Plaster of Paris (POP) is a quick-setting material made by heating gypsum to remove water, resulting in fine powder that hardens rapidly when mixed with water, ideal for detailed molds and decorative finishes. Gypsum plaster, derived directly from natural gypsum rock, contains more water content and sets slower, making it suitable for general wall plastering with better breathability and moisture regulation. Both materials offer fire resistance and ease of application, but POP is preferred for precision work while gypsum plaster is favored for larger surface areas due to its workability.

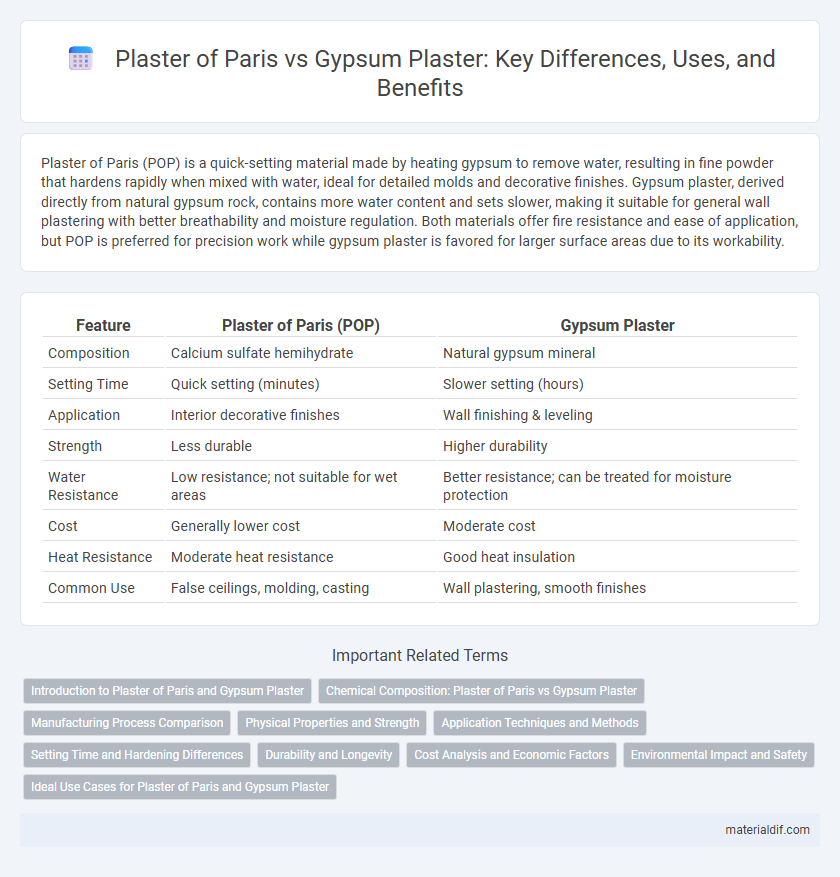

Table of Comparison

| Feature | Plaster of Paris (POP) | Gypsum Plaster |

|---|---|---|

| Composition | Calcium sulfate hemihydrate | Natural gypsum mineral |

| Setting Time | Quick setting (minutes) | Slower setting (hours) |

| Application | Interior decorative finishes | Wall finishing & leveling |

| Strength | Less durable | Higher durability |

| Water Resistance | Low resistance; not suitable for wet areas | Better resistance; can be treated for moisture protection |

| Cost | Generally lower cost | Moderate cost |

| Heat Resistance | Moderate heat resistance | Good heat insulation |

| Common Use | False ceilings, molding, casting | Wall plastering, smooth finishes |

Introduction to Plaster of Paris and Gypsum Plaster

Plaster of Paris (POP) is a quick-setting material derived from heating gypsum to about 150degC, which removes water content, resulting in a fine white powder used for smooth finishes and decorative purposes. Gypsum plaster, directly made by grinding natural gypsum, retains more moisture and sets slower than POP, offering greater workability and moisture resistance in construction. Both plaster types are widely used in interior wall finishes, but POP provides faster setting time, while gypsum plaster ensures better durability and breathability.

