Plaster of Paris sets quickly and provides a hard, durable surface ideal for sculpting and repairing small holes, while joint compound dries slower and is more flexible, making it better suited for finishing drywall seams and creating smooth wall surfaces. Plaster of Paris is powder-based and requires mixing with water before application, whereas joint compound comes pre-mixed or in dry form and is easier to sand and recoat. For projects demanding rapid setting and strong adhesion, Plaster of Paris is preferred, but joint compound excels in larger drywall repairs due to its ease of use and extended working time.

Table of Comparison

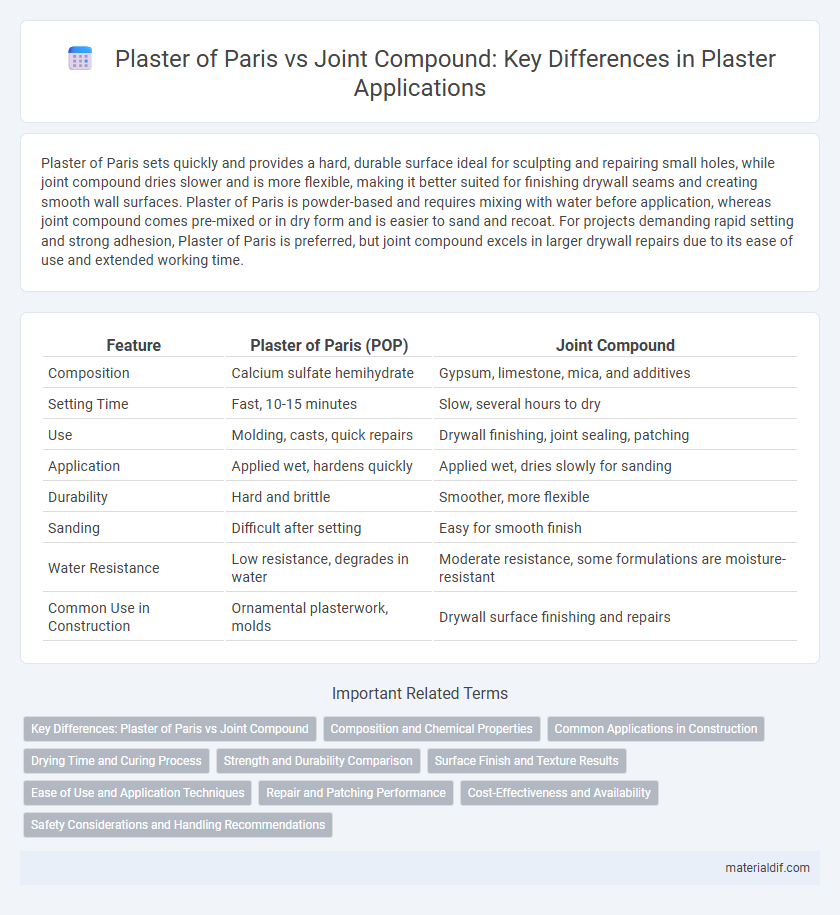

| Feature | Plaster of Paris (POP) | Joint Compound |

|---|---|---|

| Composition | Calcium sulfate hemihydrate | Gypsum, limestone, mica, and additives |

| Setting Time | Fast, 10-15 minutes | Slow, several hours to dry |

| Use | Molding, casts, quick repairs | Drywall finishing, joint sealing, patching |

| Application | Applied wet, hardens quickly | Applied wet, dries slowly for sanding |

| Durability | Hard and brittle | Smoother, more flexible |

| Sanding | Difficult after setting | Easy for smooth finish |

| Water Resistance | Low resistance, degrades in water | Moderate resistance, some formulations are moisture-resistant |

| Common Use in Construction | Ornamental plasterwork, molds | Drywall surface finishing and repairs |

Key Differences: Plaster of Paris vs Joint Compound

Plaster of Paris (POP) sets rapidly due to its chemical composition of calcium sulfate hemihydrate, making it ideal for quick repairs and detailed molds, whereas joint compound dries slowly, allowing extended workability for smoothing drywall seams and finishes. POP hardens through a chemical reaction when mixed with water, resulting in a harder, more brittle surface, while joint compound air-dries to a softer, more flexible finish suited for sanding and layering. Key differences include drying time, texture, application purpose, and the ease of sanding, with joint compound preferred for interior wall finishing and POP used in sculpture, casting, and rapid patching.

