Hydraulic lime plaster sets through a chemical reaction with water, making it suitable for damp or external surfaces due to its faster curing time and increased durability. Non-hydraulic lime plaster dries by carbonation, requiring exposure to air and longer curing periods, which limits its use to interior, well-ventilated areas. Choosing between hydraulic and non-hydraulic lime plaster depends on the project's moisture conditions and desired strength, with hydraulic lime offering enhanced resistance to water and weathering.

Table of Comparison

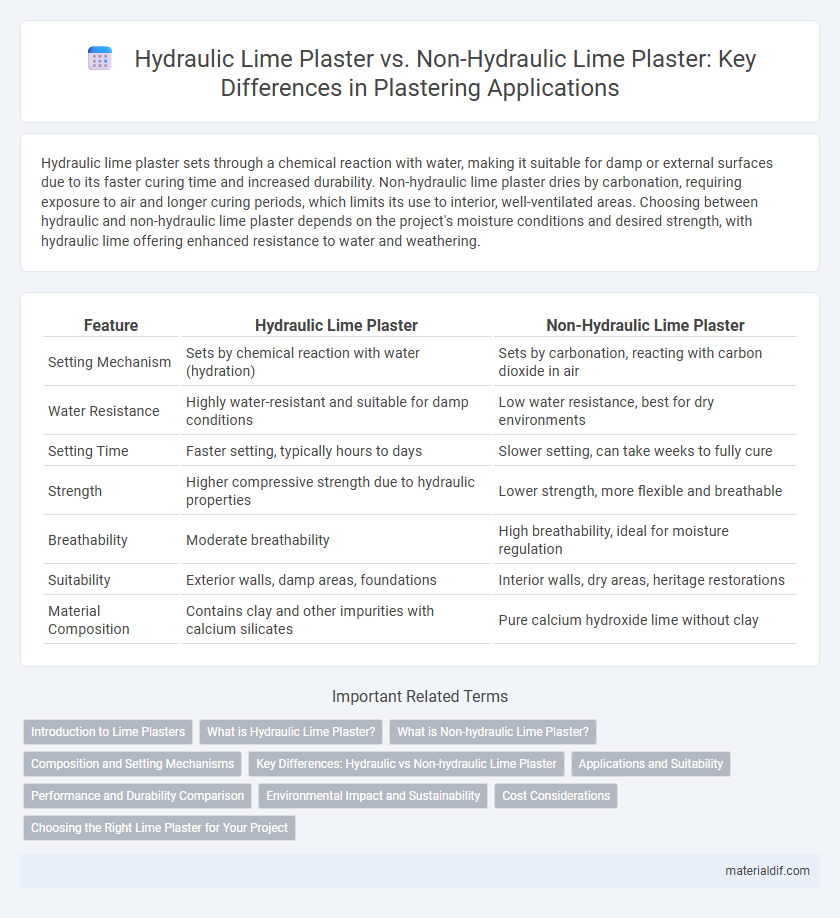

| Feature | Hydraulic Lime Plaster | Non-Hydraulic Lime Plaster |

|---|---|---|

| Setting Mechanism | Sets by chemical reaction with water (hydration) | Sets by carbonation, reacting with carbon dioxide in air |

| Water Resistance | Highly water-resistant and suitable for damp conditions | Low water resistance, best for dry environments |

| Setting Time | Faster setting, typically hours to days | Slower setting, can take weeks to fully cure |

| Strength | Higher compressive strength due to hydraulic properties | Lower strength, more flexible and breathable |

| Breathability | Moderate breathability | High breathability, ideal for moisture regulation |

| Suitability | Exterior walls, damp areas, foundations | Interior walls, dry areas, heritage restorations |

| Material Composition | Contains clay and other impurities with calcium silicates | Pure calcium hydroxide lime without clay |

Introduction to Lime Plasters

Hydraulic lime plaster sets through a chemical reaction with water, allowing it to cure underwater and gain strength quickly, making it ideal for damp or external environments. Non-hydraulic lime plaster hardens by carbonation, absorbing carbon dioxide from the air, which requires longer curing times and is best suited for internal, dry conditions. Both types offer breathable, flexible finishes that accommodate building movement and moisture regulation, essential for historic and sustainable construction.

What is Hydraulic Lime Plaster?

