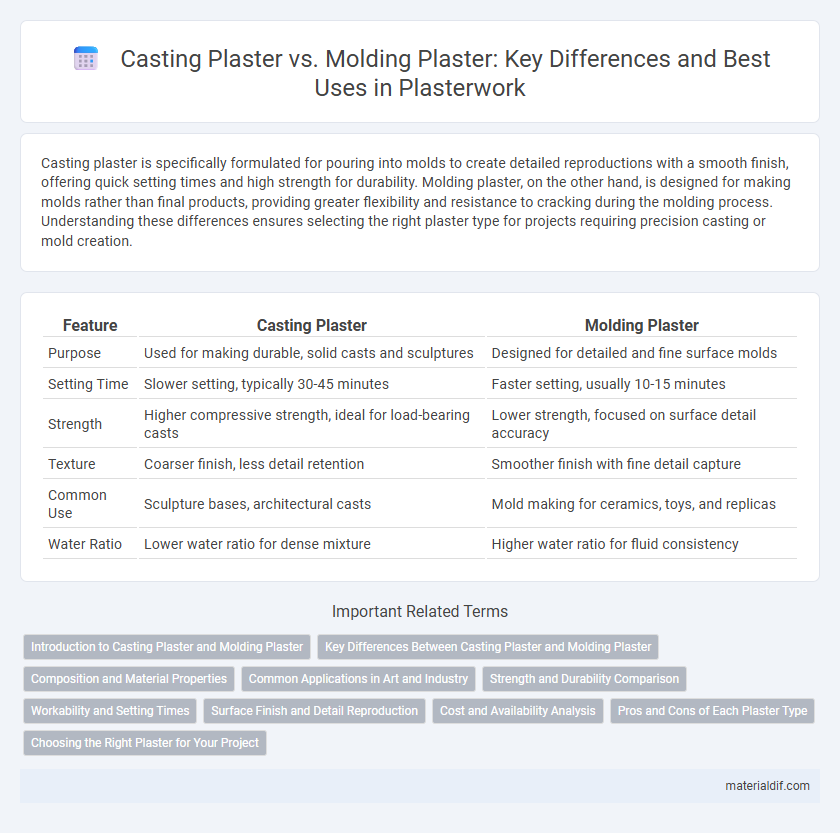

Casting plaster is specifically formulated for pouring into molds to create detailed reproductions with a smooth finish, offering quick setting times and high strength for durability. Molding plaster, on the other hand, is designed for making molds rather than final products, providing greater flexibility and resistance to cracking during the molding process. Understanding these differences ensures selecting the right plaster type for projects requiring precision casting or mold creation.

Table of Comparison

| Feature | Casting Plaster | Molding Plaster |

|---|---|---|

| Purpose | Used for making durable, solid casts and sculptures | Designed for detailed and fine surface molds |

| Setting Time | Slower setting, typically 30-45 minutes | Faster setting, usually 10-15 minutes |

| Strength | Higher compressive strength, ideal for load-bearing casts | Lower strength, focused on surface detail accuracy |

| Texture | Coarser finish, less detail retention | Smoother finish with fine detail capture |

| Common Use | Sculpture bases, architectural casts | Mold making for ceramics, toys, and replicas |

| Water Ratio | Lower water ratio for dense mixture | Higher water ratio for fluid consistency |

Introduction to Casting Plaster and Molding Plaster

Casting plaster, a fine, white powder primarily composed of calcium sulfate hemihydrate, is prized for its fluidity and ability to capture intricate details, making it ideal for creating precise replicas and molds. Molding plaster, meanwhile, is formulated to be harder and more durable, designed to withstand repeated use in mold-making applications without losing its shape or strength. Both types serve distinct purposes in art and construction, with casting plaster favored for one-time detailed casts and molding plaster chosen for resilient, reusable molds.

Key Differences Between Casting Plaster and Molding Plaster

Casting plaster features a finer particle size and lower density, making it ideal for creating detailed, thin-walled objects with smooth finishes. Molding plaster possesses a higher density and coarser texture, providing enhanced strength and durability for robust molds and models. The key differences lie in their particle size, density, setting time, and intended use, with casting plaster suited for precision and molding plaster for structural integrity.

Composition and Material Properties

Casting plaster typically contains a higher concentration of calcined gypsum, resulting in a finer grain and faster setting time, ideal for detailed mold replication. Molding plaster, often blended with additives like accelerators or retarders, offers improved flexibility and reduced brittleness for complex shapes. The distinct composition differences affect durability, surface finish, and application suitability in various plaster casting projects.

Common Applications in Art and Industry

Casting plaster is widely used for creating detailed sculptures, architectural molds, and decorative objects due to its fine texture and smooth finish. Molding plaster, preferred in industrial settings, excels in producing durable molds for ceramics, dental impressions, and prototype patterns because of its higher strength and faster setting time. Artists and manufacturers select casting plaster for intricate artistic expressions, while molding plaster serves functional purposes requiring longevity and precision.

Strength and Durability Comparison

Casting plaster typically offers higher strength and durability compared to molding plaster due to its denser composition and lower porosity. Molding plaster, designed for fine detail replication, is softer and more brittle, making it less suitable for structural or load-bearing applications. When selecting plaster for projects requiring longevity and impact resistance, casting plaster is the preferable option.

Workability and Setting Times

Casting plaster exhibits a finer particle size, resulting in a smoother texture and extended workability time compared to molding plaster. Molding plaster sets rapidly, often within 5 to 10 minutes, making it ideal for quick impressions but limiting detailed work. In contrast, casting plaster allows for longer manipulation, with setting times typically ranging from 20 to 30 minutes, enhancing precision in complex molds.

Surface Finish and Detail Reproduction

Casting plaster offers a smoother surface finish ideal for fine detail reproduction, making it preferred for precise sculpting and mold-making tasks. Molding plaster tends to have a coarser texture, which may slightly reduce clarity in intricate details but provides better strength for repeated use. Selecting between casting and molding plaster depends on the required balance between surface smoothness and durability for specific artistic or industrial applications.

Cost and Availability Analysis

Casting plaster typically offers a more affordable option compared to molding plaster, making it a preferred choice for large-scale projects and artists with budget constraints. Availability-wise, casting plaster is widely accessible in general hardware stores and art supply outlets, whereas molding plaster can be more specialized, found primarily through specialized suppliers or online retailers. The cost difference largely stems from variations in purity and setting properties, with molding plaster often commanding a higher price due to its finer grain and smoother finish tailored for detailed mold making.

Pros and Cons of Each Plaster Type

Casting plaster offers high strength and durability, making it ideal for detailed sculptures and long-lasting casts, but it requires careful mixing to avoid brittleness and is prone to cracking if not properly cured. Molding plaster provides excellent surface detail and faster setting times, suitable for replicating intricate textures in molds, yet it tends to be softer and less durable, limiting its use for heavy or load-bearing applications. Choosing between casting plaster and molding plaster depends on the project's need for strength versus fine detail and the working time available for setting and curing.

Choosing the Right Plaster for Your Project

Casting plaster and molding plaster each serve distinct purposes in construction and art projects, with casting plaster favored for quick-setting applications and creating detailed, smooth finishes. Molding plaster offers superior strength and durability, making it ideal for molds requiring repeated use or more intricate designs. Selecting the right plaster depends on project requirements such as drying time, surface detail, and structural stability to ensure optimal results.

Casting Plaster vs Molding Plaster Infographic

materialdif.com

materialdif.com