Conventional plaster requires skilled manual application, resulting in a textured finish that can vary depending on the artisan's expertise. Machine-applied plaster offers faster, more consistent coverage with a smoother finish, ideal for large-scale projects demanding uniformity. Choosing between the two depends on budget constraints, desired aesthetic, and project timeline.

Table of Comparison

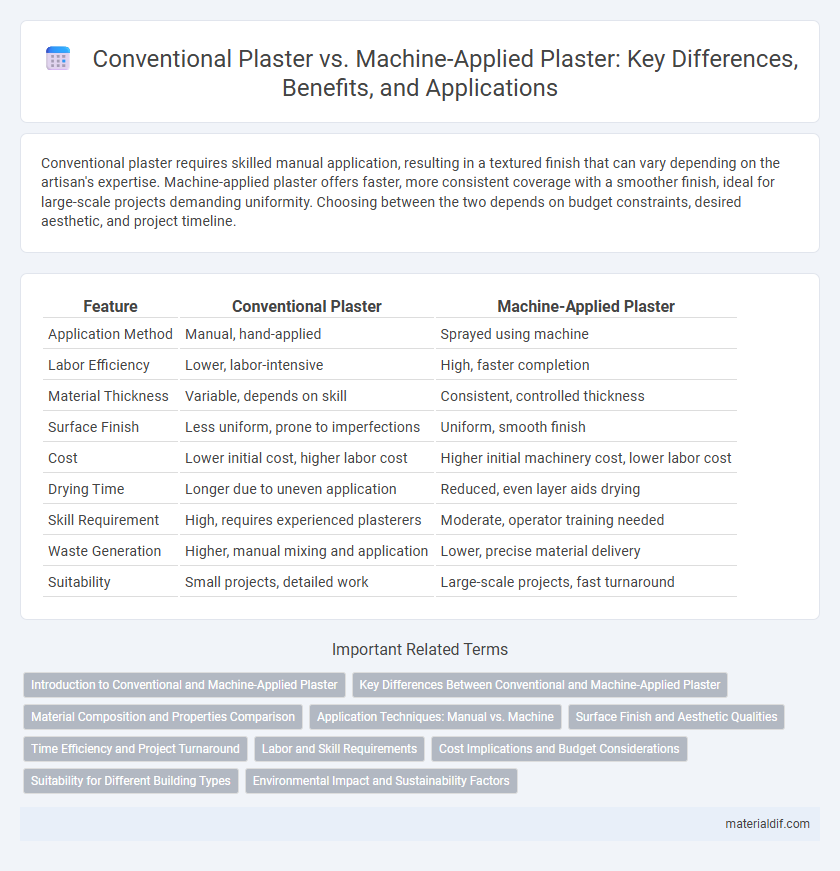

| Feature | Conventional Plaster | Machine-Applied Plaster |

|---|---|---|

| Application Method | Manual, hand-applied | Sprayed using machine |

| Labor Efficiency | Lower, labor-intensive | High, faster completion |

| Material Thickness | Variable, depends on skill | Consistent, controlled thickness |

| Surface Finish | Less uniform, prone to imperfections | Uniform, smooth finish |

| Cost | Lower initial cost, higher labor cost | Higher initial machinery cost, lower labor cost |

| Drying Time | Longer due to uneven application | Reduced, even layer aids drying |

| Skill Requirement | High, requires experienced plasterers | Moderate, operator training needed |

| Waste Generation | Higher, manual mixing and application | Lower, precise material delivery |

| Suitability | Small projects, detailed work | Large-scale projects, fast turnaround |

Introduction to Conventional and Machine-Applied Plaster

Conventional plaster involves manual application using trowels and hawks, relying heavily on skilled labor for smooth, even surfaces. Machine-applied plaster employs automated spraying equipment that enhances productivity and consistency, especially in large-scale projects. Both methods use gypsum or cement-based plaster, but machine application reduces labor intensity and speeds up construction timelines.

