Casting plaster is a fine, fast-setting material primarily used for detailed molds and sculptures due to its smooth texture and quick hardening properties. Skim coat plaster, on the other hand, is designed for applying thin layers over walls or ceilings to create a uniform and smooth surface, often used to cover imperfections. Choosing between casting plaster and skim coat plaster depends on the project requirements, with casting plaster suited for artistic and decorative work, and skim coat plaster ideal for surface finishing and preparation before painting.

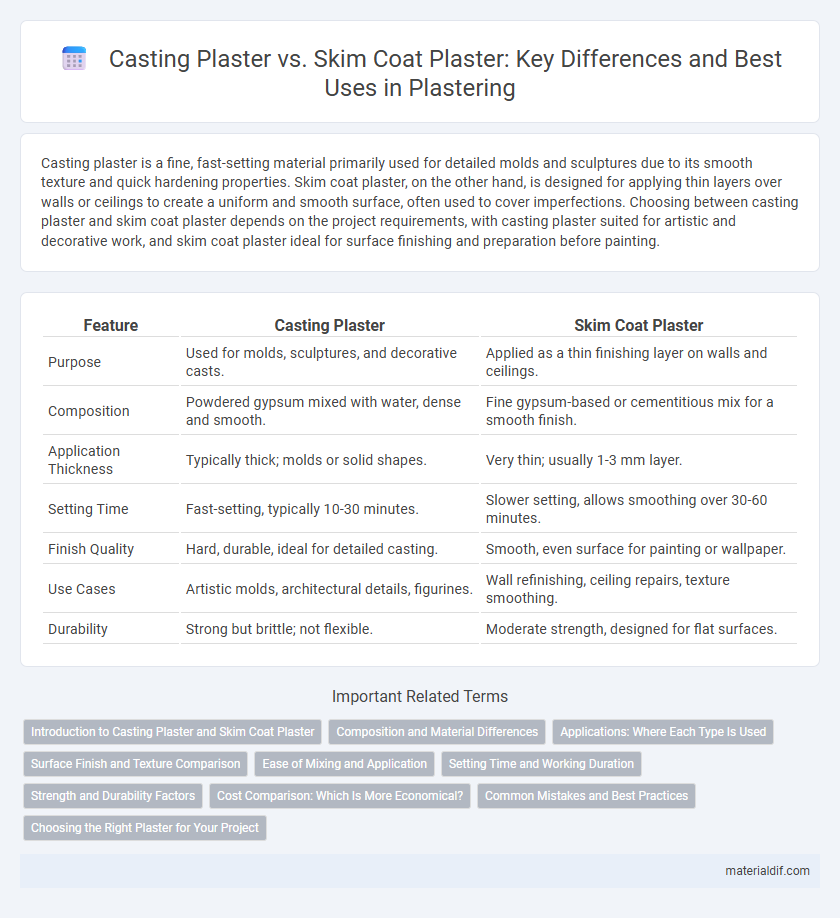

Table of Comparison

| Feature | Casting Plaster | Skim Coat Plaster |

|---|---|---|

| Purpose | Used for molds, sculptures, and decorative casts. | Applied as a thin finishing layer on walls and ceilings. |

| Composition | Powdered gypsum mixed with water, dense and smooth. | Fine gypsum-based or cementitious mix for a smooth finish. |

| Application Thickness | Typically thick; molds or solid shapes. | Very thin; usually 1-3 mm layer. |

| Setting Time | Fast-setting, typically 10-30 minutes. | Slower setting, allows smoothing over 30-60 minutes. |

| Finish Quality | Hard, durable, ideal for detailed casting. | Smooth, even surface for painting or wallpaper. |

| Use Cases | Artistic molds, architectural details, figurines. | Wall refinishing, ceiling repairs, texture smoothing. |

| Durability | Strong but brittle; not flexible. | Moderate strength, designed for flat surfaces. |

Introduction to Casting Plaster and Skim Coat Plaster

Casting plaster is a fine, white powder primarily used for creating detailed molds and sculptures due to its quick setting time and smooth finish. Skim coat plaster, formulated for wall and ceiling applications, provides a thin, even layer to smooth surfaces before painting or wallpapering. Each type of plaster offers distinct properties tailored to specific construction and artistic needs.

