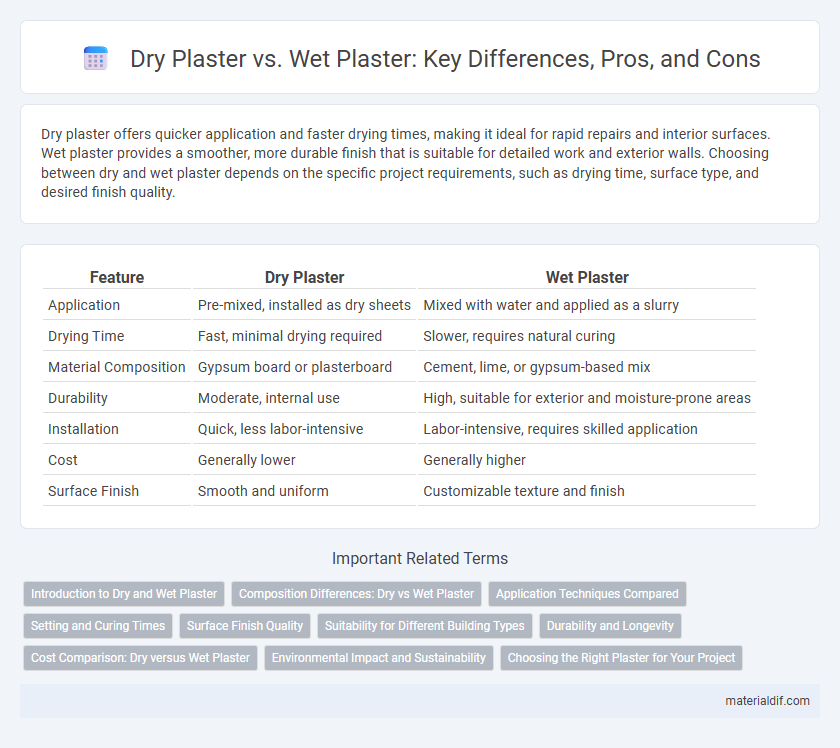

Dry plaster offers quicker application and faster drying times, making it ideal for rapid repairs and interior surfaces. Wet plaster provides a smoother, more durable finish that is suitable for detailed work and exterior walls. Choosing between dry and wet plaster depends on the specific project requirements, such as drying time, surface type, and desired finish quality.

Table of Comparison

| Feature | Dry Plaster | Wet Plaster |

|---|---|---|

| Application | Pre-mixed, installed as dry sheets | Mixed with water and applied as a slurry |

| Drying Time | Fast, minimal drying required | Slower, requires natural curing |

| Material Composition | Gypsum board or plasterboard | Cement, lime, or gypsum-based mix |

| Durability | Moderate, internal use | High, suitable for exterior and moisture-prone areas |

| Installation | Quick, less labor-intensive | Labor-intensive, requires skilled application |

| Cost | Generally lower | Generally higher |

| Surface Finish | Smooth and uniform | Customizable texture and finish |

Introduction to Dry and Wet Plaster

Dry plaster consists of pre-mixed materials such as gypsum or cement, packaged and ready to use by adding water on site, offering quick application and reduced labor time. Wet plaster is traditionally mixed on-site using sand, lime, cement, and water, providing better adhesion and breathability for walls but requiring more preparation and skilled workmanship. Choosing between dry and wet plaster depends on project requirements, including environmental conditions and surface type.

Composition Differences: Dry vs Wet Plaster

Dry plaster primarily consists of pre-mixed gypsum or cement-based powders combined with additives like lime and polymers, designed for quick application and minimal water usage. Wet plaster, on the other hand, features a higher water content with a blend of sand, cement, lime, and sometimes clay, resulting in a more malleable mix ideal for traditional hand-application techniques. The composition differences impact curing time, adhesion properties, and suitability for specific construction environments.

Application Techniques Compared

Dry plaster application involves using pre-mixed plaster sheets that are installed directly onto surfaces with mechanical fastening or adhesive methods, offering faster installation and reduced curing time. Wet plaster requires mixing water with plaster powder to create a workable paste applied manually with trowels, allowing for custom thickness and smooth finishes but demanding longer drying periods. Dry plaster provides consistent quality and cleaner application, while wet plaster offers greater flexibility in shaping and texturing walls.

Setting and Curing Times

Dry plaster typically sets faster, often within 15 to 30 minutes, allowing quicker application and initial hardening, while wet plaster requires longer setting times, ranging from several hours to a full day depending on thickness and environmental conditions. The curing process of wet plaster is more gradual, promoting better strength and durability over time due to its moisture retention during the drying phase. Dry plaster may expedite project timelines but can sometimes result in less uniform curing compared to the slower, more controlled curing characteristic of wet plaster.

Surface Finish Quality

Dry plaster offers a consistently smooth and uniform surface finish due to its controlled factory application, minimizing cracks and unevenness. Wet plaster, applied on-site, can result in variable surface textures influenced by workmanship, drying conditions, and substrate moisture content. The enhanced surface quality of dry plaster reduces the need for extensive sanding or rework, improving overall finish durability and aesthetic appeal.

Suitability for Different Building Types

Dry plaster is highly suitable for residential buildings and structures with low moisture exposure due to its quick application and reduced drying time, making it ideal for interior walls. Wet plaster is preferred for commercial and heritage buildings requiring superior durability and moisture resistance, as it creates a more robust and long-lasting finish. Choice between dry and wet plaster depends on building type, environmental conditions, and desired finish quality.

Durability and Longevity

Dry plaster offers enhanced durability due to its pre-mixed consistency, which reduces the risk of cracking and shrinkage over time. Wet plaster requires careful mixing and application, as improper techniques can lead to weakened structural integrity and reduced longevity. Overall, dry plaster provides a more consistent quality that extends the lifespan of walls and surfaces compared to traditional wet plaster methods.

Cost Comparison: Dry versus Wet Plaster

Dry plaster typically incurs higher initial costs due to pre-mixed materials and packaging, while wet plaster offers a more economical option with bulk raw materials and on-site mixing. Labor expenses differ, as dry plaster requires less application time and cleanup, potentially reducing labor costs compared to the longer setting times and preparation needed for wet plaster. Total project costs must consider material price, labor intensity, and waste management, with dry plaster favored in faster, smaller jobs and wet plaster advantageous for large-scale applications requiring extensive coverage.

Environmental Impact and Sustainability

Dry plaster offers a more sustainable option compared to wet plaster by minimizing water usage and reducing carbon emissions associated with transportation and curing processes. Its production involves fewer raw materials and generates less waste, contributing to lower environmental footprints in construction projects. Wet plaster, while traditional, often requires more energy-intensive processes and produces higher levels of runoff and waste, increasing its ecological impact.

Choosing the Right Plaster for Your Project

Dry plaster offers quick application and minimal mess, making it ideal for small repairs and interior walls where time efficiency is crucial. Wet plaster provides a smoother, more durable finish suitable for exterior surfaces and detailed architectural work, ensuring long-lasting protection against weather elements. Consider project scope, drying time, surface type, and desired finish quality when choosing between dry and wet plaster for optimal results.

Dry Plaster vs Wet Plaster Infographic

materialdif.com

materialdif.com