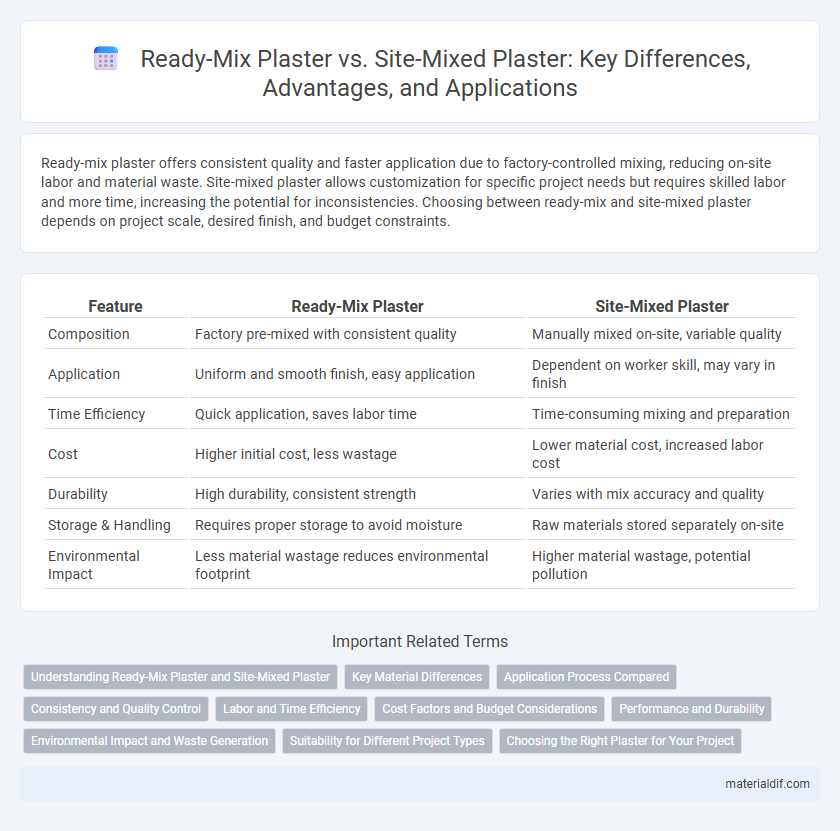

Ready-mix plaster offers consistent quality and faster application due to factory-controlled mixing, reducing on-site labor and material waste. Site-mixed plaster allows customization for specific project needs but requires skilled labor and more time, increasing the potential for inconsistencies. Choosing between ready-mix and site-mixed plaster depends on project scale, desired finish, and budget constraints.

Table of Comparison

| Feature | Ready-Mix Plaster | Site-Mixed Plaster |

|---|---|---|

| Composition | Factory pre-mixed with consistent quality | Manually mixed on-site, variable quality |

| Application | Uniform and smooth finish, easy application | Dependent on worker skill, may vary in finish |

| Time Efficiency | Quick application, saves labor time | Time-consuming mixing and preparation |

| Cost | Higher initial cost, less wastage | Lower material cost, increased labor cost |

| Durability | High durability, consistent strength | Varies with mix accuracy and quality |

| Storage & Handling | Requires proper storage to avoid moisture | Raw materials stored separately on-site |

| Environmental Impact | Less material wastage reduces environmental footprint | Higher material wastage, potential pollution |

Understanding Ready-Mix Plaster and Site-Mixed Plaster

Ready-mix plaster is a pre-blended, factory-prepared mixture that ensures consistent quality, uniform texture, and reduced application time compared to site-mixed plaster. Site-mixed plaster involves manually mixing raw materials like cement, sand, and lime on location, offering flexibility in adjusting the mix but often resulting in variable quality and longer preparation. Choosing between ready-mix and site-mixed plaster depends on project requirements, labor skill levels, and desired finish consistency.

