Plaster of Paris (POP) offers a smooth finish and quick setting time, making it ideal for detailed molding and interior wall applications. Lime plaster, known for its breathability and durability, is preferred in historic restorations and exterior surfaces to prevent moisture buildup and enhance wall longevity. While POP hardens rapidly and is brittle, lime plaster sets slowly, allowing for flexibility and resistance to cracking over time.

Table of Comparison

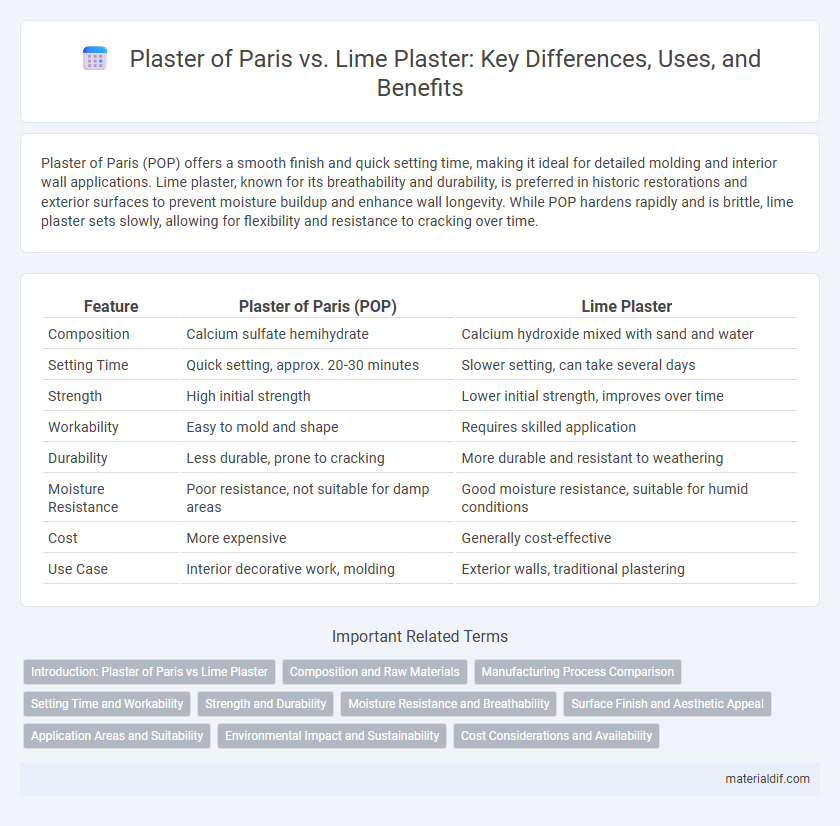

| Feature | Plaster of Paris (POP) | Lime Plaster |

|---|---|---|

| Composition | Calcium sulfate hemihydrate | Calcium hydroxide mixed with sand and water |

| Setting Time | Quick setting, approx. 20-30 minutes | Slower setting, can take several days |

| Strength | High initial strength | Lower initial strength, improves over time |

| Workability | Easy to mold and shape | Requires skilled application |

| Durability | Less durable, prone to cracking | More durable and resistant to weathering |

| Moisture Resistance | Poor resistance, not suitable for damp areas | Good moisture resistance, suitable for humid conditions |

| Cost | More expensive | Generally cost-effective |

| Use Case | Interior decorative work, molding | Exterior walls, traditional plastering |

Introduction: Plaster of Paris vs Lime Plaster

Plaster of Paris, a quick-setting material derived from gypsum, offers smooth finishes and rapid drying times ideal for intricate moldings and repairs. Lime plaster, made from lime putty and sand, provides superior breathability and flexibility, making it suitable for historic restorations and moisture-prone environments. The choice between Plaster of Paris and lime plaster hinges on application needs, drying time, and the surface's exposure conditions.

Composition and Raw Materials

Plaster of Paris primarily consists of calcium sulfate hemihydrate, derived from heating natural gypsum, whereas lime plaster is made from calcium hydroxide obtained by calcining limestone. The raw material for Plaster of Paris is more refined due to its controlled heating process, which results in faster setting times and smoother finishes. Lime plaster's raw materials and composition enable better breathability and flexibility, making it suitable for historic and ecological applications.

