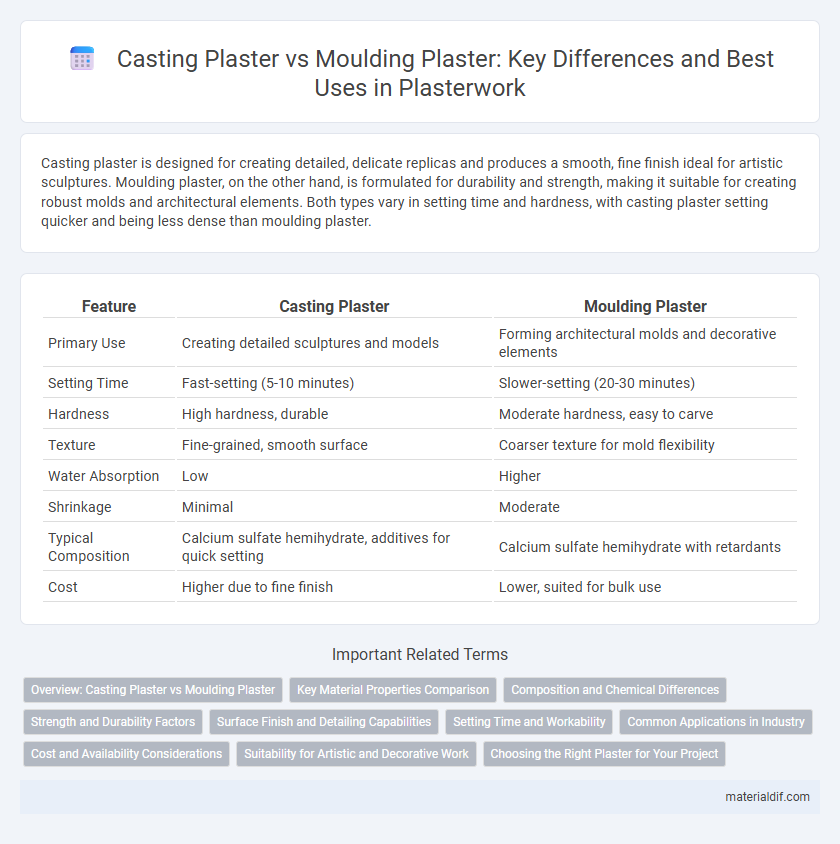

Casting plaster is designed for creating detailed, delicate replicas and produces a smooth, fine finish ideal for artistic sculptures. Moulding plaster, on the other hand, is formulated for durability and strength, making it suitable for creating robust molds and architectural elements. Both types vary in setting time and hardness, with casting plaster setting quicker and being less dense than moulding plaster.

Table of Comparison

| Feature | Casting Plaster | Moulding Plaster |

|---|---|---|

| Primary Use | Creating detailed sculptures and models | Forming architectural molds and decorative elements |

| Setting Time | Fast-setting (5-10 minutes) | Slower-setting (20-30 minutes) |

| Hardness | High hardness, durable | Moderate hardness, easy to carve |

| Texture | Fine-grained, smooth surface | Coarser texture for mold flexibility |

| Water Absorption | Low | Higher |

| Shrinkage | Minimal | Moderate |

| Typical Composition | Calcium sulfate hemihydrate, additives for quick setting | Calcium sulfate hemihydrate with retardants |

| Cost | Higher due to fine finish | Lower, suited for bulk use |

Overview: Casting Plaster vs Moulding Plaster

Casting plaster is formulated with finer particles, allowing it to flow smoothly into intricate molds for producing detailed sculptures or architectural elements. Moulding plaster has a coarser texture and is designed for creating strong, durable molds and models used in construction and decorative arts. Both types offer specific setting times and strengths optimized for their applications, with casting plaster typically setting faster and providing a smoother finish.

Key Material Properties Comparison

Casting plaster typically has a finer particle size and lower water absorption rate, resulting in a smoother finish and higher detail reproduction, whereas moulding plaster offers greater plasticity and flexibility for shaping complex forms. The setting time of casting plaster is generally faster, providing quicker demolding, while moulding plaster exhibits enhanced tensile strength and durability suited for repeated use. Both types vary in density, with casting plaster being denser for precision work, and moulding plaster lighter to facilitate easier manipulation and removal from molds.

Composition and Chemical Differences

Casting plaster typically consists of hemihydrate calcium sulfate derived from natural gypsum, offering fine particle size and rapid setting properties ideal for detailed molds. Moulding plaster contains a coarser form of calcium sulfate hemihydrate with added retardants or fillers to enhance workability and prevent shrinkage during mold fabrication. The chemical distinction lies in the purity and particle size of the calcium sulfate, affecting setting time, strength, and surface finish between casting and moulding applications.

Strength and Durability Factors

Casting plaster typically exhibits lower strength and durability compared to moulding plaster, making it more suitable for delicate or temporary forms. Moulding plaster contains additives that enhance its toughness and resistance to cracking, ensuring long-lasting and robust finished products. Strength factors such as compressive strength and abrasion resistance are significantly higher in moulding plaster, supporting its use in detailed, reusable moulds.

Surface Finish and Detailing Capabilities

Casting plaster offers a smoother surface finish ideal for fine detail reproduction, making it suitable for intricate sculptures and molds. Moulding plaster provides a slightly coarser texture but excels in durability and strength, accommodating larger forms and repetitive casting. The choice depends on the required level of detail and surface smoothness for the final product.

Setting Time and Workability

Casting plaster typically has a faster setting time ranging from 5 to 15 minutes, making it ideal for quick mold production, whereas moulding plaster usually sets more slowly, around 20 to 30 minutes, allowing extended workability for intricate details. Workability of casting plaster is limited due to rapid hardening, which demands swift application, while moulding plaster offers greater flexibility and longer working time suited for detailed sculpting and complex molds. The difference in setting kinetics and workability between these plasters directly influences their suitability for distinct artistic and industrial applications.

Common Applications in Industry

Casting plaster is commonly used in the production of detailed sculptures, dental molds, and ceramic prototypes due to its finer texture and ability to capture intricate details. Moulding plaster, known for its rapid setting time and durability, is preferred in architectural mold making, decorative elements, and repair works where strength and quick turnaround are essential. Both types serve critical roles across industries such as art restoration, dentistry, and construction, tailored to specific application needs based on their physical properties.

Cost and Availability Considerations

Casting plaster typically costs less and is widely available at most art supply stores and building material outlets, making it a budget-friendly choice for large projects. Moulding plaster tends to be pricier due to its finer texture and specialized formulation, and it is often found in specialty shops or ordered online. The cost and availability differences influence their suitability, with casting plaster favored for bulk applications and moulding plaster preferred for detailed artistic work.

Suitability for Artistic and Decorative Work

Casting plaster is ideal for creating detailed artistic sculptures due to its fine texture and smooth finish, which captures intricate details effectively. Moulding plaster offers greater durability and strength, making it suitable for decorative architectural elements that require robustness and longevity. The choice between casting and moulding plaster depends on the balance between detail precision and structural resilience needed for the specific artistic or decorative project.

Choosing the Right Plaster for Your Project

Casting plaster offers a quicker setting time and higher strength, making it ideal for detailed sculptures and decorative items requiring durability. Moulding plaster, with its finer texture and slower setting, is suited for intricate moulds and precision work where surface finish is critical. Selecting the right plaster depends on project requirements such as drying time, detail level, and final application durability.

Casting plaster vs Moulding plaster Infographic

materialdif.com

materialdif.com