Gypsum plaster sets quickly and provides a smooth, hard finish ideal for interior walls, while lime plaster offers greater breathability and flexibility, making it suitable for older buildings and exterior applications. Gypsum plaster has a lower environmental impact and is easier to apply but is less resistant to moisture compared to lime plaster. Lime plaster's natural antifungal properties and ability to absorb and release moisture help maintain healthier indoor air quality.

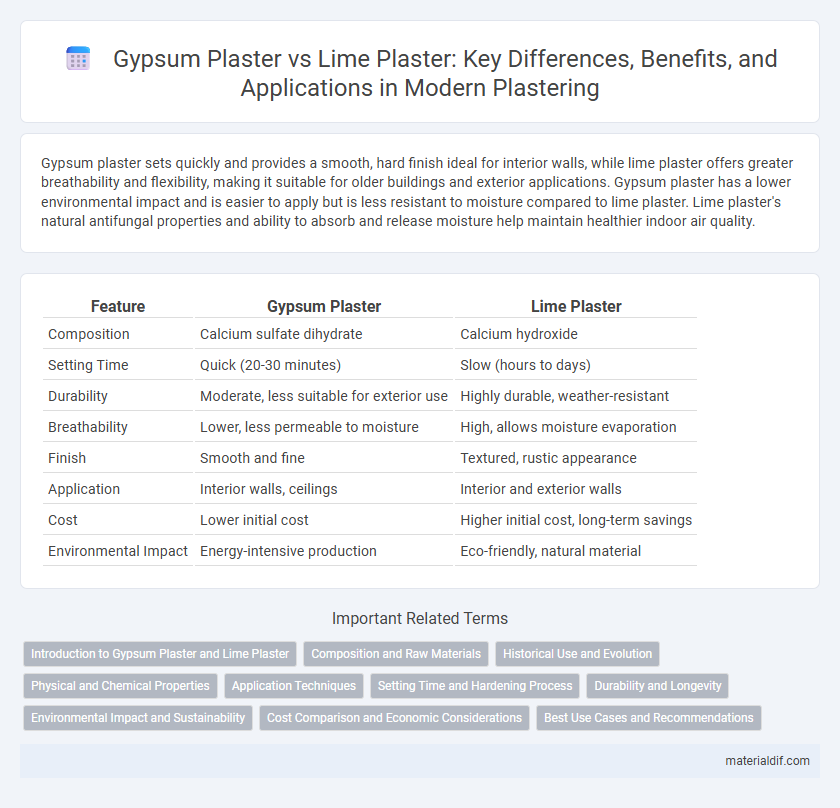

Table of Comparison

| Feature | Gypsum Plaster | Lime Plaster |

|---|---|---|

| Composition | Calcium sulfate dihydrate | Calcium hydroxide |

| Setting Time | Quick (20-30 minutes) | Slow (hours to days) |

| Durability | Moderate, less suitable for exterior use | Highly durable, weather-resistant |

| Breathability | Lower, less permeable to moisture | High, allows moisture evaporation |

| Finish | Smooth and fine | Textured, rustic appearance |

| Application | Interior walls, ceilings | Interior and exterior walls |

| Cost | Lower initial cost | Higher initial cost, long-term savings |

| Environmental Impact | Energy-intensive production | Eco-friendly, natural material |

Introduction to Gypsum Plaster and Lime Plaster

Gypsum plaster, composed primarily of calcium sulfate hemihydrate, is widely favored for its quick setting time, smooth finish, and superior fire resistance compared to traditional lime plaster. Lime plaster, made from calcium hydroxide, offers excellent breathability and flexibility, making it ideal for historic building restoration and moisture regulation. Both materials serve distinct architectural needs, with gypsum plaster excelling in modern construction and lime plaster preferred for its natural antimicrobial properties and environmental benefits.

Composition and Raw Materials

Gypsum plaster is primarily composed of calcium sulfate dihydrate, derived from natural gypsum rock or synthetic sources, offering quick setting and smooth finishes ideal for interior surfaces. Lime plaster consists chiefly of calcium hydroxide, obtained by burning limestone and slaking it with water, providing breathable and flexible coatings suitable for exterior and historic buildings. The distinct raw materials influence their chemical reactions, durability, and moisture management properties in construction applications.

