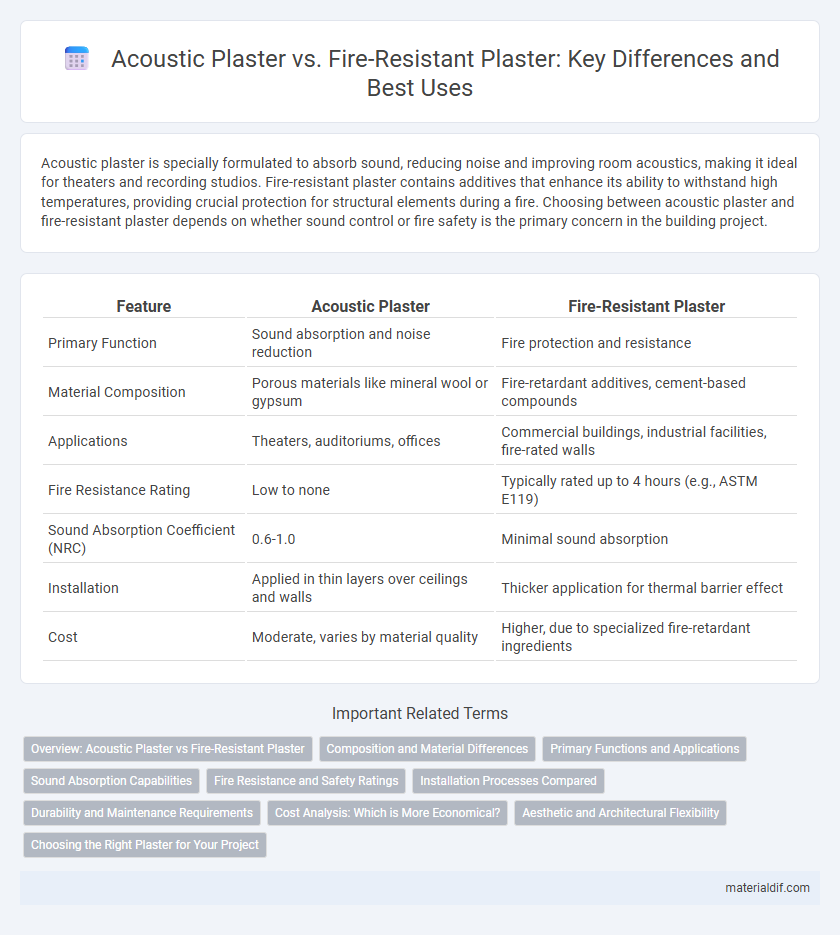

Acoustic plaster is specially formulated to absorb sound, reducing noise and improving room acoustics, making it ideal for theaters and recording studios. Fire-resistant plaster contains additives that enhance its ability to withstand high temperatures, providing crucial protection for structural elements during a fire. Choosing between acoustic plaster and fire-resistant plaster depends on whether sound control or fire safety is the primary concern in the building project.

Table of Comparison

| Feature | Acoustic Plaster | Fire-Resistant Plaster |

|---|---|---|

| Primary Function | Sound absorption and noise reduction | Fire protection and resistance |

| Material Composition | Porous materials like mineral wool or gypsum | Fire-retardant additives, cement-based compounds |

| Applications | Theaters, auditoriums, offices | Commercial buildings, industrial facilities, fire-rated walls |

| Fire Resistance Rating | Low to none | Typically rated up to 4 hours (e.g., ASTM E119) |

| Sound Absorption Coefficient (NRC) | 0.6-1.0 | Minimal sound absorption |

| Installation | Applied in thin layers over ceilings and walls | Thicker application for thermal barrier effect |

| Cost | Moderate, varies by material quality | Higher, due to specialized fire-retardant ingredients |

Overview: Acoustic Plaster vs Fire-Resistant Plaster

Acoustic plaster is engineered to absorb sound waves, enhancing room acoustics and reducing noise levels, making it ideal for theaters and recording studios. Fire-resistant plaster is formulated with materials like gypsum and additives to withstand high temperatures, providing critical fire protection in buildings. Both types serve distinct functional purposes: acoustic plaster prioritizes sound management, while fire-resistant plaster focuses on safety and structural integrity during fire incidents.

