Orthopedic plaster is specifically formulated for medical use, offering lightweight, quick-setting properties that provide strong support and immobilization for broken bones and fractures. Building plaster, on the other hand, is designed for construction purposes, including wall finishing and molding, featuring coarser texture and slower drying times to ensure durability and easy application on various surfaces. Understanding the distinct formulations and applications of orthopedic versus building plaster is essential for selecting the appropriate material based on structural or medical requirements.

Table of Comparison

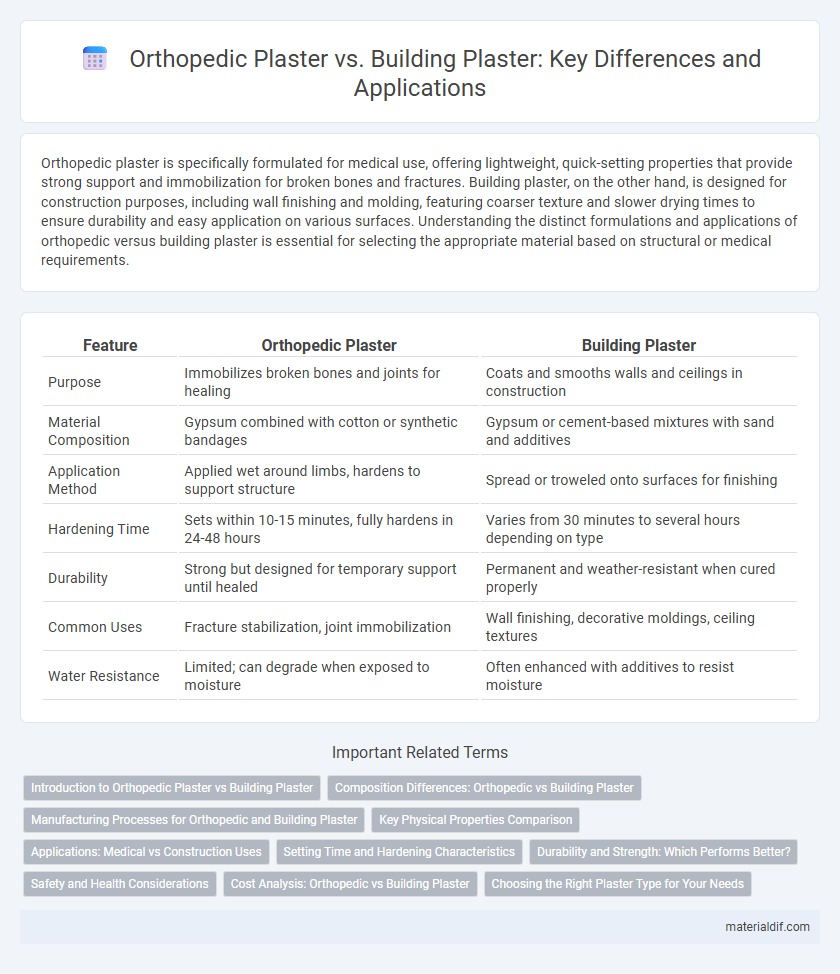

| Feature | Orthopedic Plaster | Building Plaster |

|---|---|---|

| Purpose | Immobilizes broken bones and joints for healing | Coats and smooths walls and ceilings in construction |

| Material Composition | Gypsum combined with cotton or synthetic bandages | Gypsum or cement-based mixtures with sand and additives |

| Application Method | Applied wet around limbs, hardens to support structure | Spread or troweled onto surfaces for finishing |

| Hardening Time | Sets within 10-15 minutes, fully hardens in 24-48 hours | Varies from 30 minutes to several hours depending on type |

| Durability | Strong but designed for temporary support until healed | Permanent and weather-resistant when cured properly |

| Common Uses | Fracture stabilization, joint immobilization | Wall finishing, decorative moldings, ceiling textures |

| Water Resistance | Limited; can degrade when exposed to moisture | Often enhanced with additives to resist moisture |

Introduction to Orthopedic Plaster vs Building Plaster

Orthopedic plaster, primarily composed of plaster of Paris, is specially formulated for medical use to immobilize broken bones and support healing by hardening quickly upon application. Building plaster, made from gypsum or lime, serves as a construction material used for coating walls and ceilings, providing a smooth, durable finish. The key difference lies in their composition and purpose: orthopedic plaster prioritizes biocompatibility and setting speed for patient safety, while building plaster focuses on structural integrity and aesthetic enhancement in architectural projects.

