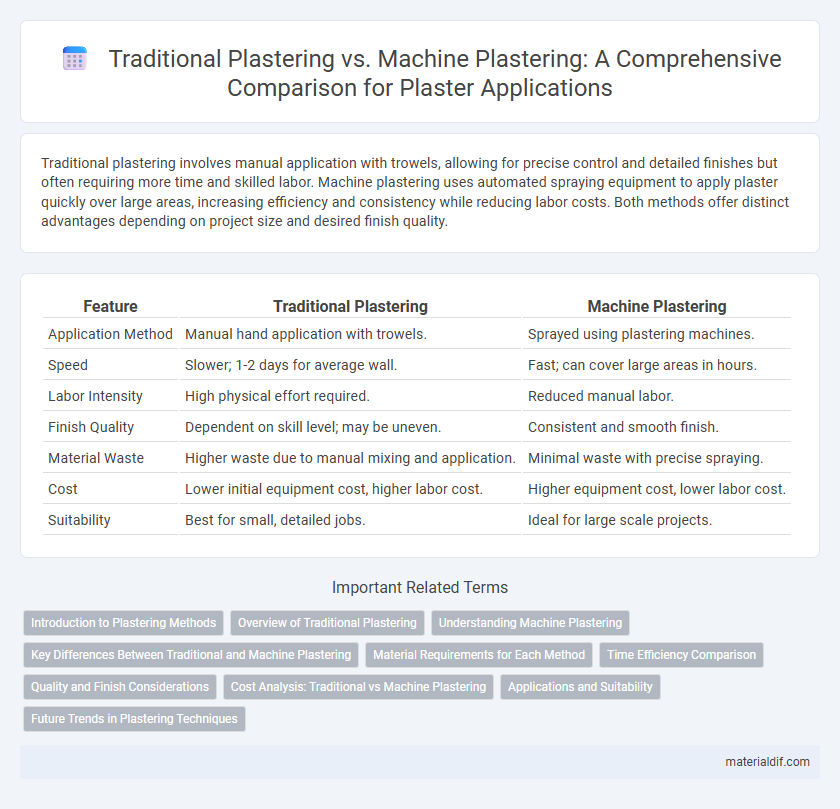

Traditional plastering involves manual application with trowels, allowing for precise control and detailed finishes but often requiring more time and skilled labor. Machine plastering uses automated spraying equipment to apply plaster quickly over large areas, increasing efficiency and consistency while reducing labor costs. Both methods offer distinct advantages depending on project size and desired finish quality.

Table of Comparison

| Feature | Traditional Plastering | Machine Plastering |

|---|---|---|

| Application Method | Manual hand application with trowels. | Sprayed using plastering machines. |

| Speed | Slower; 1-2 days for average wall. | Fast; can cover large areas in hours. |

| Labor Intensity | High physical effort required. | Reduced manual labor. |

| Finish Quality | Dependent on skill level; may be uneven. | Consistent and smooth finish. |

| Material Waste | Higher waste due to manual mixing and application. | Minimal waste with precise spraying. |

| Cost | Lower initial equipment cost, higher labor cost. | Higher equipment cost, lower labor cost. |

| Suitability | Best for small, detailed jobs. | Ideal for large scale projects. |

Introduction to Plastering Methods

Traditional plastering involves manually applying plaster with trowels, ensuring detailed craftsmanship and precise control over texture and finish. Machine plastering utilizes advanced equipment to spray plaster onto surfaces, significantly increasing speed and consistency in large-scale projects. Both methods require skilled labor but differ in application efficiency and suitability depending on project scope and architectural requirements.

Overview of Traditional Plastering

Traditional plastering involves manual application of plaster using basic tools like trowels and hawks, ensuring a smooth and uniform surface. Skilled craftsmen layer plaster in multiple coats, allowing drying time between each to achieve durability and aesthetic quality. This method is labor-intensive but offers greater control over texture and finish compared to machine plastering.

Understanding Machine Plastering

Machine plastering utilizes advanced equipment to apply plaster quickly and uniformly, significantly reducing labor time compared to traditional methods. This technique achieves consistent thickness and smooth finishes by spraying a premixed plaster blend, enhancing productivity and minimizing material waste. Understanding machine plastering involves recognizing its efficiency benefits, suitability for large-scale projects, and the importance of skilled operators to ensure quality application and surface durability.

Key Differences Between Traditional and Machine Plastering

Traditional plastering relies on manual application using trowels, resulting in a smoother finish and greater precision, while machine plastering uses automated spray machines to apply plaster quickly over large surfaces. Machine plastering significantly reduces labor time and increases consistency, making it ideal for large-scale projects, whereas traditional methods allow more control for detailed architectural elements. Cost-effectiveness and efficiency are primary advantages of machine plastering, contrasted by the artisanal quality and customization typical of traditional plastering.

Material Requirements for Each Method

Traditional plastering requires a precise mix of sand, cement, lime, and water, often in small batches to ensure quality and consistency. Machine plastering utilizes pre-mixed plaster materials, typically gypsum-based or cementitious, designed for compatibility with spray equipment, reducing material waste. The water-to-plaster ratio and aggregate size differ significantly between methods, impacting drying time and finish quality.

Time Efficiency Comparison

Traditional plastering requires skilled labor and can take several days to complete due to manual application and drying times. Machine plastering significantly reduces application time by spraying plaster directly onto surfaces, often cutting the process by half or more. Projects using machine plastering benefit from faster turnaround, enabling quicker progress and reduced labor costs.

Quality and Finish Considerations

Traditional plastering offers superior control over texture and finish, allowing skilled artisans to create intricate details and smooth surfaces that enhance aesthetic appeal. Machine plastering provides consistent application and faster completion times but may result in less precise finishes with potential for surface imperfections. Quality outcomes depend on project requirements, with traditional plastering favored for bespoke or high-end interiors and machine plastering suited for large-scale, uniform wall systems.

Cost Analysis: Traditional vs Machine Plastering

Traditional plastering typically involves higher labor costs due to manual application techniques, which can extend project timelines and increase overall expenses. Machine plastering reduces labor intensity by streamlining the application process, resulting in faster completion and lower labor costs, although initial equipment investment may be significant. Evaluating total costs depends on project size, with machine plastering offering cost efficiency for large-scale jobs, while traditional methods might suit smaller, more detailed work.

Applications and Suitability

Traditional plastering suits small-scale projects and intricate detailing due to its manual application, making it ideal for restoration and decorative work. Machine plastering offers efficiency and consistency in large-scale commercial buildings and new constructions, reducing labor time significantly. Selecting between traditional and machine plastering depends on project size, surface complexity, and desired finish quality.

Future Trends in Plastering Techniques

Future trends in plastering techniques emphasize increased adoption of machine plastering due to its efficiency, precision, and reduced labor costs, especially in large-scale construction projects. Traditional plastering remains valued for its artisanal quality and adaptability in restoration works but faces challenges in meeting the demands of faster project timelines. Innovations in automated plastering technologies, such as robotic sprayers and AI-controlled application systems, are poised to revolutionize wall finishing processes, enhancing consistency and minimizing material wastage.

Traditional Plastering vs Machine Plastering Infographic

materialdif.com

materialdif.com