Composition and Material Differences

Acoustic plaster is composed of sound-absorbing materials such as mineral fibers, perforated panels, and gypsum-based compounds designed to improve room acoustics by reducing echo and noise levels. Fire-resistant plaster incorporates fire-retardant additives like vermiculite, silica, and fiberglass to enhance thermal protection and structural integrity under high temperatures. The primary material difference lies in acoustic plaster's porous structure for sound diffusion versus fire-resistant plaster's dense, heat-resistant composition for fire safety compliance.

Primary Functions and Applications

Acoustic plaster is designed to absorb sound and reduce noise levels, making it ideal for theaters, studios, and conference rooms where sound clarity is crucial. Fire-resistant plaster provides enhanced fire protection and is commonly used in commercial buildings, industrial facilities, and residential structures to slow fire spread and protect structural integrity. Both types serve distinct functions, with acoustic plaster focused on sound management and fire-resistant plaster on safety and compliance with fire codes.

Sound Absorption Capabilities

Acoustic plaster is specifically designed to enhance sound absorption, reducing reverberation and improving room acoustics by incorporating materials with high sound-absorbing properties. Fire-resistant plaster primarily focuses on providing thermal insulation and preventing fire spread, with limited effectiveness in sound absorption compared to acoustic plaster. When prioritizing sound absorption capabilities, acoustic plaster is the superior choice due to its engineered porous structure that dissipates sound waves efficiently.

Fire Resistance and Safety Ratings

Fire-resistant plaster is specifically formulated to withstand high temperatures, providing critical fire protection and meeting stringent safety ratings such as ASTM E119 and UL 263. Acoustic plaster, while offering excellent sound absorption and noise reduction capabilities, generally lacks the enhanced fire resistance properties necessary for compliance with fire safety codes. Prioritizing fire-resistant plaster in construction ensures improved occupant safety and compliance with building regulations focused on fire containment and prevention.

Installation Processes Compared

Acoustic plaster requires precise layering of noise-absorbing materials with careful attention to thickness and density to maximize sound dampening effects, often involving professional application for optimal results. Fire-resistant plaster installation demands strict adherence to safety standards, including the incorporation of fire retardants and multiple coats to meet regulatory fire rating requirements. Both installation processes prioritize surface preparation but differ significantly in material composition and curing times to achieve their respective performance properties.

Durability and Maintenance Requirements

Acoustic plaster offers excellent sound absorption properties but generally requires more frequent maintenance due to its softer surface prone to dents and stains. Fire-resistant plaster is engineered for high durability and can withstand extreme temperatures without compromising structural integrity, reducing the need for repairs in fire-prone environments. Both types demand specific care, but fire-resistant plaster's robust composition typically results in lower long-term maintenance costs.

Cost Analysis: Which is More Economical?

Acoustic plaster typically incurs higher upfront costs due to specialized sound-absorbing materials and installation techniques, making it less economical for budget-focused projects. Fire-resistant plaster, while potentially more expensive than standard plaster, often provides cost savings through insurance benefits and enhanced safety compliance. Evaluating long-term investment and functional priorities helps determine which plaster type offers better economic value.

Aesthetic and Architectural Flexibility

Acoustic plaster offers superior aesthetic versatility by providing a seamless, smooth surface that enhances architectural design without visible panels or perforations, making it ideal for modern interior applications. Fire-resistant plaster emphasizes safety while maintaining a clean finish, allowing architects to incorporate fire protection features without compromising visual appeal or structural design. Both types support diverse architectural flexibility, but acoustic plaster excels in creating sound-absorbing environments with minimalist design, whereas fire-resistant plaster prioritizes compliance with fire codes alongside customizable texture and color options.

Choosing the Right Plaster for Your Project

Acoustic plaster enhances sound absorption and noise reduction, making it ideal for theaters, auditoriums, and office spaces requiring superior acoustics. Fire-resistant plaster offers critical protection by delaying fire spread and maintaining structural integrity, essential for commercial buildings and safety-compliant projects. Selecting the right plaster depends on project priorities such as acoustic performance versus fire safety, ensuring optimal functionality and regulatory compliance.

Acoustic Plaster vs Fire-Resistant Plaster Infographic

materialdif.com

materialdif.com