Historical Use and Evolution

Gypsum plaster, rising to prominence in the 19th century, revolutionized construction with its quick setting time and smooth finish, making it a preferred material in modern architecture. Lime plaster, dating back thousands of years to ancient civilizations like the Egyptians and Romans, was valued for its breathability and durability, crucial in historical buildings. Over time, gypsum plaster's ease of application and fire resistance have largely replaced lime plaster in contemporary construction, though lime remains favored for restoration due to its compatibility with historic structures.

Physical and Chemical Properties

Gypsum plaster sets quickly due to its chemical composition of calcium sulfate hemihydrate, providing a smooth finish with minimal cracking, whereas lime plaster, primarily composed of calcium hydroxide, sets through carbonation, resulting in a slower curing process but greater flexibility and breathability. Gypsum plaster has low water resistance and is more prone to moisture damage, making it ideal for interior applications, while lime plaster's porous structure allows it to absorb and release moisture, enhancing durability in exterior environments. The hardness of gypsum plaster is higher upon setting, but lime plaster develops strength gradually and is less brittle, promoting longevity in traditional and restoration construction.

Application Techniques

Gypsum plaster is applied using a smooth trowel technique requiring a thinner layer, making it ideal for interior walls with rapid setting times and minimal shrinkage. Lime plaster demands multiple coats applied with a hawk and trowel, allowing for breathability and flexibility, which is essential for older or exterior structures. Both plasters require surface preparation, but gypsum plaster's faster drying time reduces overall project duration compared to the slower curing lime plaster.

Setting Time and Hardening Process

Gypsum plaster sets rapidly, typically within 20 to 30 minutes, enabling faster project completion, while lime plaster requires a longer setting time of several hours due to its carbonating hardening process. The hardening of gypsum plaster occurs through the crystallization of calcium sulfate dihydrate, providing quick strength but lower durability in moist conditions. Lime plaster hardens by reacting with carbon dioxide from the air, forming calcium carbonate that results in a slower but more flexible and breathable finish suitable for historic or moisture-prone buildings.

Durability and Longevity

Gypsum plaster offers faster setting times but generally has lower durability compared to lime plaster, which provides superior resistance to moisture and environmental wear. Lime plaster's chemical composition allows it to self-heal small cracks over time, significantly enhancing its longevity on exterior surfaces. For long-term structural protection and sustained aesthetic appeal, lime plaster remains the preferred choice in historic and moisture-prone applications.

Environmental Impact and Sustainability

Gypsum plaster has a lower carbon footprint compared to lime plaster due to its energy-efficient manufacturing process and rapid setting time, reducing overall energy consumption. Lime plaster promotes sustainability through its natural carbon sequestration properties, absorbing CO2 as it cures and enhancing indoor air quality. Both materials offer environmental benefits, but lime plaster's renewable origin and recyclability make it preferable for eco-friendly construction projects.

Cost Comparison and Economic Considerations

Gypsum plaster generally costs more upfront than lime plaster due to its synthetic processing but offers faster application and drying times, which can reduce labor expenses. Lime plaster is usually cheaper and made from natural materials, making it more cost-effective for large-scale projects despite slower curing times. Economic considerations also include maintenance; gypsum plaster requires less frequent repairs compared to lime plaster, potentially lowering long-term costs.

Best Use Cases and Recommendations

Gypsum plaster is ideal for interior walls and ceilings due to its fast setting time, smooth finish, and resistance to cracking, making it suitable for dry environments and modern construction. Lime plaster excels in exterior applications and historic restoration projects because of its breathability, flexibility, and ability to withstand moisture and weathering. For durability in wet or outdoor conditions, lime plaster is recommended, while gypsum plaster is best for quick, clean interior finishes.

Gypsum Plaster vs Lime Plaster Infographic

materialdif.com

materialdif.com