Chemical Composition: Plaster of Paris vs Gypsum Plaster

Plaster of Paris consists primarily of calcium sulfate hemihydrate (CaSO4* 1/2H2O), produced by heating gypsum to remove water. Gypsum plaster retains calcium sulfate dihydrate (CaSO4*2H2O), maintaining more water content and a slower setting time compared to Plaster of Paris. The chemical difference directly affects drying speed, strength, and application properties in construction and decorative finishes.

Manufacturing Process Comparison

Plaster of Paris is produced by heating natural gypsum to about 150degC, driving off water molecules to form a fine powder that rehydrates quickly when mixed with water. Gypsum plaster is manufactured by grinding natural gypsum rock directly without calcination, maintaining its original chemical structure and slower setting time. The calcination in Plaster of Paris results in faster setting and increased strength, while gypsum plaster retains higher moisture content and better workability.

Physical Properties and Strength

Plaster of Paris (POP) exhibits a rapid setting time and hardens quickly, making it ideal for detailed molding and casting, but it has lower water resistance and strength compared to gypsum plaster. Gypsum plaster offers a slower setting time, allowing for easier application over larger surfaces, with enhanced durability, higher compressive strength, and better moisture resistance due to its natural composition of calcium sulfate dihydrate. Both materials are calcium sulfate-based, but gypsum plaster's crystalline structure provides superior mechanical properties and long-term stability in construction applications.

Application Techniques and Methods

Plaster of Paris is favored for intricate moldings and rapid setting applications due to its fine texture and quick hardening properties, making it ideal for detailed decorative work and emergency repairs. Gypsum plaster offers superior moisture resistance and is applied in thicker coats using trowels or spray techniques in interior wall finishes and ceilings, enhancing durability and smoothness. Both materials require surface preparation and curing methods tailored to their setting times and moisture sensitivities to ensure optimal adhesion and finish.

Setting Time and Hardening Differences

Plaster of Paris (POP) sets rapidly, typically within 10 to 15 minutes, due to its chemically reactive hemihydrate gypsum content that hardens quickly upon mixing with water. Gypsum plaster, on the other hand, has a slower setting time, often ranging from 30 minutes to several hours, allowing for more workability and adjustments during application. The rapid hardening of POP makes it ideal for fast repairs and mould creation, whereas gypsum plaster's longer curing period provides better finish control and durability in construction.

Durability and Longevity

Plaster of Paris (POP) sets quickly but is less resistant to moisture, making it less durable in humid environments compared to Gypsum plaster. Gypsum plaster offers enhanced durability and longevity due to its excellent moisture resistance and slower setting time, which reduces cracking over time. For long-lasting interior finishes, gypsum plaster is preferred, especially in areas prone to dampness.

Cost Analysis and Economic Factors

Plaster of Paris (POP) generally costs more than gypsum plaster due to its higher processing requirements and quicker setting time, impacting overall project budgets. Gypsum plaster, derived from natural gypsum, offers a more economical solution with lower material and labor costs, making it ideal for large-scale construction. Economic factors such as durability, ease of application, and waste reduction also influence cost-effectiveness, with gypsum plaster providing better long-term savings in most building projects.

Environmental Impact and Safety

Plaster of Paris (POP) generates significant CO2 emissions during its manufacturing process, contributing to higher environmental impact compared to gypsum plaster, which is more eco-friendly due to its natural mineral origin and lower energy requirement. Gypsum plaster poses fewer health risks as it emits less dust and contains fewer toxic substances, making it safer for indoor use and reducing respiratory issues for workers. The biodegradable nature of gypsum plaster also facilitates sustainable construction practices, contrasting with POP's slower decomposition and potential chemical hazards.

Ideal Use Cases for Plaster of Paris and Gypsum Plaster

Plaster of Paris is ideal for creating intricate molds, sculptures, and smooth, quick-setting wall finishes due to its rapid hardening properties. Gypsum plaster is best suited for interior wall and ceiling applications where a breathable, moisture-resistant finish is required, providing durability and ease of application. Both materials serve distinct construction needs, with Plaster of Paris excelling in artistic and detailed work, while gypsum plaster offers practicality and longevity in building interiors.

Plaster of Paris vs Gypsum Plaster Infographic

materialdif.com

materialdif.com