Composition Differences: Orthopedic vs Building Plaster

Orthopedic plaster is primarily composed of calcium sulfate hemihydrate, which hardens quickly upon mixing with water to create a strong, lightweight cast ideal for immobilizing fractures. Building plaster, or gypsum plaster, contains a higher proportion of additives such as lime, sand, or cement to enhance durability, texture, and adhesion for construction purposes. The distinct composition differences directly influence their respective setting times, strength, and application suitability in medical versus construction fields.

Manufacturing Processes for Orthopedic and Building Plaster

Orthopedic plaster is manufactured using high-purity gypsum that undergoes calcination at controlled temperatures to achieve fine particle size and fast-setting properties, ensuring biocompatibility and optimal molding for immobilization. Building plaster is produced by heating raw gypsum to remove moisture, resulting in a coarse powder with slower setting times and enhanced strength for construction applications. The distinct calcination methods and particle treatments in manufacturing directly influence the physical characteristics and end-use suitability of orthopedic and building plasters.

Key Physical Properties Comparison

Orthopedic plaster primarily features high tensile strength, rapid setting time, and excellent moldability to conform precisely to body contours, ensuring effective immobilization during healing. Building plaster, in contrast, emphasizes durability, fire resistance, and smooth finish, with moderate setting time to enhance surface workability in construction. The density and porosity of orthopedic plaster are optimized for lightweight comfort, whereas building plaster prioritizes structural integrity and adhesion to various substrates.

Applications: Medical vs Construction Uses

Orthopedic plaster, primarily composed of gypsum, is designed for medical use to immobilize fractures and support healing by providing a rigid yet lightweight cast. Building plaster, often containing lime or cement, is utilized in construction for wall coating, surface smoothing, and decorative finishes, offering durability and fire resistance. Each type serves distinct applications reflecting their material properties, with orthopedic plaster optimized for patient care and building plaster engineered for architectural functionality.

Setting Time and Hardening Characteristics

Orthopedic plaster typically sets within 5 to 7 minutes, offering rapid hardening essential for immobilizing fractures, while building plaster has a longer setting time, usually around 20 to 30 minutes, to allow for smooth application and finishing. The hardening characteristics of orthopedic plaster involve a quick exothermic reaction that creates a strong, rigid cast, whereas building plaster hardens more gradually to form a durable yet workable surface. These differences in setting and hardening optimize orthopedic plaster for medical use and building plaster for construction and decorative purposes.

Durability and Strength: Which Performs Better?

Orthopedic plaster, composed primarily of gypsum and designed for medical use, offers moderate strength with a focus on quick setting and moldability to support bone healing. Building plaster, often formulated with additives like lime or cement, provides superior durability and structural strength suitable for construction and surface finishing. In terms of performance, building plaster exceeds orthopedic plaster in long-term strength and resistance to environmental factors.

Safety and Health Considerations

Orthopedic plaster, made from medical-grade gypsum, is designed for safe skin contact and controlled setting times to minimize heat-related burns during application, ensuring patient safety and comfort. In contrast, building plaster contains additives and chemicals that can release harmful dust and fumes, posing respiratory hazards and skin irritation risks during construction use. Proper ventilation, protective gear, and handling protocols are critical to safely managing building plaster exposure.

Cost Analysis: Orthopedic vs Building Plaster

Orthopedic plaster, primarily composed of gypsum and bandages, typically incurs higher costs due to specialized materials and medical-grade manufacturing standards. Building plaster, made from materials like lime, cement, or synthetic gypsum, offers a more cost-effective option for construction purposes but lacks the precision and durability required for medical applications. Cost analysis reveals orthopedic plaster expenses are justified by its specific biomedical efficacy, whereas building plaster prioritizes affordability and volume for structural use.

Choosing the Right Plaster Type for Your Needs

Orthopedic plaster, composed primarily of gypsum and designed for medical applications, offers rapid setting and strong immobilization for fractures and casts. Building plaster, typically made from hydrated lime or cement, is formulated for construction purposes, providing smooth wall finishes and durability. Selecting the correct plaster type depends on the intended use--opt for orthopedic plaster for medical immobilization and building plaster for structural or decorative wall applications.

Orthopedic Plaster vs Building Plaster Infographic

materialdif.com

materialdif.com