Hydrated lime plaster is made from lime putty mixed with sand and water, offering excellent breathability and flexibility, ideal for interior walls and historic building restoration. Hydraulic lime plaster, containing natural cementing agents, sets through a chemical reaction with water, providing greater strength and water resistance, suitable for exterior applications and damp environments. Choosing between the two depends on the required durability, moisture exposure, and the specific needs of the construction or restoration project.

Table of Comparison

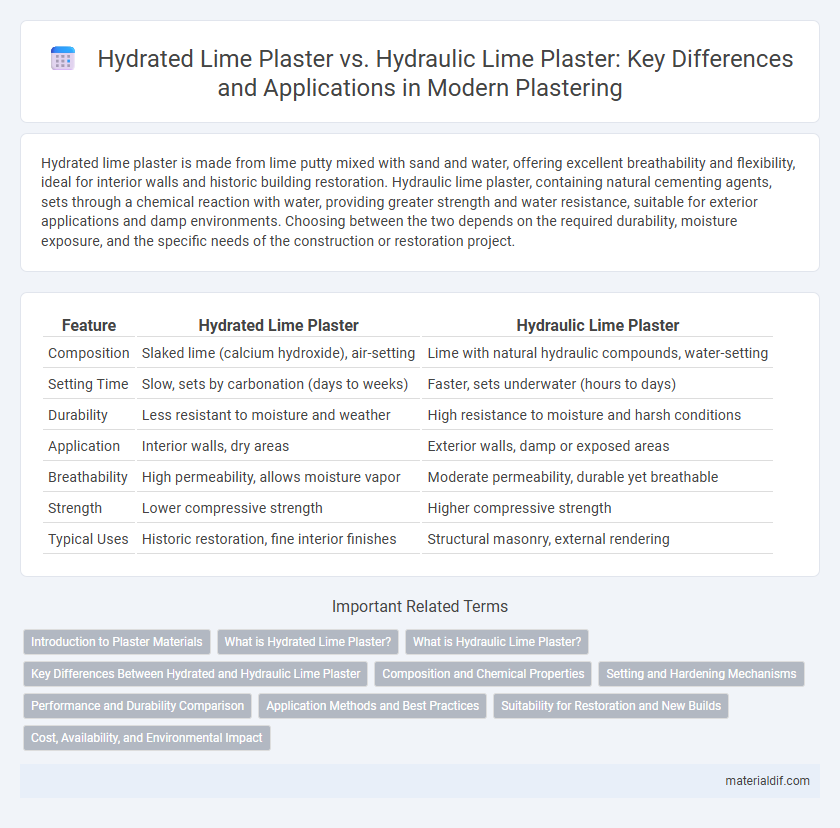

| Feature | Hydrated Lime Plaster | Hydraulic Lime Plaster |

|---|---|---|

| Composition | Slaked lime (calcium hydroxide), air-setting | Lime with natural hydraulic compounds, water-setting |

| Setting Time | Slow, sets by carbonation (days to weeks) | Faster, sets underwater (hours to days) |

| Durability | Less resistant to moisture and weather | High resistance to moisture and harsh conditions |

| Application | Interior walls, dry areas | Exterior walls, damp or exposed areas |

| Breathability | High permeability, allows moisture vapor | Moderate permeability, durable yet breathable |

| Strength | Lower compressive strength | Higher compressive strength |

| Typical Uses | Historic restoration, fine interior finishes | Structural masonry, external rendering |

Introduction to Plaster Materials

Hydrated lime plaster is composed of calcium hydroxide and offers excellent breathability and flexibility, making it ideal for interior surfaces prone to moisture. Hydraulic lime plaster contains calcium silicates that set through hydrolysis, providing superior strength and durability suitable for exterior applications exposed to weather. Both materials are essential in traditional and restoration plastering, each selected based on structural needs and environmental conditions.

What is Hydrated Lime Plaster?

Hydrated lime plaster is a building material composed primarily of calcium hydroxide, produced by treating quicklime with water. It offers excellent breathability and flexibility, making it ideal for historic building restoration and interior applications where moisture regulation is crucial. Unlike hydraulic lime plaster, it sets slowly through carbonation, requiring longer curing times and is best suited for non-structural surfaces.