Key Differences Between Conventional and Machine-Applied Plaster

Conventional plaster involves manual application using trowels, resulting in variable thickness and longer drying times, whereas machine-applied plaster ensures consistent coating with greater speed and uniformity. Machine plastering utilizes spray technology that reduces labor costs and enhances surface finish quality compared to conventional hand-applied methods. Key differences include productivity rates, material wastage, and the level of skilled labor required, making machine-applied plaster more efficient for large-scale construction projects.

Material Composition and Properties Comparison

Conventional plaster typically consists of a blend of gypsum, lime, sand, and water, providing a fine finish with good workability and moderate setting times, whereas machine-applied plaster often incorporates additives and polymers to enhance adhesion, durability, and faster curing. The material composition of machine-applied plaster allows for more uniform application, improved mechanical strength, and greater resistance to cracking compared to traditional plaster mixes. Both types offer strong bonding properties, but machine-applied plaster demonstrates superior consistency and reduced labor intensity due to automated application methods.

Application Techniques: Manual vs. Machine

Conventional plaster relies on manual application techniques, where skilled workers apply the mix using trowels and hawks, allowing for precise control over texture and thickness but requiring significant labor and time. Machine-applied plaster uses spray equipment to deliver a consistent, uniform layer rapidly, reducing labor costs and improving efficiency on large-scale projects. The choice between manual and machine application impacts project duration, surface finish quality, and labor skill requirements.

Surface Finish and Aesthetic Qualities

Conventional plaster, applied manually, offers a textured and artisanal surface finish favored for traditional aesthetics and detailed customization. Machine-applied plaster ensures consistent thickness and smoother surfaces, achieving a uniform, modern look with reduced labor time. Surface finish quality varies as conventional plaster emphasizes craftsmanship, whereas machine application prioritizes efficiency and repeatability.

Time Efficiency and Project Turnaround

Conventional plaster application requires skilled labor and longer setting times, often extending project turnaround due to manual layering and curing processes. Machine-applied plaster significantly accelerates the workflow by ensuring uniform coverage and faster drying through mechanized spraying techniques. This enhanced time efficiency reduces labor costs and shortens overall construction schedules, making machine application ideal for large-scale projects.

Labor and Skill Requirements

Conventional plaster requires skilled labor with expertise in manual application techniques, making the process time-consuming and dependent on artisan craftsmanship. Machine-applied plaster reduces labor intensity by automating the application, allowing for faster completion with less manual expertise needed, significantly lowering labor costs. The choice impacts project timelines and quality, with machine application favoring efficiency and conventional methods ensuring precision through skilled workmanship.

Cost Implications and Budget Considerations

Conventional plaster involves higher labor costs due to manual application techniques, making it more expensive for large-scale projects. Machine-applied plaster reduces labor expenses and increases application speed, offering significant savings in both time and money. Budget considerations must weigh upfront equipment investment against long-term savings in operational costs and project timelines.

Suitability for Different Building Types

Conventional plaster suits intricate restoration projects and small-scale residential buildings, providing fine detail and control for uneven surfaces. Machine-applied plaster excels in commercial and large-scale construction due to faster application and consistent thickness, ideal for smooth walls and uniform finishes. Choice depends on project scale, surface complexity, and desired finish quality, with conventional methods favored for traditional aesthetics and machine application for efficiency.

Environmental Impact and Sustainability Factors

Conventional plaster typically involves manual application, leading to higher material waste and increased energy consumption due to longer drying times and inefficient resource use. Machine-applied plaster reduces waste by ensuring precise mixing and uniform application, lowering environmental impact through decreased material consumption and faster project completion. Sustainable plaster solutions favor machine application for improved resource efficiency and minimized carbon footprint in construction projects.

Conventional Plaster vs Machine-Applied Plaster Infographic

materialdif.com

materialdif.com