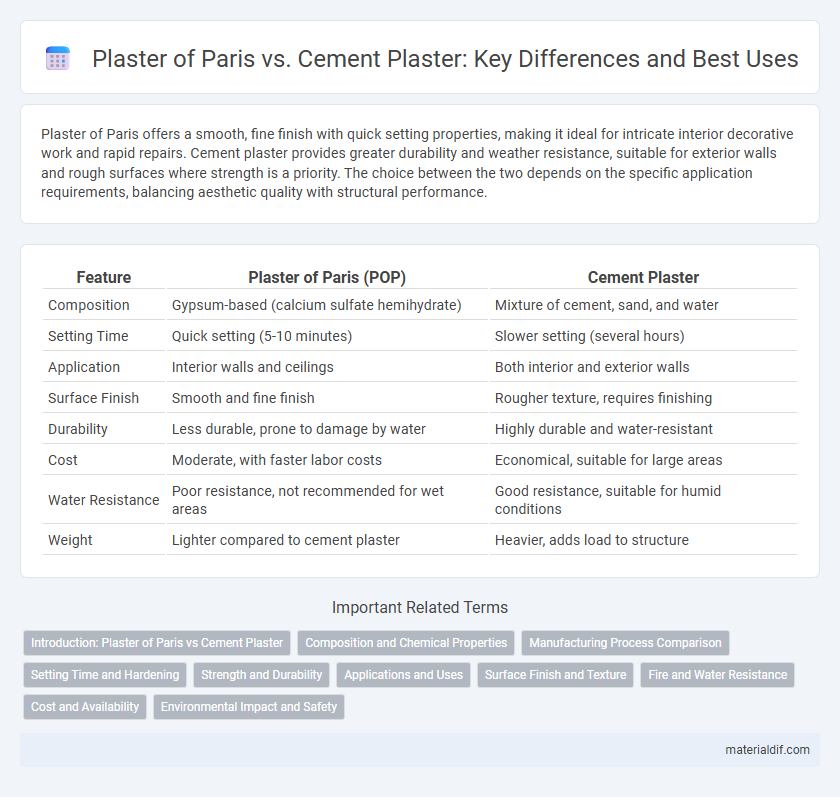

Plaster of Paris offers a smooth, fine finish with quick setting properties, making it ideal for intricate interior decorative work and rapid repairs. Cement plaster provides greater durability and weather resistance, suitable for exterior walls and rough surfaces where strength is a priority. The choice between the two depends on the specific application requirements, balancing aesthetic quality with structural performance.

Table of Comparison

| Feature | Plaster of Paris (POP) | Cement Plaster |

|---|---|---|

| Composition | Gypsum-based (calcium sulfate hemihydrate) | Mixture of cement, sand, and water |

| Setting Time | Quick setting (5-10 minutes) | Slower setting (several hours) |

| Application | Interior walls and ceilings | Both interior and exterior walls |

| Surface Finish | Smooth and fine finish | Rougher texture, requires finishing |

| Durability | Less durable, prone to damage by water | Highly durable and water-resistant |

| Cost | Moderate, with faster labor costs | Economical, suitable for large areas |

| Water Resistance | Poor resistance, not recommended for wet areas | Good resistance, suitable for humid conditions |

| Weight | Lighter compared to cement plaster | Heavier, adds load to structure |

Introduction: Plaster of Paris vs Cement Plaster

Plaster of Paris (POP) is a fast-setting material made from calcined gypsum, known for its smooth finish and ease of molding, commonly used for interior walls and decorative work. Cement plaster, composed of cement, sand, and water, offers greater durability and weather resistance, making it suitable for exterior surfaces and rough-textured finishes. POP sets quickly within minutes, while cement plaster requires curing over several days to achieve optimal strength and adherence.

Composition and Chemical Properties

Plaster of Paris is composed primarily of calcium sulfate hemihydrate (CaSO4*0.5H2O), which sets quickly due to its exothermic hydration reaction forming gypsum (CaSO4*2H2O). Cement plaster consists mainly of Portland cement, a mixture of clinker phases such as alite (C3S), belite (C2S), and calcium sulfate, which hardens through hydration reactions producing calcium silicate hydrate (C-S-H) gel and calcium hydroxide. The chemical properties of Plaster of Paris allow fast setting and smooth finishing but lower water resistance, while cement plaster offers higher durability and strength due to its hydraulic setting mechanism.

Manufacturing Process Comparison

Plaster of Paris is manufactured by heating natural gypsum to around 150degC, causing it to lose water and form a fine powder that rehydrates quickly when mixed with water. Cement plaster involves mixing Portland cement, sand, and water, relying on a hydration process that hardens and gains strength over time. The key difference lies in the rapid chemical setting of Plaster of Paris versus the slower curing of cement plaster, influencing application speed and surface finish quality.

Setting Time and Hardening

Plaster of Paris sets rapidly, typically within 10 to 20 minutes, allowing for quick application and smooth finishing in interior works. Cement plaster requires a longer setting time of about 24 to 48 hours, providing greater durability and strength after curing. Due to its longer hardening process, cement plaster is preferred for exterior surfaces exposed to weather conditions.

Strength and Durability

Plaster of Paris offers a smooth finish but has lower strength and durability compared to cement plaster, making it unsuitable for exterior surfaces. Cement plaster provides high compressive strength and resistance to weathering, ensuring long-lasting protection for walls and ceilings. Its robustness and moisture resistance make cement plaster ideal for structural applications requiring enhanced durability.

Applications and Uses

Plaster of Paris is primarily used for decorative applications such as moldings, sculptures, and interior wall finishes due to its quick setting properties and smooth texture. Cement plaster is favored for exterior surfaces and structural walls because of its durability, water resistance, and strong adhesive qualities. Both materials play vital roles in construction, with Plaster of Paris ideal for fine, detailed work and cement plaster suited for robust, weather-resistant surfaces.

Surface Finish and Texture

Plaster of Paris provides a smooth, fine-textured surface finish ideal for interior walls and intricate moldings, offering superior ease of application and rapid setting time. Cement plaster delivers a coarser, more durable finish suitable for exterior walls, resistant to weathering and mechanical wear. The selection between Plaster of Paris and cement plaster depends on desired surface texture, durability requirements, and environmental exposure.

Fire and Water Resistance

Plaster of Paris offers excellent fire resistance due to its non-combustible nature and ability to withstand high temperatures without cracking. Cement plaster provides superior water resistance, making it ideal for external walls and damp environments because of its impermeable and durable composition. Choosing between them depends on the specific requirements for fire safety or moisture protection in construction projects.

Cost and Availability

Plaster of Paris (POP) is generally more expensive than cement plaster due to its finer finish and quicker setting time, though it is widely available in urban areas. Cement plaster is more cost-effective and readily accessible, especially in rural and construction sites where bulk quantities are needed. The choice between POP and cement plaster often depends on budget constraints and the required application speed.

Environmental Impact and Safety

Plaster of Paris (POP) produces less dust and requires lower energy during curing compared to cement plaster, resulting in a reduced carbon footprint and fewer harmful emissions. Cement plaster involves the extraction and processing of raw materials like limestone, contributing significantly to environmental degradation and higher CO2 emissions. POP poses minimal health risks when properly handled, whereas cement plaster dust may cause respiratory issues and skin irritation due to its alkaline nature.

Plaster of Paris vs Cement plaster Infographic

materialdif.com

materialdif.com