Dry plaster mix consists of pre-measured powder ingredients that require water addition before application, allowing for precise control over consistency and workability. Wet plaster mix is already blended with water, offering immediate usability but limited working time and less flexibility in adjusting thickness or texture. Choosing between dry and wet plaster mix depends on project requirements, with dry mix providing extended shelf life and adaptability, while wet mix is convenient for quick, small-scale repairs.

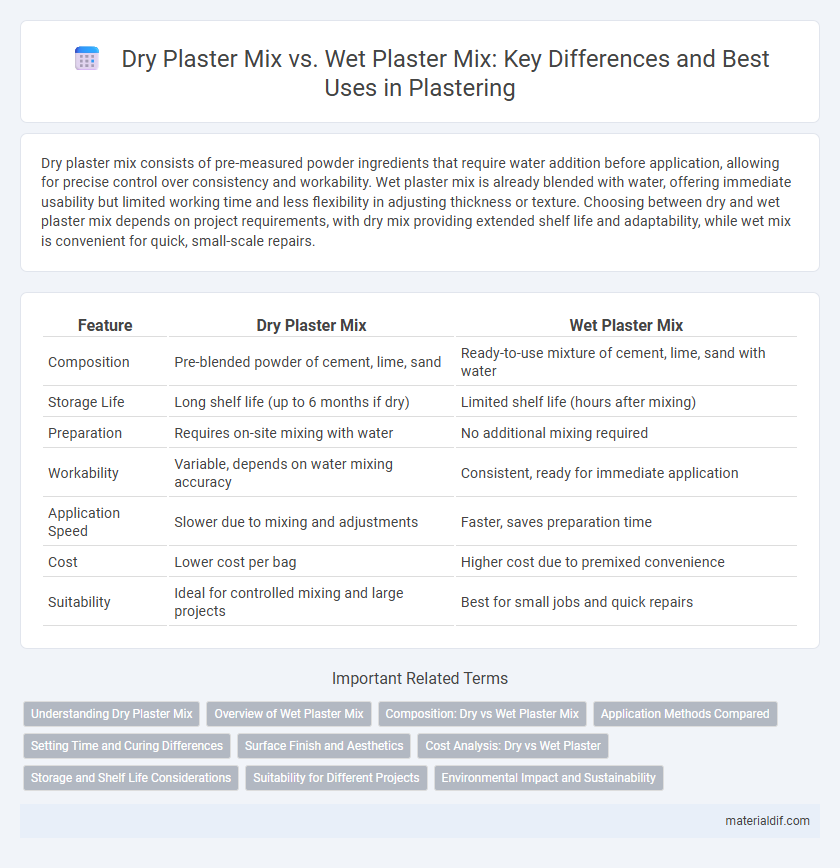

Table of Comparison

| Feature | Dry Plaster Mix | Wet Plaster Mix |

|---|---|---|

| Composition | Pre-blended powder of cement, lime, sand | Ready-to-use mixture of cement, lime, sand with water |

| Storage Life | Long shelf life (up to 6 months if dry) | Limited shelf life (hours after mixing) |

| Preparation | Requires on-site mixing with water | No additional mixing required |

| Workability | Variable, depends on water mixing accuracy | Consistent, ready for immediate application |

| Application Speed | Slower due to mixing and adjustments | Faster, saves preparation time |

| Cost | Lower cost per bag | Higher cost due to premixed convenience |

| Suitability | Ideal for controlled mixing and large projects | Best for small jobs and quick repairs |

Understanding Dry Plaster Mix

Dry plaster mix consists of pre-measured, powdered ingredients like cement, lime, sand, and additives, designed for on-site mixing with water to achieve the desired consistency. This allows precise control over the plaster's workability, setting time, and strength, making it ideal for varying environmental conditions and project requirements. Understanding the properties of dry plaster mix ensures optimal application and durability compared to pre-mixed wet plaster.

Overview of Wet Plaster Mix

Wet plaster mix consists of pre-blended materials combined with water to create a ready-to-apply paste, enabling smooth and consistent application on walls and ceilings. This type of mix allows better adhesion and curing, making it ideal for detailed finishes and reducing the likelihood of cracks compared to dry mix. Wet plaster's formulation often includes cement, sand, lime, and additives optimized for workability and durability in various construction environments.

Composition: Dry vs Wet Plaster Mix

Dry plaster mix typically consists of a pre-measured combination of cement, sand, and additives in powder form, ensuring consistency and ease of storage. Wet plaster mix involves adding water to the dry components just before application, which activates the chemical reactions necessary for setting and hardening. The ratio of water to dry mix is critical in wet plaster, affecting workability, drying time, and final strength.

Application Methods Compared

Dry plaster mix offers greater control over consistency and thickness during application, allowing for customized texture and faster setting times. Wet plaster mix, pre-mixed with water, provides ease of use and smoother application but limits adjustments once applied. Professionals often choose dry mix for complex surfaces requiring precise layering, while wet mix suits straightforward, rapid coverage tasks.

Setting Time and Curing Differences

Dry plaster mix typically requires the addition of water before application, allowing for flexible adjustment of consistency and immediate use, with a faster initial setting time ranging from 20 to 40 minutes. Wet plaster mix comes pre-mixed with water, offering more consistent moisture content but generally exhibits longer setting times of 1 to 2 hours, which impacts the overall curing duration. The curing process for dry plaster is often faster and more controlled, whereas wet plaster requires extended drying times to achieve full hardness and durability.

Surface Finish and Aesthetics

Dry plaster mix offers greater control over consistency, allowing for a smoother, more uniform surface finish ideal for detailed aesthetic work. Wet plaster mix, while easier to apply, can result in a less consistent texture, often requiring additional sanding or smoothing to achieve a polished look. The choice between dry and wet plaster mix significantly impacts the final surface aesthetics, with dry mixes preferred for high-quality, fine finishes.

Cost Analysis: Dry vs Wet Plaster

Dry plaster mix typically incurs higher initial costs due to packaging and transportation expenses but reduces wastage and storage requirements on-site, leading to potential cost savings in large projects. Wet plaster mix often comes at a lower upfront price but demands immediate usage and proper storage to avoid spoilage, potentially increasing overall project costs due to material loss. Evaluating labor costs, material shelf life, and waste management is critical when conducting a cost analysis between dry and wet plaster mixes.

Storage and Shelf Life Considerations

Dry plaster mix offers extended shelf life when stored in airtight, moisture-free conditions, typically lasting up to 12 months. Wet plaster mix requires immediate use due to its limited usability, generally remaining effective for only a few hours before hardening. Proper storage of dry mix reduces waste and ensures consistent plaster quality for future applications.

Suitability for Different Projects

Dry plaster mix is ideal for small repairs and patching since it allows precise control over water addition, ensuring a consistent texture suited for detailed finishing. Wet plaster mix is better suited for large-scale projects like wall rendering and ceilings, providing a ready-to-use solution that accelerates application and saves labor time. Contractors prefer dry mix for custom thickness and strength modifications, while wet mix is favored for rapid, uniform coverage on extensive surfaces.

Environmental Impact and Sustainability

Dry plaster mix significantly reduces environmental impact by minimizing water usage and lowering transportation emissions due to its lightweight, concentrated form. Wet plaster mix often involves higher energy consumption during production and increased waste from unused material, contributing to greater landfill volume. Selecting dry plaster mix supports sustainable construction practices through improved resource efficiency and decreased carbon footprint.

Dry plaster mix vs Wet plaster mix Infographic

materialdif.com

materialdif.com