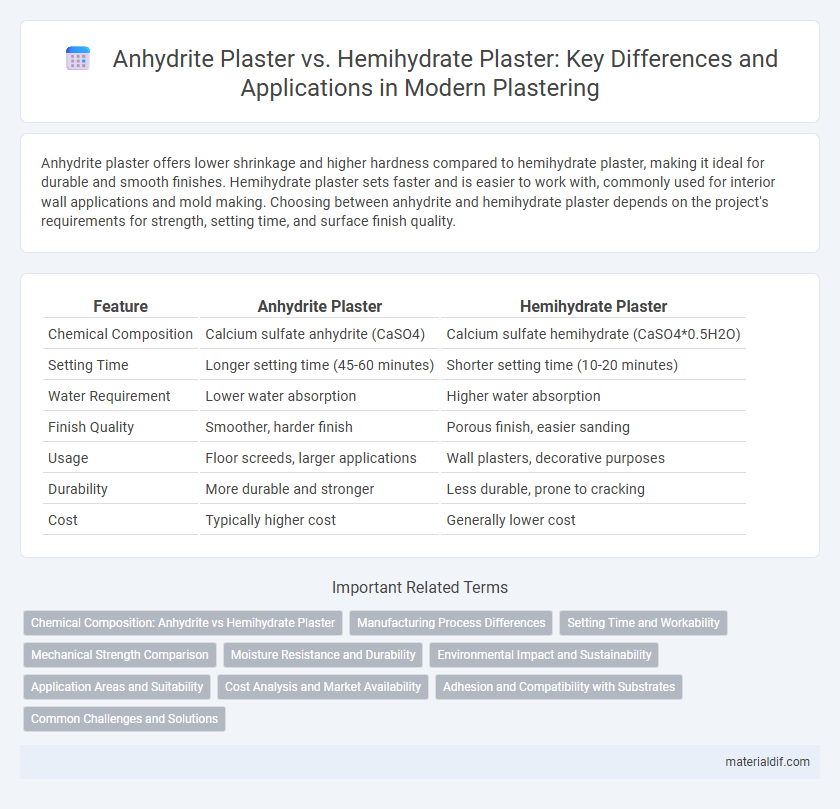

Anhydrite plaster offers lower shrinkage and higher hardness compared to hemihydrate plaster, making it ideal for durable and smooth finishes. Hemihydrate plaster sets faster and is easier to work with, commonly used for interior wall applications and mold making. Choosing between anhydrite and hemihydrate plaster depends on the project's requirements for strength, setting time, and surface finish quality.

Table of Comparison

| Feature | Anhydrite Plaster | Hemihydrate Plaster |

|---|---|---|

| Chemical Composition | Calcium sulfate anhydrite (CaSO4) | Calcium sulfate hemihydrate (CaSO4*0.5H2O) |

| Setting Time | Longer setting time (45-60 minutes) | Shorter setting time (10-20 minutes) |

| Water Requirement | Lower water absorption | Higher water absorption |

| Finish Quality | Smoother, harder finish | Porous finish, easier sanding |

| Usage | Floor screeds, larger applications | Wall plasters, decorative purposes |

| Durability | More durable and stronger | Less durable, prone to cracking |

| Cost | Typically higher cost | Generally lower cost |

Chemical Composition: Anhydrite vs Hemihydrate Plaster

Anhydrite plaster is primarily composed of calcium sulfate in its anhydrous form (CaSO4), lacking water molecules in its crystalline structure, while hemihydrate plaster consists of calcium sulfate hemihydrate (CaSO4*0.5H2O), containing chemically bound water. The chemical differences impact their setting reactions, with hemihydrate plaster rehydrating and crystallizing upon mixing with water, forming a rigid gypsum matrix, whereas anhydrite plaster sets through gradual hydration and crystallization without the expansion seen in hemihydrate plaster. These compositional variations influence properties such as setting time, strength, and moisture resistance critical for various construction and medical applications.