Key Material Differences

Ready-mix plaster is pre-mixed in a factory with precise proportions of cement, lime, sand, and additives, ensuring consistency and reduced labor on site. Site-mixed plaster involves manually blending raw materials like cement, sand, lime, and water directly at the construction site, which can lead to variability in quality and mix ratios. Key material differences include the controlled quality of components and uniformity found in ready-mix plaster versus the customizable but potentially inconsistent nature of site-mixed plaster.

Application Process Compared

Ready-mix plaster offers a consistent blend of pre-measured ingredients that ensures faster and cleaner application compared to site-mixed plaster, which requires manual mixing and can lead to variability in texture and strength. The ready-mix option reduces labor time and minimizes waste due to its precise formulation, whereas site-mixed plaster demands skilled workmanship to achieve a uniform finish. Overall, ready-mix plaster enhances efficiency on-site while maintaining quality control throughout the application process.

Consistency and Quality Control

Ready-mix plaster offers superior consistency and quality control due to factory-controlled production processes, ensuring uniform particle size and precise ingredient proportions. Site-mixed plaster often suffers from variability in water-cement ratios and mixing techniques, leading to inconsistent texture and reduced durability. The controlled environment of ready-mix plasters minimizes human error and contamination, resulting in a more reliable and high-quality finish.

Labor and Time Efficiency

Ready-mix plaster offers superior labor and time efficiency compared to site-mixed plaster by eliminating the need for on-site mixing, reducing labor hours and ensuring consistent quality. Its pre-blended composition minimizes preparation time and accelerates application, significantly cutting project duration. Site-mixed plaster demands skilled labor for accurate mixing ratios, increasing labor costs and potential delays due to inconsistencies.

Cost Factors and Budget Considerations

Ready-mix plaster offers consistent quality and reduced labor costs due to factory-controlled mixing, which can lead to lower overall expenses despite a higher initial price compared to site-mixed plaster. Site-mixed plaster may seem cost-effective upfront because of cheaper raw material purchases, but its variability in mix quality can result in wastage and increased labor time that inflate the budget. Budget considerations favor ready-mix plaster for large-scale projects where time efficiency and material reliability directly impact cost-saving outcomes.

Performance and Durability

Ready-mix plaster offers superior consistency and uniformity in performance due to factory-controlled mixing processes, ensuring optimal strength and crack resistance. Site-mixed plaster often suffers from variability in material proportions and mixing quality, leading to less reliable durability and increased susceptibility to shrinkage and cracking over time. The enhanced performance and long-term durability of ready-mix plaster make it a preferred choice for critical construction applications.

Environmental Impact and Waste Generation

Ready-mix plaster significantly reduces environmental impact by minimizing on-site waste through precise factory-controlled batching and packaging, lowering excess material disposal and dust emissions. Site-mixed plaster often results in inconsistent mixture ratios, leading to higher waste generation and increased resource consumption due to over-mixing or discard of unusable batches. Choosing ready-mix solutions enhances sustainability by optimizing raw material usage and reducing carbon footprint associated with on-site handling and transport.

Suitability for Different Project Types

Ready-mix plaster offers consistent quality and faster application, making it ideal for large-scale commercial projects requiring uniform finishes. Site-mixed plaster allows customization of mix ratios on-site, suiting smaller residential or renovation projects where specific adaptability is needed. Choice between ready-mix and site-mixed plaster depends on project size, complexity, and demand for consistency or flexibility.

Choosing the Right Plaster for Your Project

Ready-mix plaster offers consistent quality, faster application, and reduced labor costs compared to site-mixed plaster, which requires manual blending and can lead to variable results. Selecting ready-mix plaster enhances project efficiency and durability, especially for large-scale or time-sensitive tasks. Site-mixed plaster may suit small projects or custom mix adjustments but demands skilled labor to ensure proper consistency and strength.

Ready-Mix Plaster vs Site-Mixed Plaster Infographic

materialdif.com

materialdif.com