Hydrated lime, also known as calcium hydroxide, is produced by adding water to quicklime, making it safer to handle and more suitable for plaster applications due to its smooth texture and slower setting time. Quicklime, or calcium oxide, reacts quickly with water and generates intense heat, requiring careful handling and often used in industrial processes rather than direct plaster mixes. Choosing hydrated lime over quicklime improves workability, reduces cracking risks, and enhances the durability of plaster finishes.

Table of Comparison

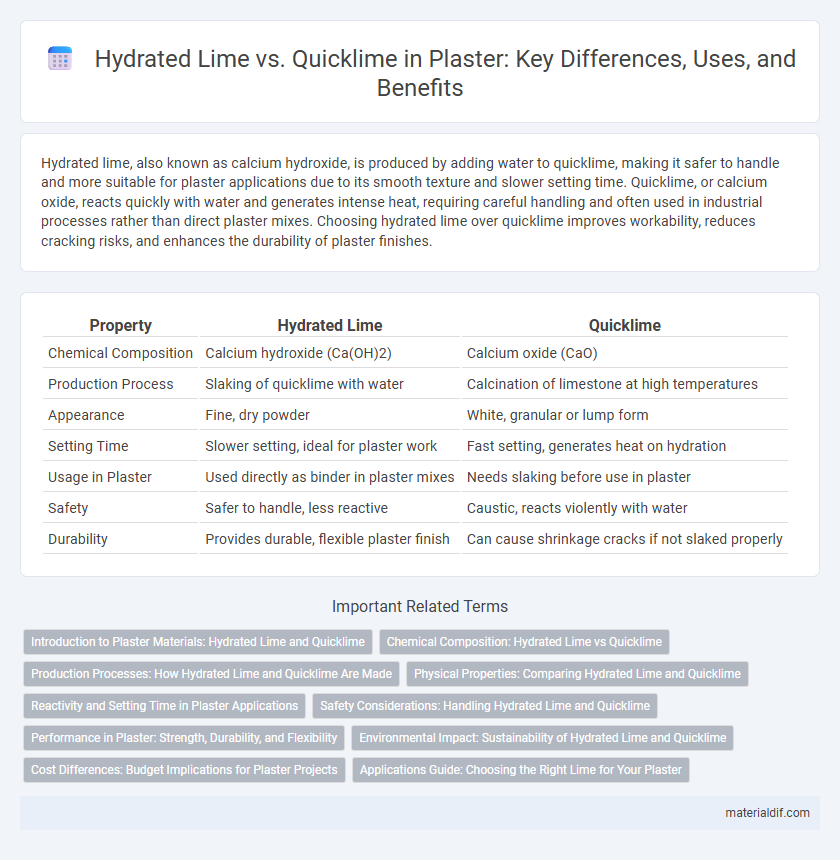

| Property | Hydrated Lime | Quicklime |

|---|---|---|

| Chemical Composition | Calcium hydroxide (Ca(OH)2) | Calcium oxide (CaO) |

| Production Process | Slaking of quicklime with water | Calcination of limestone at high temperatures |

| Appearance | Fine, dry powder | White, granular or lump form |

| Setting Time | Slower setting, ideal for plaster work | Fast setting, generates heat on hydration |

| Usage in Plaster | Used directly as binder in plaster mixes | Needs slaking before use in plaster |

| Safety | Safer to handle, less reactive | Caustic, reacts violently with water |

| Durability | Provides durable, flexible plaster finish | Can cause shrinkage cracks if not slaked properly |

Introduction to Plaster Materials: Hydrated Lime and Quicklime

Hydrated lime and quicklime are essential materials in plaster production, each with distinct chemical compositions and application properties. Hydrated lime, or calcium hydroxide, offers improved workability and slower setting times, making it ideal for smooth finishes and restorations. Quicklime, or calcium oxide, reacts rapidly with water, providing higher heat generation and faster setting useful in specialized plaster formulations.