Composition and Material Differences

Casting plaster primarily contains fine calcined gypsum, making it denser and ideal for mold reproduction due to its smooth, hard finish. Skim coat plaster typically incorporates lime or cement additives, resulting in a lighter consistency tailored for wall finishing and surface leveling. These material differences influence drying time, strength, and application techniques in construction and artistic projects.

Applications: Where Each Type Is Used

Casting plaster is primarily used for creating detailed molds, sculptures, and ornamental pieces due to its fine texture and quick setting properties. Skim coat plaster is applied as a thin, smooth layer on walls and ceilings to achieve a flawless finish before painting or wallpapering. While casting plaster is ideal for ornamental and artistic applications, skim coat plaster excels in surface preparation for interior decoration.

Surface Finish and Texture Comparison

Casting plaster offers a smooth, dense surface ideal for detailed mold reproduction, delivering a hard and durable finish often used in sculptural and decorative applications. Skim coat plaster provides a thinner, more flexible layer designed to create a uniform, flat wall surface that effectively hides imperfections with a finer texture. The key difference lies in casting plaster's rigid, polished surface versus the skim coat plaster's matte, subtle texture optimized for smooth wall finishes.

Ease of Mixing and Application

Casting plaster offers a finer, smoother consistency that mixes easily with water, ensuring a lump-free blend ideal for detailed mold work. Skim coat plaster, designed for wall and ceiling finishes, requires careful water ratio adjustment to achieve a spreadable texture that adheres smoothly to surfaces. The simplicity of mixing casting plaster suits quick, precise applications, while skim coat plaster demands more skill to apply evenly across broader areas.

Setting Time and Working Duration

Casting plaster typically has a fast setting time of 5 to 15 minutes, allowing for quick mold-making and detailed reproduction, while its working duration is very short, requiring rapid application. Skim coat plaster, on the other hand, sets more slowly, usually within 30 to 60 minutes, providing an extended working time for smoothing and finishing wall surfaces. The longer setting time and working duration of skim coat plaster make it ideal for achieving a flat, even surface on interior walls and ceilings.

Strength and Durability Factors

Casting plaster offers lower strength and durability, making it ideal for decorative molds and sculptures rather than structural applications. Skim coat plaster, formulated with stronger binders and additives, provides enhanced adhesion and resistance to cracking, ensuring a more durable and long-lasting finish on walls and ceilings. The choice between casting plaster and skim coat plaster should consider the required mechanical performance and exposure conditions for optimal results.

Cost Comparison: Which Is More Economical?

Casting plaster generally costs more per bag but requires less material for small molds, making it economical for detailed, limited projects. Skim coat plaster is cheaper per unit and covers larger wall surfaces efficiently, reducing labor costs for broad applications. Choosing between them depends on project scale and precision needs, affecting overall cost-effectiveness.

Common Mistakes and Best Practices

Casting plaster often suffers from mistakes such as improper mixing ratios leading to weak casts, while skim coat plaster errors typically involve uneven application causing surface imperfections. Best practices include thoroughly measuring water-to-plaster ratios for casting and using consistent, thin layers with proper troweling techniques for skim coating. Ensuring timely application before drying and maintaining controlled environmental conditions are crucial for both types to achieve durable, smooth finishes.

Choosing the Right Plaster for Your Project

Casting plaster offers high strength and fast setting times, making it ideal for creating detailed molds and sculptures, while skim coat plaster provides a smooth, thin finishing layer suited for wall refinishing and repairs. Choosing the right plaster depends on project requirements: casting plaster excels in durability and shape retention, whereas skim coat plaster enhances surface texture and appearance. Evaluate the application area, desired finish, and drying time to determine whether casting plaster's rigidity or skim coat plaster's finesse best aligns with your project goals.

Casting Plaster vs Skim Coat Plaster Infographic

materialdif.com

materialdif.com