Manufacturing Process Comparison

Plaster of Paris is produced by heating natural gypsum to about 150degC, which removes water and creates a fine powder that quickly sets when mixed with water. In contrast, lime plaster is made by calcining limestone at around 900degC to form quicklime, which is then slaked with water to produce a workable paste. The manufacturing process of Plaster of Paris is faster and requires lower temperatures compared to the energy-intensive and lengthier procedure of producing lime plaster.

Setting Time and Workability

Plaster of Paris sets rapidly, typically within 10 to 15 minutes, offering quick hardening suitable for detailed moldings and repairs, while lime plaster requires several hours to days to fully set due to its carbonation process. The workability of plaster of Paris is limited by its fast setting time, necessitating swift application, whereas lime plaster provides extended workability, allowing for smoother finishes and adjustments. These differences make plaster of Paris ideal for rapid projects and lime plaster preferable for traditional, breathable wall coatings.

Strength and Durability

Plaster of Paris offers high compressive strength and quick setting time, making it ideal for detailed moldings and repairs, but it is less durable in moist conditions due to its brittle nature. Lime plaster, although slower to set, provides superior flexibility and long-term durability, with excellent resistance to weathering and moisture, making it suitable for exterior and historic restorations. The choice between Plaster of Paris and lime plaster depends largely on the specific structural requirements and environmental exposure of the application.

Moisture Resistance and Breathability

Plaster of Paris is less moisture resistant than lime plaster, making lime plaster ideal for humid environments due to its superior ability to repel water while allowing walls to breathe. Lime plaster's natural breathability prevents trapped moisture that can cause mold and structural damage, enhancing durability in damp conditions. The chemical composition of lime plaster facilitates vapor permeability, which improves indoor air quality compared to the more water-absorbent Plaster of Paris.

Surface Finish and Aesthetic Appeal

Plaster of Paris (POP) provides a smooth, fine-grained surface finish ideal for intricate decorative work and detailed moldings, enhancing interior aesthetics with its bright white appearance. Lime plaster offers a more textured, matte finish that develops a natural patina over time, contributing to a rustic and traditional charm in architectural settings. The choice between POP and lime plaster significantly impacts the visual appeal and tactile quality of walls and ceilings in construction and restoration projects.

Application Areas and Suitability

Plaster of Paris is ideal for interior applications such as decorative ceilings, moldings, and intricate wall designs due to its quick setting time and smooth finish. Lime plaster is more suitable for exterior surfaces and historic building restoration because of its breathability, flexibility, and resistance to moisture. Each plaster type serves distinct application needs, with Plaster of Paris excelling in fine, detailed work indoors and lime plaster providing durability and environmental compatibility outdoors.

Environmental Impact and Sustainability

Plaster of Paris, derived from gypsum, has a higher environmental footprint due to energy-intensive calcination and limited recyclability, whereas lime plaster is more sustainable, sourced from abundant limestone with lower processing emissions and natural carbonation that reabsorbs CO2 over time. Lime plaster's biodegradability and ability to regulate indoor humidity contribute to healthier building environments and reduced long-term ecological impact. Choosing lime plaster supports sustainable construction practices by promoting carbon neutrality and resource efficiency compared to the more disposable nature of Plaster of Paris.

Cost Considerations and Availability

Plaster of Paris (POP) generally costs more than lime plaster due to its chemical processing and manufacturing requirements, while lime plaster remains more economical with its natural, readily available raw materials such as limestone and sand. Availability plays a critical role: POP is widely used in urban areas and construction industries due to its quick-setting properties, whereas lime plaster is preferred in rural or traditional settings where access to materials and lower expenses are crucial. Cost efficiency and supply chain logistics influence the choice between these plasters, with lime plaster often favored for budget-conscious, eco-friendly projects.

Plaster of Paris vs Lime Plaster Infographic

materialdif.com

materialdif.com