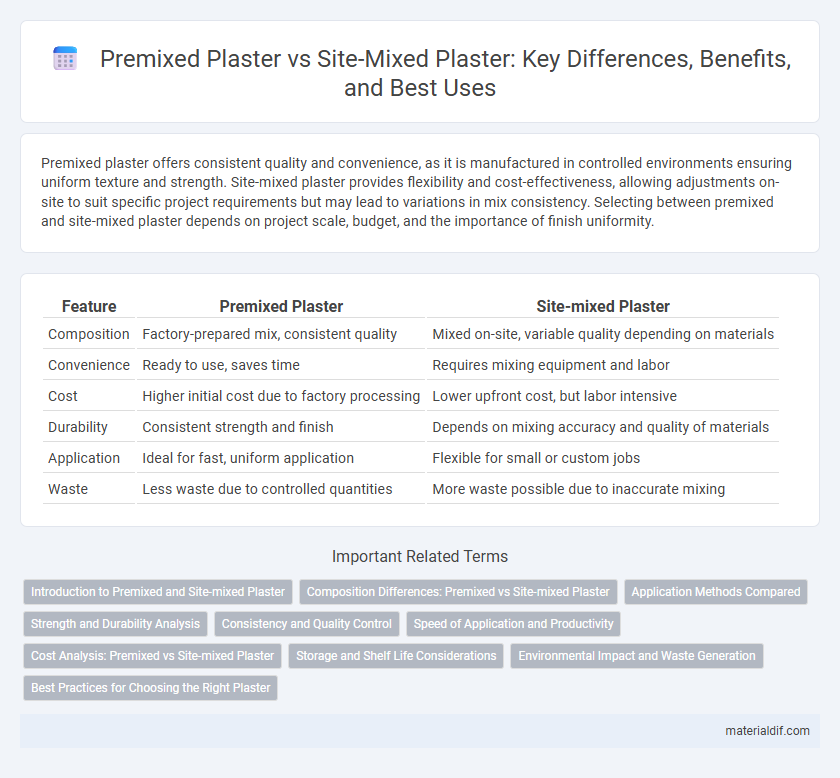

Premixed plaster offers consistent quality and convenience, as it is manufactured in controlled environments ensuring uniform texture and strength. Site-mixed plaster provides flexibility and cost-effectiveness, allowing adjustments on-site to suit specific project requirements but may lead to variations in mix consistency. Selecting between premixed and site-mixed plaster depends on project scale, budget, and the importance of finish uniformity.

Table of Comparison

| Feature | Premixed Plaster | Site-mixed Plaster |

|---|---|---|

| Composition | Factory-prepared mix, consistent quality | Mixed on-site, variable quality depending on materials |

| Convenience | Ready to use, saves time | Requires mixing equipment and labor |

| Cost | Higher initial cost due to factory processing | Lower upfront cost, but labor intensive |

| Durability | Consistent strength and finish | Depends on mixing accuracy and quality of materials |

| Application | Ideal for fast, uniform application | Flexible for small or custom jobs |

| Waste | Less waste due to controlled quantities | More waste possible due to inaccurate mixing |

Introduction to Premixed and Site-mixed Plaster

Premixed plaster is manufactured under controlled factory conditions, ensuring consistent quality, uniform texture, and quick application, which reduces labor time on-site. Site-mixed plaster involves blending raw materials like cement, sand, and lime directly at the construction site, offering flexibility in mix ratios tailored to specific project requirements. The choice between premixed and site-mixed plaster depends on factors such as project scale, desired finish quality, and budget considerations.

Composition Differences: Premixed vs Site-mixed Plaster

Premixed plaster consists of a factory-prepared blend of cement, lime, sand, and additives, ensuring consistent composition and quality control. Site-mixed plaster is manually combined onsite, typically using raw materials like cement, lime, and sand in varying proportions, which can lead to inconsistencies in texture and strength. The uniformity of premixed plaster enhances durability and reduces the risk of human error during mixing, while site-mixed plaster offers flexibility in adjusting mix ratios to specific project requirements.

Application Methods Compared

Premixed plaster offers a consistent mixture with minimal preparation, allowing for quicker and more efficient application using standard trowels and spray machines. Site-mixed plaster requires manual batching and mixing, which can lead to variability in texture and setting times, demanding skilled labor for proper application. The uniform consistency of premixed plaster reduces the risk of cracks and surface defects compared to the variability inherent in site-mixed plaster applications.

Strength and Durability Analysis

Premixed plaster offers consistent strength and enhanced durability due to factory-controlled proportions and quality of raw materials, ensuring uniform bonding and reduced shrinkage cracks. Site-mixed plaster strength and durability vary significantly based on manual mixing accuracy, water-cement ratio, and workmanship, often leading to weaker adhesion and more frequent surface defects. For long-term structural performance, premixed plaster provides more reliable resistance to weathering and mechanical stress compared to site-mixed alternatives.

Consistency and Quality Control

Premixed plaster offers superior consistency due to factory-controlled mixing ratios and quality assurance processes, ensuring a uniform texture and strength in every batch. Site-mixed plaster often varies in quality depending on the precision of material measurement, mixing time, and environmental conditions, leading to potential inconsistencies in setting time and durability. Reliable quality control in premixed plaster reduces the risk of cracking and uneven surfaces, optimizing overall finishing performance on construction projects.

Speed of Application and Productivity

Premixed plaster offers superior speed of application compared to site-mixed plaster due to its ready-to-use formulation, eliminating the need for on-site mixing and reducing labor time. This efficiency enhances overall productivity by enabling faster project completion and minimizing delays caused by mixing inconsistencies. Site-mixed plaster often requires more preparation time and skilled labor, which can slow down the workflow and impact productivity negatively.

Cost Analysis: Premixed vs Site-mixed Plaster

Premixed plaster typically incurs higher initial costs due to factory processing and packaging but offers savings in labor and reduced material wastage. Site-mixed plaster tends to be more economical upfront as raw materials like cement, sand, and lime are purchased separately, though it requires skilled labor and careful batching to maintain quality, potentially increasing overall expenses. Evaluating total costs should consider not only material prices but also labor efficiency, consistency, and the likelihood of rework.

Storage and Shelf Life Considerations

Premixed plaster offers superior shelf life and convenient storage, as it is factory-sealed in moisture-resistant packaging that maintains its quality over extended periods. Site-mixed plaster requires careful storage of raw materials like cement and sand to avoid moisture exposure, which can degrade components and reduce effectiveness. Proper storage conditions for premixed plaster minimize contamination and waste, ensuring consistent application performance on construction sites.

Environmental Impact and Waste Generation

Premixed plaster significantly reduces environmental impact by minimizing raw material consumption and ensuring precise mixing, which lowers waste generation compared to site-mixed plaster. Site-mixed plaster often leads to excess material usage and higher carbon emissions due to on-site preparation inefficiencies. Sustainable construction practices favor premixed plaster for its consistent quality and reduced waste disposal needs.

Best Practices for Choosing the Right Plaster

Premixed plaster ensures consistent quality and time efficiency, making it ideal for projects requiring uniformity and speed, while site-mixed plaster offers flexibility in adjusting mix ratios for specific site conditions or custom finishes. Selecting the right plaster depends on factors such as project scale, desired finish, environmental conditions, and labor expertise. Best practices include evaluating project requirements, verifying material standards, and considering cost implications to optimize durability and aesthetics.

Premixed Plaster vs Site-mixed Plaster Infographic

materialdif.com

materialdif.com