Ready-mix plaster offers consistent quality and faster application due to precise factory blending, reducing on-site labor and material waste. On-site mixed plaster allows customization to specific project needs but can result in variable consistency and longer preparation times. Choosing between the two depends on project scale, budget, and quality control requirements.

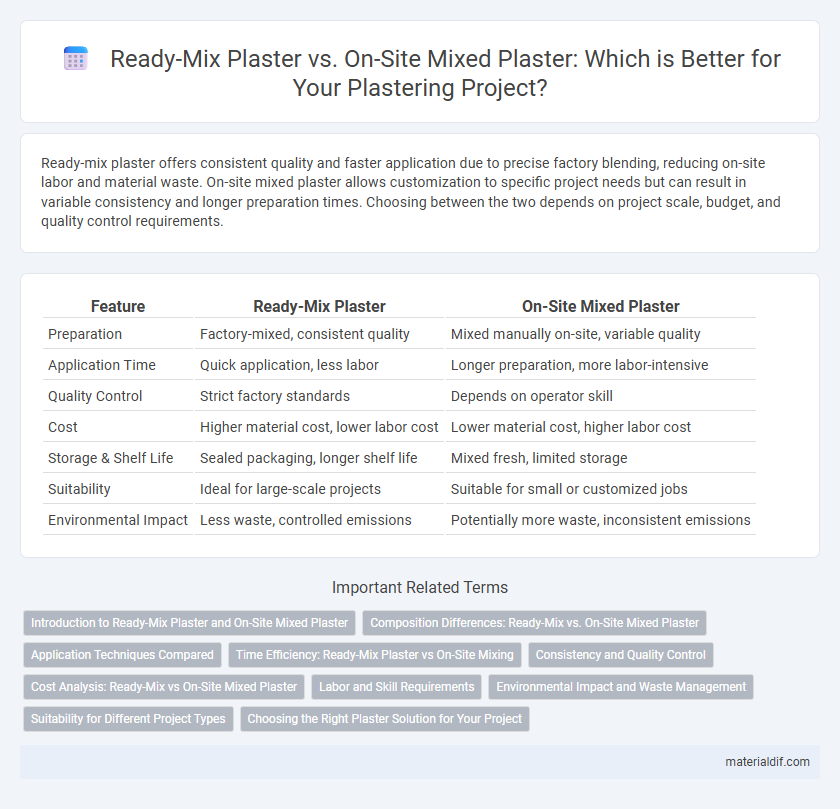

Table of Comparison

| Feature | Ready-Mix Plaster | On-Site Mixed Plaster |

|---|---|---|

| Preparation | Factory-mixed, consistent quality | Mixed manually on-site, variable quality |

| Application Time | Quick application, less labor | Longer preparation, more labor-intensive |

| Quality Control | Strict factory standards | Depends on operator skill |

| Cost | Higher material cost, lower labor cost | Lower material cost, higher labor cost |

| Storage & Shelf Life | Sealed packaging, longer shelf life | Mixed fresh, limited storage |

| Suitability | Ideal for large-scale projects | Suitable for small or customized jobs |

| Environmental Impact | Less waste, controlled emissions | Potentially more waste, inconsistent emissions |

Introduction to Ready-Mix Plaster and On-Site Mixed Plaster

Ready-mix plaster is factory-prepared, ensuring consistent quality and saving time on construction sites by eliminating the need for manual mixing. On-site mixed plaster requires combining raw materials such as cement, sand, and water at the construction location, which allows for customization but may lead to variability in texture and strength. Choosing between ready-mix plaster and on-site mixed plaster depends on project scale, quality control requirements, and labor availability.

Composition Differences: Ready-Mix vs. On-Site Mixed Plaster

Ready-mix plaster consists of pre-mixed ingredients including cement, lime, sand, and additives such as polymers and fiber reinforcements, ensuring consistent quality and enhanced workability. On-site mixed plaster uses raw materials like sand, cement, lime, and water combined manually, which can lead to variations in texture and strength due to inconsistent mixing ratios. The controlled composition of ready-mix plaster improves durability and reduces the risk of cracking compared to the variable quality of on-site mixed plaster.

Application Techniques Compared

Ready-mix plaster offers consistent quality and faster application due to its pre-measured ingredients and factory-controlled mixing process, ensuring minimal batch-to-batch variation. On-site mixed plaster allows for customization in water-cement ratios and additives based on specific project needs but requires skilled labor to maintain consistency and avoid common issues like cracking or uneven texture. Application techniques for ready-mix plaster typically involve straightforward troweling and spraying methods, while on-site mixing demands thorough blending and immediate use to achieve optimal setting and adhesion.

Time Efficiency: Ready-Mix Plaster vs On-Site Mixing

Ready-mix plaster offers superior time efficiency by eliminating the need for on-site measuring, mixing, and quality control, enabling faster application and reducing labor costs. On-site mixed plaster requires manual blending of materials, which can lead to inconsistencies and extended preparation times, impacting overall project timelines. Construction projects benefit from ready-mix plaster's precise formulation and rapid deployment, improving scheduling accuracy and accelerating completion.

Consistency and Quality Control

Ready-mix plaster offers superior consistency and quality control due to its precise factory-based production processes, ensuring uniform mixture proportions and minimal variability. On-site mixed plaster can suffer from inconsistent water-to-powder ratios and mixing times, leading to variable adhesion and finishing quality. The controlled environment of ready-mix plaster reduces human error and contamination, resulting in a more reliable and durable surface finish.

Cost Analysis: Ready-Mix vs On-Site Mixed Plaster

Ready-mix plaster typically incurs higher upfront costs due to factory processing and packaging, but reduces labor expenses and material wastage on-site, leading to potential long-term savings. On-site mixed plaster often demands lower initial outlay for materials but can increase overall costs through inconsistent quality, longer application times, and higher labor requirements. Cost analysis must consider project scale, labor rates, and quality control for optimal decision-making between ready-mix and on-site mixed plaster.

Labor and Skill Requirements

Ready-mix plaster reduces labor intensity and requires less skilled workforce compared to on-site mixed plaster, as it comes pre-mixed with consistent quality and composition. On-site mixed plaster demands experienced laborers to manually blend materials accurately, increasing the potential for inconsistency and labor costs. Choosing ready-mix plaster enhances efficiency on construction sites, especially when skilled labor availability is limited.

Environmental Impact and Waste Management

Ready-mix plaster significantly reduces environmental impact by minimizing raw material overuse and packaging waste through precise factory-controlled production. On-site mixed plaster generates higher waste due to inconsistent batching and excess leftover material, leading to increased disposal challenges and resource inefficiency. Efficient waste management in ready-mix plaster promotes sustainable construction practices by lowering carbon emissions and reducing landfill contributions.

Suitability for Different Project Types

Ready-mix plaster offers consistent quality and faster application, making it ideal for large-scale commercial projects with tight timelines and standardized requirements. On-site mixed plaster provides flexibility in mix ratios, allowing customization for small residential or renovation projects where specific texture or finish variations are needed. Choosing between the two depends on project size, complexity, and the demand for uniformity versus adaptability.

Choosing the Right Plaster Solution for Your Project

Ready-mix plaster offers consistent quality and faster application due to its controlled production process, making it ideal for large-scale projects with tight deadlines. On-site mixed plaster provides flexibility in mix proportions suited for specific project requirements but may lead to variable results depending on skilled labor availability. Evaluating project size, timeline, and quality control needs is essential when choosing between ready-mix and on-site mixed plaster solutions.

Ready-Mix Plaster vs On-Site Mixed Plaster Infographic

materialdif.com

materialdif.com