What is Hydraulic Lime Plaster?

Hydraulic lime plaster is a natural building material made from lime that sets through a chemical reaction with water, unlike hydrated lime plaster which hardens by carbonation with air. It contains hydraulic lime, which has clay and silica components, allowing it to cure underwater and gain strength faster, making it suitable for damp or exterior applications. This plaster provides durability, breathability, and flexibility, essential for preserving historic structures while preventing moisture damage.

Key Differences Between Hydrated and Hydraulic Lime Plaster

Hydrated lime plaster primarily consists of calcium hydroxide and sets slowly by carbonating with carbon dioxide in the air, offering flexibility and breathability for interior surfaces. Hydraulic lime plaster contains natural hydraulic lime that sets through a chemical reaction with water, providing faster setting times and increased durability suitable for exterior and damp environments. Key differences include their setting mechanisms, water resistance, and suitability for various construction conditions.

Composition and Chemical Properties

Hydrated lime plaster consists mainly of calcium hydroxide, derived from quicklime and mixed with water to create a smooth, workable paste with slow carbonation and strong breathability. Hydraulic lime plaster contains calcium silicates and aluminates, allowing it to set through a chemical reaction with water, resulting in faster curing and improved water resistance. The key chemical distinction lies in hydrated lime's reliance on carbonation for hardening, while hydraulic lime undergoes hydraulic setting, making it suitable for damp environments.

Setting and Hardening Mechanisms

Hydrated lime plaster sets primarily through carbonation, where calcium hydroxide reacts with carbon dioxide in the air to form calcium carbonate, resulting in a slower hardening process. Hydraulic lime plaster contains reactive silica and alumina, allowing it to set through hydration, forming strong, insoluble calcium silicates and aluminates that cure faster and under wet conditions. This makes hydraulic lime plaster preferable for environments exposed to moisture, while hydrated lime plaster is better suited for dry, indoor applications.

Performance and Durability Comparison

Hydrated lime plaster offers excellent breathability and flexibility, making it suitable for interior applications with moderate moisture exposure. Hydraulic lime plaster, containing natural hydraulic binders, provides superior strength and faster setting times, enhancing durability in exterior and damp environments. The choice between them depends on specific performance requirements, with hydraulic lime plaster preferred for structural resilience and weather resistance.

Application Methods and Best Practices

Hydrated lime plaster, typically applied in thin coats with trowels or hawks, requires multiple layers and extended curing times to achieve breathability and flexibility, making it ideal for historic building restoration. Hydraulic lime plaster, composed of natural hydraulic lime that sets through hydration, allows for faster setting and higher moisture resistance, suitable for exterior applications and damp environments. Best practices involve applying hydraulic lime plaster in warmer temperatures for optimal curing, while hydrated lime plaster benefits from maintaining moisture during drying to prevent cracking and ensure durability.

Suitability for Restoration and New Builds

Hydrated lime plaster offers excellent breathability and flexibility, making it highly suitable for restoring historic buildings where moisture control and gentle curing are critical. Hydraulic lime plaster sets through a chemical reaction with water, providing superior strength and durability ideal for new builds exposed to harsher weather conditions. Both plasters are eco-friendly options, but hydraulic lime's faster setting time and robustness make it preferable for structural applications, while hydrated lime is favored in preservation for its compatibility with old masonry.

Cost, Availability, and Environmental Impact

Hydrated lime plaster generally costs less and is more readily available than hydraulic lime plaster, making it a common choice for budget-conscious projects. Hydraulic lime plaster, while typically more expensive, offers superior durability and sets faster due to its chemical properties, reducing long-term maintenance costs. From an environmental perspective, hydrated lime plaster has a lower carbon footprint because it requires less energy to produce, whereas hydraulic lime plaster's manufacturing process emits more CO2 but provides greater longevity, potentially offsetting its initial impact.

Hydrated Lime Plaster vs Hydraulic Lime Plaster Infographic

materialdif.com

materialdif.com