Hydraulic lime plaster is a breathable, durable material that sets through a chemical reaction with water, allowing it to harden even in damp conditions. Unlike non-hydraulic lime plaster, it contains natural clay and silica, which enable it to cure underwater or in high humidity environments. This plaster is widely used for external masonry and restoration projects due to its water-resistant and structural properties.

What is Non-hydraulic Lime Plaster?

Non-hydraulic lime plaster is a type of lime plaster made from pure lime putty that sets and hardens through carbonation with carbon dioxide in the air. Unlike hydraulic lime plaster, it does not contain silica or clay and requires prolonged exposure to air to cure properly. This plaster is highly breathable and flexible, making it ideal for historic building restoration where moisture regulation is critical.

Composition and Setting Mechanisms

Hydraulic lime plaster contains clay and silica, enabling it to set through a chemical reaction with water, which provides faster and stronger curing even in damp conditions. Non-hydraulic lime plaster primarily consists of pure calcium hydroxide, relying on carbonation by absorbing carbon dioxide from the air to harden over an extended drying period. The presence of pozzolanic materials in hydraulic lime imparts hydraulic properties, while non-hydraulic lime's setting mechanism is slower and dependent on atmospheric moisture.

Key Differences: Hydraulic vs Non-hydraulic Lime Plaster

Hydraulic lime plaster sets through a chemical reaction with water, enabling it to harden underwater and making it suitable for exterior or damp environments, while non-hydraulic lime plaster relies on carbon dioxide from the air to carbonate and harden, ideal for breathable interior walls. The compressive strength of hydraulic lime plaster is higher, offering better durability and resistance to moisture compared to the softer, more flexible non-hydraulic lime plaster. Hydraulic lime plaster contains clay and other impurities that trigger hydraulic setting, whereas non-hydraulic lime plaster is purer and slower to set, requiring longer curing times.

Applications and Suitability

Hydraulic lime plaster sets through a chemical reaction with water, making it ideal for exterior applications and damp environments due to its water-resistant properties. Non-hydraulic lime plaster relies on carbonation by air to harden, offering excellent breathability and flexibility, which suits interior walls and historic building restoration. Choosing between hydraulic and non-hydraulic lime plaster depends on the exposure to moisture and the need for durability versus vapor permeability.

Performance and Durability Comparison

Hydraulic lime plaster sets through a chemical reaction with water, providing superior performance in damp environments and faster curing times compared to non-hydraulic lime plaster, which relies on carbonation and air exposure to harden. Hydraulic lime plaster offers enhanced durability, resisting water penetration, frost damage, and structural movement, making it ideal for exterior applications and restoration projects on historic buildings. Non-hydraulic lime plaster, while more breathable and flexible, has lower mechanical strength and longer drying periods, limiting its use primarily to interior, dry environments where moisture resistance is less critical.

Environmental Impact and Sustainability

Hydraulic lime plaster, which sets through a chemical reaction with water, offers enhanced durability and weather resistance, reducing the need for frequent repairs and lowering long-term environmental impact. Non-hydraulic lime plaster, relying on carbonation with carbon dioxide in the air, has a slower curing process but is highly breathable and often sourced with minimal processing, promoting natural sustainability. Choosing hydraulic lime plaster supports projects exposed to moisture, while non-hydraulic varieties are ideal for interior, low-moisture applications prioritizing ecological balance and low embodied energy.

Cost Considerations

Hydraulic lime plaster generally incurs higher costs due to its complex manufacturing process and superior durability, making it ideal for exterior applications exposed to moisture. Non-hydraulic lime plaster is more affordable and easier to produce, but it requires longer curing times and is best suited for interior use with limited exposure to water. Budget decisions should balance upfront material costs against long-term maintenance and environmental factors for optimal performance.

Choosing the Right Lime Plaster for Your Project

Hydraulic lime plaster offers superior durability and water resistance due to its ability to set under water, making it ideal for exterior applications and damp environments. Non-hydraulic lime plaster, which sets through carbonation with air, provides greater breathability and flexibility, suitable for historic restoration and interior walls. Selecting the right lime plaster depends on factors like exposure to moisture, desired breathability, and compatibility with existing materials to ensure long-lasting, effective results.

Hydraulic Lime Plaster vs Non-hydraulic Lime Plaster Infographic

materialdif.com

materialdif.com