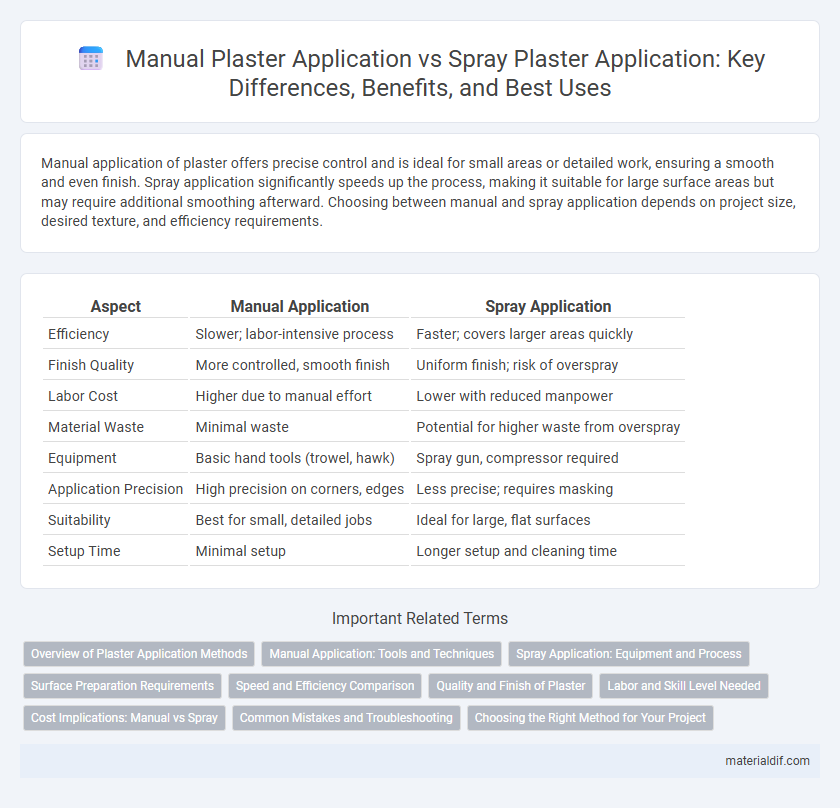

Manual application of plaster offers precise control and is ideal for small areas or detailed work, ensuring a smooth and even finish. Spray application significantly speeds up the process, making it suitable for large surface areas but may require additional smoothing afterward. Choosing between manual and spray application depends on project size, desired texture, and efficiency requirements.

Table of Comparison

| Aspect | Manual Application | Spray Application |

|---|---|---|

| Efficiency | Slower; labor-intensive process | Faster; covers larger areas quickly |

| Finish Quality | More controlled, smooth finish | Uniform finish; risk of overspray |

| Labor Cost | Higher due to manual effort | Lower with reduced manpower |

| Material Waste | Minimal waste | Potential for higher waste from overspray |

| Equipment | Basic hand tools (trowel, hawk) | Spray gun, compressor required |

| Application Precision | High precision on corners, edges | Less precise; requires masking |

| Suitability | Best for small, detailed jobs | Ideal for large, flat surfaces |

| Setup Time | Minimal setup | Longer setup and cleaning time |

Overview of Plaster Application Methods

Manual plaster application involves skilled craftsmen using trowels to spread and smooth plaster in multiple layers, allowing precise control over texture and thickness. Spray application employs pneumatic or mechanical sprayers, enabling faster coverage and uniformity on large surfaces, often preferred in commercial projects. Both methods require proper surface preparation and curing times, but spray application significantly reduces labor time while manual application offers greater customization for intricate finishes.

Manual Application: Tools and Techniques

Manual plaster application relies on essential tools such as trowels, hawk boards, and plastering floats to ensure smooth and even surfaces. Skilled artisans use techniques including layering, smoothing, and feathering to control plaster thickness and texture, enhancing wall durability and finish quality. This hands-on approach allows precise adjustments and meticulous detailing, ideal for intricate architectural features and small-scale repairs.

Spray Application: Equipment and Process

Spray application of plaster utilizes specialized equipment such as mechanical spray pumps and air compressors to efficiently deliver a consistent mixture onto surfaces. This process ensures faster coverage, reduces labor intensity, and achieves a smoother, more uniform finish compared to manual application. Proper calibration of spray pressure and nozzle size is essential to optimize material flow and minimize waste during application.

Surface Preparation Requirements

Manual plaster application demands meticulous surface preparation, including thorough cleaning, dampening, and roughening to ensure strong adhesion and prevent cracking. Spray application requires similar surface conditions but often benefits from enhanced surface profiling using bonding agents or primers to optimize plaster grip under high-velocity impact. Proper surface preparation directly influences plaster durability and finish quality in both application methods.

Speed and Efficiency Comparison

Manual plaster application requires skilled labor and is typically slower, making it less efficient for large-scale projects. Spray application significantly increases speed by covering surfaces uniformly and quickly, reducing labor time and costs. Spray technology also minimizes material waste, enhancing overall project efficiency and productivity.

Quality and Finish of Plaster

Manual application of plaster allows for precise control and attention to detail, resulting in a smoother and more consistent finish, especially on intricate surfaces. Spray application offers faster coverage but can sometimes lead to uneven thickness and issues with adhesion, potentially compromising the plaster's durability and overall quality. Selecting the appropriate method depends on the project scale and desired finish, with manual application often preferred for high-quality, finely finished surfaces.

Labor and Skill Level Needed

Manual plaster application demands higher labor intensity and skilled craftsmanship to ensure even coverage and smooth finishes, often requiring specialized training and experience. Spray application significantly reduces labor time and physical effort, but operators must be trained in handling equipment and adjusting spray techniques for consistent results. Choosing between methods depends on project scale, with spray application favoring large surfaces and manual application suitable for detailed or small-scale work.

Cost Implications: Manual vs Spray

Manual plaster application involves higher labor costs due to the time-intensive process, while spray application reduces labor expenses by accelerating coverage and minimizing material waste. Spray technology requires initial investment in specialized equipment, but offers long-term savings through improved efficiency and consistent application thickness. Choosing between manual and spray methods depends on project scale and budget constraints, with spray application favored for large-scale jobs requiring cost-effective labor management.

Common Mistakes and Troubleshooting

Common mistakes in manual plaster application include uneven thickness and improper mixing ratios, leading to cracking and poor adhesion. Spray application errors often involve incorrect nozzle pressure and inadequate surface preparation, causing overspray and rough texture. Troubleshooting requires adjusting mix consistency, maintaining steady application speed, and ensuring thorough surface cleaning to achieve optimal plaster finish.

Choosing the Right Method for Your Project

Manual application of plaster offers precision and control, ideal for detailed or small-scale projects requiring intricate finishes. Spray application accelerates coverage and ensures uniform thickness, making it suitable for large surfaces and commercial jobs. Assess project size, surface texture, and desired finish quality to select the most efficient plastering method.

Manual Application vs Spray Application Infographic

materialdif.com

materialdif.com