Composition and Chemical Properties

Plaster of Paris primarily consists of calcium sulfate hemihydrate (CaSO4* 1/2H2O), which hardens quickly upon hydration by forming gypsum (CaSO4*2H2O), offering rapid setting and high hardness. Joint compound, formulated with gypsum dust mixed with water, polymers, and additives like mica or limestone, provides extended drying time and flexibility for surface finishing. The chemical reactivity of Plaster of Paris allows fast setting and strong bonding, whereas joint compound's polymer content enhances adhesion and workability but lacks the rapid chemical hardening process of Plaster of Paris.

Common Applications in Construction

Plaster of Paris is widely used for creating decorative moldings, ceiling cornices, and quick repairs due to its fast setting time and smooth finish. Joint compound is preferred for drywall finishing, including taping, filling joints, and providing a smooth surface for painting. Construction professionals select plaster of Paris for detailed ornamental work, while joint compound is commonly applied in drywall installation and patching tasks.

Drying Time and Curing Process

Plaster of Paris (POP) dries rapidly, typically within 20 to 30 minutes, making it ideal for fast repairs and detailed moldings, while joint compound has a slower drying time, often requiring 24 to 48 hours depending on thickness and environmental conditions. The curing process of POP is an exothermic chemical reaction where calcium sulfate hemihydrate converts to dihydrate, hardening quickly, whereas joint compound undergoes a physical drying process where moisture evaporates gradually, resulting in a longer setting phase. These differences influence project timelines and application techniques, with POP favored for quick sets and joint compound preferred for smoother finishes and layering.

Strength and Durability Comparison

Plaster of Paris exhibits higher compressive strength and faster setting times compared to joint compound, making it ideal for structural repairs and detailed molding. Joint compound offers greater flexibility and crack resistance, which enhances long-term durability in drywall applications but has lower overall strength. For projects requiring robust and durable finishes, Plaster of Paris provides superior hardness, while joint compound excels in surface smoothness and repair adaptability.

Surface Finish and Texture Results

Plaster of Paris provides a hard, smooth surface finish with a quick drying time, making it ideal for detailed molding and sculpting work. Joint compound, on the other hand, offers a softer, more flexible texture that sands easily, resulting in a seamless surface suited for drywall finishing. The choice between the two depends on desired texture durability and ease of sanding for the final wall surface.

Ease of Use and Application Techniques

Plaster of Paris sets quickly and requires skillful mixing and rapid application, making it less forgiving for beginners compared to joint compound, which offers a longer drying time and easier sanding. Joint compound can be applied in multiple thin layers using standard drywall tools, providing more flexibility for repairs and smooth finishes. In terms of ease of use, joint compound is preferred for patching drywall due to its workability and user-friendly application techniques.

Repair and Patching Performance

Plaster of Paris offers rapid setting and high strength, making it ideal for quick repairs and durable patching in wall and ceiling applications. Joint compound provides superior flexibility and ease of sanding, allowing for smooth finishes and seamless blending with existing surfaces during patching tasks. Both materials excel in repair performance, but Plaster of Paris is preferred for speed and hardness, while joint compound is favored for fine finishing and minor surface corrections.

Cost-Effectiveness and Availability

Plaster of Paris offers a cost-effective solution with rapid setting times ideal for small repairs and detailed moldings, making it widely available in hardware stores and art supply shops. Joint compound, while typically more expensive and slower to dry, provides superior workability and is commonly stocked at large home improvement centers, ensuring accessibility for drywall finishing projects. Cost-effectiveness depends on project scale and purpose, with Plaster of Paris favored for quick, economical fixes and joint compound preferred for comprehensive wall treatments.

Safety Considerations and Handling Recommendations

Plaster of Paris (POP) contains fine gypsum powder that can cause respiratory irritation if inhaled, necessitating the use of protective masks and gloves during handling. Joint compound typically has lower dust levels and contains additives to reduce airborne particles but may cause skin sensitivity, so wearing gloves and ensuring proper ventilation are recommended. Both materials require storing in a dry environment to maintain their effectiveness and prevent hazardous dust exposure.

Plaster of Paris vs Joint compound Infographic

materialdif.com

materialdif.com