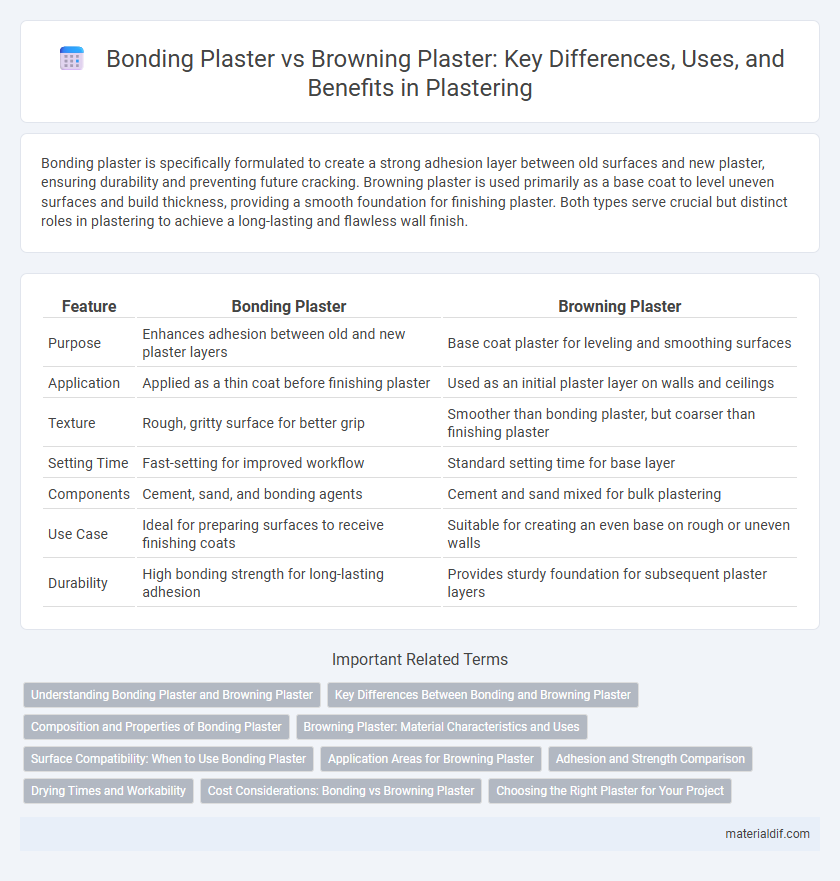

Bonding plaster is specifically formulated to create a strong adhesion layer between old surfaces and new plaster, ensuring durability and preventing future cracking. Browning plaster is used primarily as a base coat to level uneven surfaces and build thickness, providing a smooth foundation for finishing plaster. Both types serve crucial but distinct roles in plastering to achieve a long-lasting and flawless wall finish.

Table of Comparison

| Feature | Bonding Plaster | Browning Plaster |

|---|---|---|

| Purpose | Enhances adhesion between old and new plaster layers | Base coat plaster for leveling and smoothing surfaces |

| Application | Applied as a thin coat before finishing plaster | Used as an initial plaster layer on walls and ceilings |

| Texture | Rough, gritty surface for better grip | Smoother than bonding plaster, but coarser than finishing plaster |

| Setting Time | Fast-setting for improved workflow | Standard setting time for base layer |

| Components | Cement, sand, and bonding agents | Cement and sand mixed for bulk plastering |

| Use Case | Ideal for preparing surfaces to receive finishing coats | Suitable for creating an even base on rough or uneven walls |

| Durability | High bonding strength for long-lasting adhesion | Provides sturdy foundation for subsequent plaster layers |

Understanding Bonding Plaster and Browning Plaster

Bonding plaster is a specialized adhesive plaster designed to create a strong bond between base surfaces and finishing coats, enhancing durability and preventing cracks. Browning plaster, also known as undercoat plaster, provides a smooth, even surface by filling minor imperfections and leveling walls before applying the final plaster or paint. Understanding the specific purposes and compositions of bonding and browning plaster ensures optimal application and long-lasting wall finishes.