Chemical Composition: Hydrated Lime vs Quicklime

Hydrated lime, also known as calcium hydroxide (Ca(OH)2), is produced by adding water to quicklime, resulting in a more stable and less reactive substance. Quicklime, or calcium oxide (CaO), is a highly reactive compound obtained by heating limestone, and it reacts vigorously with water during the slaking process. The chemical difference between hydrated lime and quicklime lies in the presence of hydroxide ions in Ca(OH)2, which makes hydrated lime safer and easier to handle in plaster applications.

Production Processes: How Hydrated Lime and Quicklime Are Made

Hydrated lime is produced by adding water to quicklime in a process called slaking, where calcium oxide reacts with water to form calcium hydroxide. Quicklime is created through the calcination of limestone at temperatures around 900degC to 1000degC, driving off carbon dioxide and producing calcium oxide. This difference in production processes results in varying properties and applications for plaster formulations.

Physical Properties: Comparing Hydrated Lime and Quicklime

Hydrated lime consists of calcium hydroxide with a fine, powdery texture, making it easier to mix and apply in plaster compared to quicklime, which is calcium oxide and appears as a hard, granular solid. Quicklime undergoes an exothermic reaction when water is added, resulting in slaking that produces heat and transforms it into hydrated lime, altering its physical state. The lower density and higher moisture content of hydrated lime improve workability and reduce setting time in plaster applications compared to the more reactive and unstable quicklime.

Reactivity and Setting Time in Plaster Applications

Hydrated lime exhibits lower reactivity and a longer setting time compared to quicklime, making it ideal for controlled plaster curing and enhanced workability. Quicklime reacts rapidly upon hydration, generating heat and accelerating the setting process, which requires careful handling to prevent cracking in plaster applications. Selecting between hydrated lime and quicklime depends on the desired plaster performance, with hydrated lime favored for gradual strength development and quicklime for faster setting demands.

Safety Considerations: Handling Hydrated Lime and Quicklime

Handling hydrated lime requires protective gear to prevent skin irritation and respiratory issues due to its caustic nature and fine dust particles. Quicklime poses higher hazards, necessitating strict safety measures such as wearing gloves, goggles, and masks, because it reacts violently with water, generating intense heat and corrosive steam. Proper storage in moisture-proof containers and adequate ventilation are critical to minimize risks associated with both types of lime in plaster applications.

Performance in Plaster: Strength, Durability, and Flexibility

Hydrated lime in plaster offers improved flexibility and workability, reducing cracking and enhancing long-term durability compared to quicklime. Quicklime provides higher initial strength but can lead to brittleness and shrinkage during curing. Plasters with hydrated lime exhibit better adhesion and resilience, making them preferable for applications requiring balanced strength and flexibility.

Environmental Impact: Sustainability of Hydrated Lime and Quicklime

Hydrated lime, produced by adding water to quicklime, has a lower carbon footprint during use due to its lower energy demand in application compared to quicklime, which requires higher temperatures and more energy to produce. Quicklime production releases significant CO2, contributing to environmental pollution, whereas hydrated lime's processing and application generate fewer emissions, supporting better sustainability. Choosing hydrated lime in plaster formulations enhances eco-friendliness due to reduced energy consumption and lower greenhouse gas emissions throughout its lifecycle.

Cost Differences: Budget Implications for Plaster Projects

Hydrated lime generally costs more than quicklime due to additional processing and handling expenses, impacting plaster project budgets significantly. Quicklime is cheaper but requires careful management of its exothermic reaction and moisture sensitivity, potentially increasing labor and safety costs. Choosing between hydrated lime and quicklime depends on balancing upfront material expenses with long-term project efficiency and risk factors.

Applications Guide: Choosing the Right Lime for Your Plaster

Hydrated lime, with its fine texture and slower setting time, is ideal for interior plaster applications requiring smooth finishes and greater workability, while quicklime, known for its rapid setting and higher reactivity, suits exterior plasters needing enhanced durability and moisture resistance. Understanding the chemical properties and curing processes of each lime type ensures optimal adhesion, breathability, and longevity in plasterwork. Selecting the appropriate lime based on project requirements directly impacts performance, preventing common issues like cracking or premature deterioration.

Hydrated Lime vs Quicklime Infographic

materialdif.com

materialdif.com