Machine-applied plaster offers faster application and consistent thickness compared to hand-applied plaster, reducing labor costs and project timelines. Hand-applied plaster allows for greater precision and customization, making it ideal for intricate architectural details or restorations. Choosing between these methods depends on project scale, desired finish quality, and budget constraints.

Table of Comparison

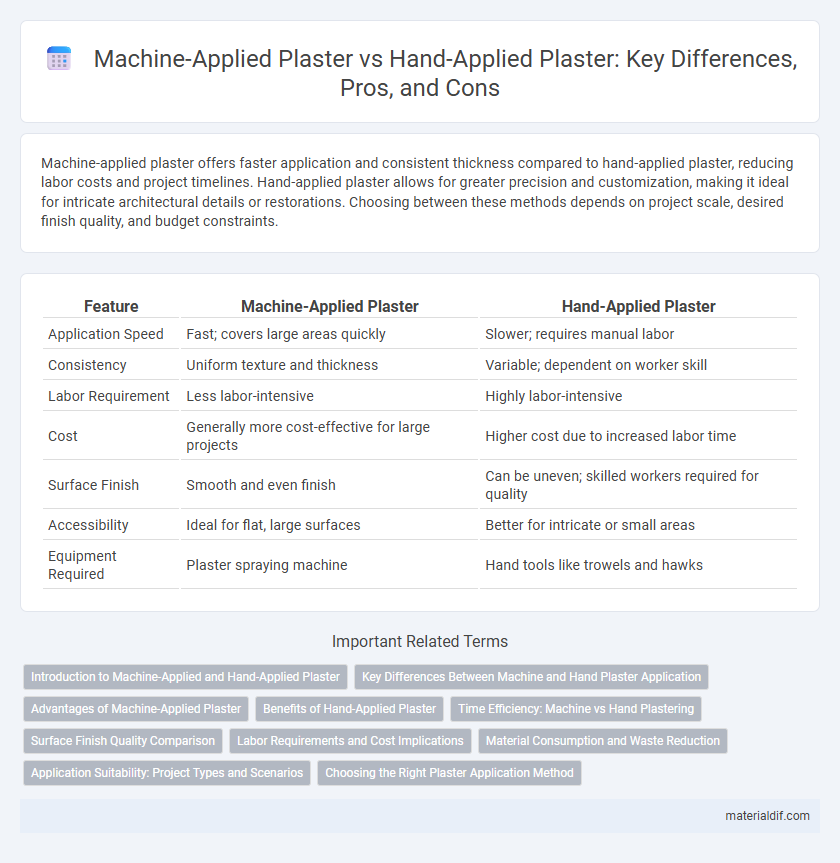

| Feature | Machine-Applied Plaster | Hand-Applied Plaster |

|---|---|---|

| Application Speed | Fast; covers large areas quickly | Slower; requires manual labor |

| Consistency | Uniform texture and thickness | Variable; dependent on worker skill |

| Labor Requirement | Less labor-intensive | Highly labor-intensive |

| Cost | Generally more cost-effective for large projects | Higher cost due to increased labor time |

| Surface Finish | Smooth and even finish | Can be uneven; skilled workers required for quality |

| Accessibility | Ideal for flat, large surfaces | Better for intricate or small areas |

| Equipment Required | Plaster spraying machine | Hand tools like trowels and hawks |

Introduction to Machine-Applied and Hand-Applied Plaster

Machine-applied plaster offers consistent application with faster coverage rates, significantly reducing labor time for large-scale projects. Hand-applied plaster provides precision and control, making it ideal for intricate details and uneven surfaces where customized finishing is essential. Understanding the distinct advantages of each method helps optimize plastering efficiency and quality based on project requirements.

Key Differences Between Machine and Hand Plaster Application

Machine-applied plaster offers faster application rates and more consistent texture compared to hand-applied plaster, making it ideal for large-scale projects requiring uniform finishes. Hand-applied plaster allows for greater precision and customization, especially on intricate surfaces or corners, but it requires more skilled labor and longer curing times. Machine application reduces labor costs and material waste, whereas hand plastering provides superior control over thickness and detail in specialized areas.

Advantages of Machine-Applied Plaster

Machine-applied plaster ensures consistent thickness and uniform texture, significantly reducing human error and labor time compared to hand-applied methods. This technique increases productivity by enabling faster surface coverage, making it ideal for large-scale construction projects. Enhanced adhesion and durability result from the even application pressure and controlled mix delivery inherent in machine technology.

Benefits of Hand-Applied Plaster

Hand-applied plaster offers superior control and precision, ensuring a smoother and more durable finish compared to machine-applied methods. Skilled artisans can address surface imperfections and intricate details more effectively, resulting in enhanced aesthetic appeal and longevity. This traditional technique also minimizes material waste and allows for customized thickness adjustments, optimizing both performance and cost-efficiency.

Time Efficiency: Machine vs Hand Plastering

Machine-applied plaster significantly reduces application time by delivering consistent layers at a faster rate compared to hand-applied plaster. Advanced plastering machines can cover large surfaces in a fraction of the time required for manual labor, enhancing productivity on construction sites. Although hand plastering allows for precise detailing, it is considerably slower, making machine application the preferred choice for time efficiency in large-scale projects.

Surface Finish Quality Comparison

Machine-applied plaster offers a more uniform and consistent surface finish due to precise control of material flow and application speed, reducing human error and inconsistencies. Hand-applied plaster can achieve finer detailing and smoother finishes in complex or intricate areas, but may vary in texture and thickness depending on the skill level of the applicator. Overall, machine application excels in large-scale projects with standardized finishes, while hand application remains preferred for quality craftsmanship in bespoke or detailed work.

Labor Requirements and Cost Implications

Machine-applied plaster significantly reduces labor requirements by automating the mixing and application processes, allowing for faster project completion and minimizing manual effort. This mechanization lowers overall labor costs compared to hand-applied plaster, which demands skilled craftsmen and more time-intensive work. Consequently, machine application offers a cost-effective solution for large-scale plastering projects without compromising quality.

Material Consumption and Waste Reduction

Machine-applied plaster significantly reduces material consumption through precise spraying technology, ensuring uniform thickness and minimizing excess usage. Hand-applied plaster often leads to higher waste due to inconsistent application and manual overuse of materials. Optimizing plaster application with machines enhances efficiency and lowers environmental impact by cutting down on surplus plaster and debris.

Application Suitability: Project Types and Scenarios

Machine-applied plaster is ideal for large-scale commercial or industrial projects requiring rapid, uniform coverage, while hand-applied plaster suits smaller, detailed residential or restoration tasks needing precise control. Machine application excels in new construction and extensive wall surfaces, providing efficiency and consistency, whereas hand application is preferred for intricate architectural features or repairs with complex textures. Selecting between these methods depends on project size, complexity, and desired finish quality.

Choosing the Right Plaster Application Method

Machine-applied plaster offers consistent thickness and faster coverage ideal for large-scale projects, while hand-applied plaster provides superior control and precision suited for intricate surfaces and repairs. Selecting the right plaster application method depends on project size, surface complexity, and desired finish quality. Evaluating labor costs, time constraints, and skill requirements ensures optimal plastering performance and durability.

Machine-Applied Plaster vs Hand-Applied Plaster Infographic

materialdif.com

materialdif.com