Key Differences Between Bonding and Browning Plaster

Bonding plaster is primarily designed to improve adhesion on smooth or non-porous surfaces, creating a strong base for subsequent layers, while browning plaster is used to level uneven surfaces and build thickness before applying a finishing coat. Bonding plaster typically contains additives that enhance its sticking power, whereas browning plaster has a coarser texture suitable for filling deep imperfections. The key difference lies in their application purpose: bonding plaster ensures better surface grip, and browning plaster provides structural buildup and surface regularization.

Composition and Properties of Bonding Plaster

Bonding plaster is primarily composed of gypsum, sand, and additives that enhance its adhesive qualities, making it ideal for providing a strong base coat on walls. It exhibits excellent bonding strength, quick setting time, and good workability, ensuring a durable and smooth surface suitable for finishing layers. Unlike browning plaster, which contains clay and is used mainly for surface levelling, bonding plaster's formulation is optimized for robust adhesion to various substrates.

Browning Plaster: Material Characteristics and Uses

Browning plaster is a fine-textured, reddish-brown plaster known for its excellent adhesion and durability on masonry surfaces. It consists primarily of clay, sand, and iron oxide pigments, providing both aesthetic appeal and protective qualities. Commonly used for exterior wall finishes, browning plaster resists weathering and enhances structural longevity.

Surface Compatibility: When to Use Bonding Plaster

Bonding plaster is specially formulated for application on smooth, non-porous surfaces such as painted walls, tiles, or concrete, where strong adhesion is essential. Unlike browning plaster, which is suited for rougher, more absorbent surfaces like brick or blockwork, bonding plaster ensures a secure and long-lasting finish on challenging substrates. This makes bonding plaster ideal for renovation projects requiring a reliable base coat over sealed or previously decorated surfaces.

Application Areas for Browning Plaster

Browning plaster is primarily used in decorative arts and restoration projects to create detailed architectural moldings and ornamental features due to its fine texture and smooth finish. It is ideal for indoor applications, including ceiling roses, cornices, and intricate wall decorations, where aesthetic appeal is essential. Unlike bonding plaster, which is formulated for initial coats and adhesion to rough surfaces, browning plaster excels in providing a refined surface for painting and finishing.

Adhesion and Strength Comparison

Bonding plaster exhibits superior adhesion and enhanced compressive strength compared to browning plaster, making it ideal for ensuring durable wall finishes on various substrates. Browning plaster, while offering faster drying times, typically has lower bonding capacity, which can lead to weaker structural integrity in multilayer applications. Choosing bonding plaster improves overall surface cohesion and longevity, especially in high-stress or moisture-prone environments.

Drying Times and Workability

Bonding plaster typically dries faster than browning plaster due to its finer composition, allowing quicker setting times ideal for rapid project completion. Browning plaster offers superior workability with a creamier texture, making it easier to apply and shape but generally requires longer drying periods, often up to 48 hours. Choosing between the two depends on the balance needed between speedy drying and ease of application in construction or renovation tasks.

Cost Considerations: Bonding vs Browning Plaster

Bonding plaster typically incurs higher costs due to its superior adhesive properties and faster setting times, which reduce labor expenses despite pricier materials. Browning plaster is more economical upfront, favored for its ease of application and suitability for base coats, though it may require additional layers or longer curing periods that increase total project costs. Evaluating project scope and finish requirements helps determine the most cost-effective plaster choice between bonding and browning options.

Choosing the Right Plaster for Your Project

Bonding plaster provides a strong adhesive base ideal for rough or uneven surfaces, ensuring excellent grip and durability in construction projects. Browning plaster is preferred for finishing work, offering a smooth and fine surface suitable for painting or wallpapering. Selecting the right plaster depends on the substrate condition and desired finish quality to achieve optimal results.

Bonding Plaster vs Browning Plaster Infographic

materialdif.com

materialdif.com