finish. |

| Thickness | Thin layer, approximately 1-3 mm. | Thicker layer, ranging from 10-15 mm. |

| Materials | Fine plaster or joint compound. | Mix of sand, cement, and lime plaster. |

| Application Stage | Applied last, after brown coat sets. | Applied as the second coat after the scratch coat. |

| Surface Texture | Ultra-smooth, ready for finish. | Rough, absorbent for better adherence of top layers. |

| Drying Time | Faster drying, usually few hours to a day. | Longer curing time, up to 7 days. |

| Common Use | Interior walls, fine finishing. | Interior and exterior walls, structural base. |

Introduction to Skim Coat and Brown Coat

Skim coat is a thin plaster layer applied to walls for a smooth, even finish, often enhancing surface aesthetics and preparing walls for painting or wallpaper. Brown coat is a thicker, stronger layer applied beneath the skim coat, serving as the primary base that ensures durability and proper adhesion of the final surface. Understanding the roles of skim coat and brown coat is crucial for achieving both structural strength and a flawless wall appearance.

Composition Differences: Skim Coat vs Brown Coat

Skim coat typically consists of a thin layer of joint compound or plaster with fine aggregates and additives designed for smooth finishing and surface refinement. Brown coat contains a mixture of sand, cement, lime, and water, providing a thicker, sturdier base layer that ensures durability and adhesion for subsequent plaster applications. The composition variations directly impact their respective functions, with skim coat optimized for surface smoothness and brown coat for structural support.

Application Techniques for Skim and Brown Coats

Skim coat application involves spreading a thin, smooth layer of plaster using a trowel to achieve a polished, even surface ideal for final finishing, while brown coat application requires a thicker, rougher layer applied with a hawk and trowel to provide a strong, level base for subsequent layers. Skim coats demand precise, rapid strokes to prevent cracking and ensure uniformity, whereas brown coats involve combing and keying techniques to enhance adhesion and structural integrity. Proper timing between coats and moisture control are critical to both methods to optimize bonding and durability in plaster finishes.

Surface Preparation Requirements

Skim coat requires a smooth, clean, and dust-free surface to ensure proper adhesion and achieve a fine finish, often applied over existing plaster or drywall to cover minor imperfections. Brown coat demands a rough, keyed surface typically provided by the scratch coat, allowing the plaster to bond firmly and build up wall thickness for structural strength. Proper surface preparation for each coat is essential; skim coat surfaces must be free from loose particles, while brown coat surfaces need adequate texture to secure the plaster layer.

Typical Uses: When to Use Skim Coat or Brown Coat

Skim coat is typically used for creating a smooth, fine finish over existing plaster or drywall surfaces, ideal for repairing imperfections or preparing walls for painting. Brown coat is applied as a thicker base layer in plastering systems to provide structural strength and a level surface before the skim coat is added. In construction and renovation, use the brown coat for initial wall buildup and the skim coat for final surface refinement.

Thickness and Coverage Comparison

A skim coat typically has a thickness of about 1 to 3 millimeters, providing a smooth, fine finish ideal for surface imperfections and final aesthetics, whereas a brown coat is thicker, usually ranging from 12 to 25 millimeters, forming the structural base for subsequent plaster layers. Coverage of a skim coat is broader and thinner, allowing it to spread evenly across walls, while a brown coat requires more material due to its substantial thickness designed to level and strengthen surfaces. The skim coat's thin application focuses on detail refinement, contrasting with the brown coat's function as a durable, foundational layer.

Drying and Curing Times

Skim coat typically dries faster than brown coat, with drying times around 24 to 48 hours depending on environmental conditions, while brown coat requires 7 to 14 days for proper curing to achieve optimal strength and adhesion. Skim coat's thin layer facilitates rapid moisture evaporation, making it suitable for final finishing, whereas the thicker brown coat demands extended curing to prevent shrinkage and cracking. Proper curing of the brown coat is essential for durability and acts as a solid base for the subsequent skim coat application.

Durability and Longevity

The brown coat in plastering provides a thicker, more durable base layer, essential for structural strength and longevity, while the skim coat offers a thin, smooth finish primarily for aesthetic purposes. Brown coats typically enhance the plaster's resistance to cracking and environmental wear, ensuring a longer lifespan in both interior and exterior applications. Skim coats do not contribute significantly to durability but are crucial for achieving a flawless surface before painting or wallpapering.

Cost Considerations for Each Method

Skim coat application generally incurs higher labor costs due to its requirement for a smooth, fine finish and meticulous skill, making it more expensive than the brown coat, which serves as a rough, base layer and is less labor-intensive. Materials for skim coats often include finer plasters like gypsum or cement-based mixtures, which can increase overall expenses compared to the brown coat's basic cement or lime plaster. Choosing between skim coat and brown coat methods depends on budget constraints and the desired surface finish quality.

Choosing the Right Plaster Coat for Your Project

Skim coat and brown coat serve distinct purposes in plastering, with the brown coat offering a thicker, more durable base layer essential for structural integrity and moisture resistance. The skim coat provides a smooth, fine finish ideal for aesthetic enhancement and preparation for painting or wallpaper. Selecting the appropriate plaster coat depends on the project's stage and desired surface quality, ensuring long-lasting results and optimal finish.

Skim coat vs Brown coat Infographic

materialdif.com

materialdif.com