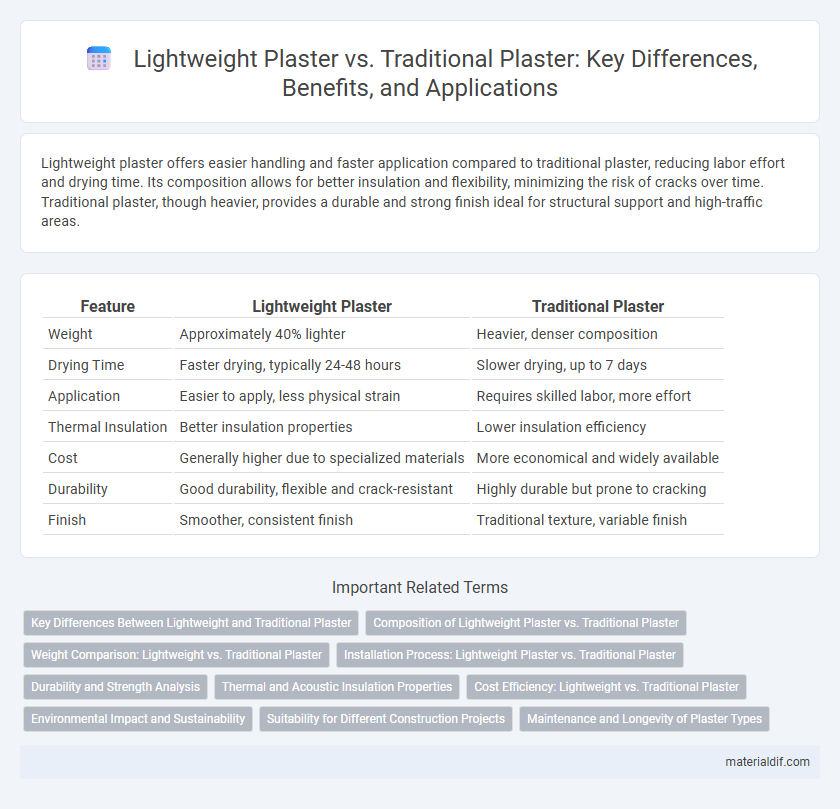

Lightweight plaster offers easier handling and faster application compared to traditional plaster, reducing labor effort and drying time. Its composition allows for better insulation and flexibility, minimizing the risk of cracks over time. Traditional plaster, though heavier, provides a durable and strong finish ideal for structural support and high-traffic areas.

Table of Comparison

| Feature | Lightweight Plaster | Traditional Plaster |

|---|---|---|

| Weight | Approximately 40% lighter | Heavier, denser composition |

| Drying Time | Faster drying, typically 24-48 hours | Slower drying, up to 7 days |

| Application | Easier to apply, less physical strain | Requires skilled labor, more effort |

| Thermal Insulation | Better insulation properties | Lower insulation efficiency |

| Cost | Generally higher due to specialized materials | More economical and widely available |

| Durability | Good durability, flexible and crack-resistant | Highly durable but prone to cracking |

| Finish | Smoother, consistent finish | Traditional texture, variable finish |

Key Differences Between Lightweight and Traditional Plaster

Lightweight plaster offers superior ease of application due to its reduced density, making it ideal for quicker renovations and reduced labor costs. Traditional plaster, with its higher density, provides greater durability and sound insulation, preferred for long-lasting, robust wall finishes. The key differences lie in weight, drying time, and thermal performance, with lightweight plaster drying faster and contributing to better energy efficiency compared to traditional options.

Composition of Lightweight Plaster vs. Traditional Plaster

Lightweight plaster typically consists of a mixture of gypsum, perlite, or vermiculite, which reduces its density and enhances thermal insulation properties, whereas traditional plaster is primarily composed of lime or cement combined with sand, making it denser and heavier. The inclusion of lightweight aggregates in lightweight plaster minimizes shrinkage and cracking compared to the rigid composition of traditional plaster. Lightweight plaster's formulation allows easier handling and faster drying times compared to the more robust and moisture-resistant composition of traditional plaster.

Weight Comparison: Lightweight vs. Traditional Plaster

Lightweight plaster typically weighs between 9 to 12 pounds per square foot, significantly reducing structural load compared to traditional plaster, which can weigh up to 15 pounds per square foot. This weight difference enhances ease of application and minimizes stress on building frameworks, making lightweight plaster ideal for renovation projects and older structures. Despite the reduced weight, lightweight plaster maintains comparable durability and finish quality to traditional plaster.

Installation Process: Lightweight Plaster vs. Traditional Plaster

Lightweight plaster offers a quicker installation process due to its ready-to-use formulation and reduced drying time compared to traditional plaster, which requires mixing and longer setting periods. The ease of application with lightweight plaster lowers labor costs and minimizes the risk of cracking during curing. Traditional plaster demands skilled craftsmanship to ensure a smooth finish, making it more time-consuming and labor-intensive.

Durability and Strength Analysis

Lightweight plaster offers improved flexibility and reduced cracking compared to traditional plaster, but traditional plaster generally demonstrates higher compressive strength and durability under heavy impact. The composition of traditional plaster, typically a mix of lime and sand, provides greater hardness and resistance to wear over time. Lightweight plaster, often made with foam or polymer additives, excels in ease of application and thermal insulation but may require reinforcement for high-stress environments.

Thermal and Acoustic Insulation Properties

Lightweight plaster offers superior thermal insulation due to its porous structure, reducing heat transfer compared to traditional plaster, which is denser and retains more heat. Acoustic insulation is enhanced in lightweight plaster, as its cellular composition effectively absorbs sound waves, minimizing noise transmission, whereas traditional plaster provides less sound absorption. These properties make lightweight plaster ideal for energy-efficient buildings and improved interior acoustics.

Cost Efficiency: Lightweight vs. Traditional Plaster

Lightweight plaster offers superior cost efficiency due to reduced material weight, lowering transportation and handling expenses compared to traditional plaster. Its faster drying time minimizes labor costs, enabling quicker project completion and less downtime. Traditional plaster, while often more durable, typically incurs higher overall costs because of extended application and curing periods.

Environmental Impact and Sustainability

Lightweight plaster significantly reduces environmental impact by utilizing recycled materials and requiring less energy during production compared to traditional plaster. Its lower raw material consumption and improved thermal insulation contribute to enhanced sustainability in building projects, reducing carbon emissions over the lifecycle of structures. Traditional plaster, made primarily from gypsum or cement, typically has a higher embodied energy and generates more waste, making lightweight alternatives preferable for eco-friendly construction.

Suitability for Different Construction Projects

Lightweight plaster offers superior insulation and quicker application, making it ideal for modern construction projects emphasizing energy efficiency and reduced structural load. Traditional plaster provides enhanced durability and soundproofing, suited for restoration work and buildings requiring increased fire resistance. Choosing between the two depends on project goals such as thermal performance, structural demands, and historical accuracy.

Maintenance and Longevity of Plaster Types

Lightweight plaster offers easier maintenance due to its enhanced flexibility and resistance to cracking, reducing the frequency of repairs compared to traditional plaster. Traditional plaster, while more durable in high-impact areas, tends to require periodic upkeep to address chipping and moisture-related damage over time. The longevity of lightweight plaster is often extended by its resistance to shrinkage and better adhesion qualities, making it a cost-effective choice for long-term maintenance.

Lightweight plaster vs Traditional plaster Infographic

materialdif.com

materialdif.com