Manufacturing Process Differences

Anhydrite plaster is produced by calcining natural gypsum at lower temperatures, resulting in a dehydrated calcium sulfate form with minimal water content, whereas hemihydrate plaster is manufactured by heating gypsum to around 150degC, causing partial dehydration and forming calcium sulfate hemihydrate crystals. The anhydrite plaster process emphasizes slow cooling and grinding to retain anhydrous properties, contrasting with the hemihydrate method that involves rapid calcination and subsequent grinding to achieve a reactive powder for quick setting. These distinct manufacturing techniques lead to differences in setting time, strength, and application suitability between anhydrite and hemihydrate plasters.

Setting Time and Workability

Anhydrite plaster exhibits a slower setting time compared to hemihydrate plaster, allowing more extended working periods which enhance workability for complex applications. Hemihydrate plaster sets rapidly, making it ideal for fast projects but requires quick and precise handling to avoid premature hardening. The higher water demand of anhydrite plaster contributes to its smoother texture and better adhesion, while hemihydrate plaster's quicker set time suits environments needing rapid turnaround.

Mechanical Strength Comparison

Anhydrite plaster exhibits higher mechanical strength compared to hemihydrate plaster due to its denser crystalline structure, resulting in improved durability and load-bearing capacity. Hemihydrate plaster, while quicker to set, has lower compressive strength and is more prone to cracking under stress. Choosing anhydrite plaster enhances the longevity and stability of construction projects requiring robust plaster materials.

Moisture Resistance and Durability

Anhydrite plaster offers superior moisture resistance compared to hemihydrate plaster due to its lower water absorption properties, making it ideal for humid environments and areas prone to dampness. Hemihydrate plaster, while faster setting, tends to be less durable in wet conditions and may require additional waterproofing measures to enhance its longevity. The denser crystalline structure of anhydrite plaster contributes to increased durability and resistance against cracking over time.

Environmental Impact and Sustainability

Anhydrite plaster, sourced from natural gypsum, has a lower carbon footprint due to less energy-intensive production compared to hemihydrate plaster, which requires calcination at high temperatures. Anhydrite offers better sustainability by minimizing CO2 emissions and reducing energy consumption across the manufacturing process. Hemihydrate plaster generates more waste and has a greater environmental impact associated with mining and processing, making anhydrite a more eco-friendly option for sustainable construction.

Application Areas and Suitability

Anhydrite plaster is widely used in flooring and large-area applications due to its low shrinkage and excellent moisture resistance, making it suitable for underfloor heating systems. Hemihydrate plaster, known as gypsum plaster, is ideal for interior wall finishing and decorative molds because of its quick setting time and smooth finish. Selecting between anhydrite and hemihydrate plaster depends on project requirements such as drying time, moisture exposure, and surface finish quality.

Cost Analysis and Market Availability

Anhydrite plaster generally costs more than hemihydrate plaster due to its lower availability and specialized production process, making it less common in standard construction markets. Hemihydrate plaster, widely used and mass-produced, offers a cost-effective solution with broad market availability in building supply chains worldwide. Price fluctuations for anhydrite plaster often depend on regional demand and raw material sourcing, impacting its accessibility compared to the more stable pricing and distribution of hemihydrate plaster.

Adhesion and Compatibility with Substrates

Anhydrite plaster exhibits superior adhesion to a variety of substrates due to its fine particle size and smoother surface finish, enhancing bond strength with base materials such as stone, brick, and concrete. Hemihydrate plaster tends to have faster setting times but may require additives or surface preparation to improve compatibility with porous or uneven substrates. The chemical composition of anhydrite plaster allows better moisture regulation, which contributes to its consistent compatibility and long-lasting adhesion in diverse construction applications.

Common Challenges and Solutions

Anhydrite plaster often faces slow setting times and sensitivity to moisture, leading to cracking and reduced durability, while hemihydrate plaster encounters issues with rapid setting and shrinkage, causing surface brittleness. Solutions include adding retarders like citric acid to anhydrite plaster to control setting and employing plasticizers in hemihydrate plaster for improved workability and reduced shrinkage. Proper mixing ratios, controlled curing environments, and the use of additives tailored to each plaster type enhance performance and minimize common challenges in construction applications.

Anhydrite Plaster vs Hemihydrate Plaster Infographic

materialdif.com

materialdif.com