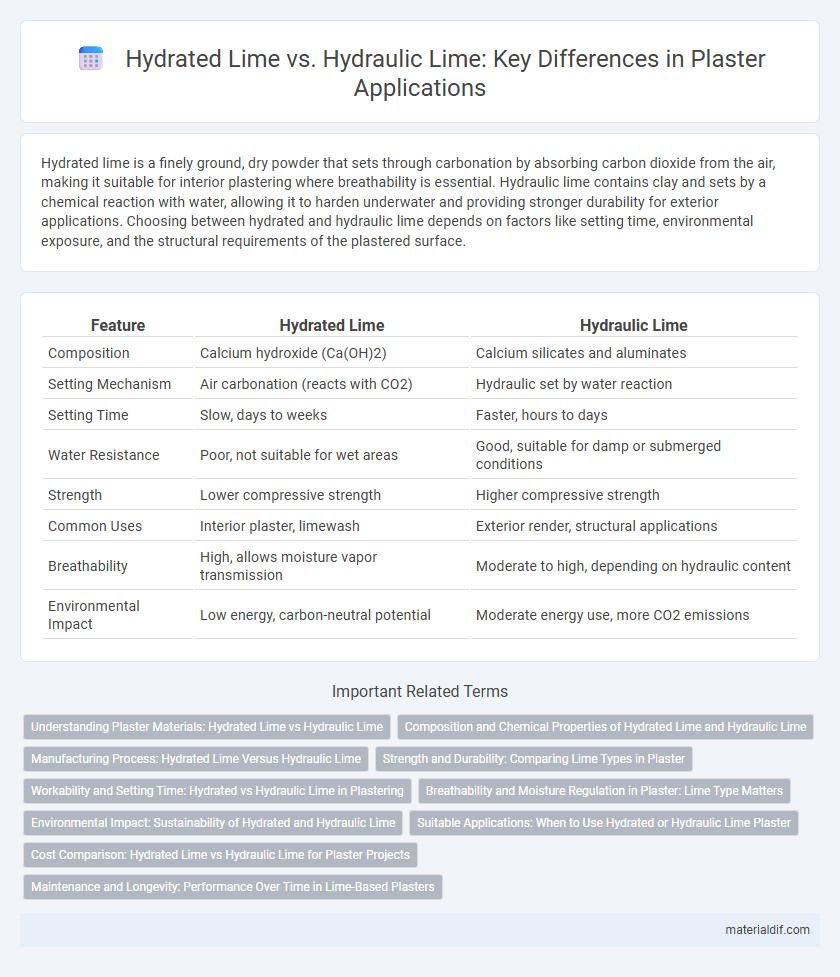

Hydrated lime is a finely ground, dry powder that sets through carbonation by absorbing carbon dioxide from the air, making it suitable for interior plastering where breathability is essential. Hydraulic lime contains clay and sets by a chemical reaction with water, allowing it to harden underwater and providing stronger durability for exterior applications. Choosing between hydrated and hydraulic lime depends on factors like setting time, environmental exposure, and the structural requirements of the plastered surface.

Table of Comparison

| Feature | Hydrated Lime | Hydraulic Lime |

|---|---|---|

| Composition | Calcium hydroxide (Ca(OH)2) | Calcium silicates and aluminates |

| Setting Mechanism | Air carbonation (reacts with CO2) | Hydraulic set by water reaction |

| Setting Time | Slow, days to weeks | Faster, hours to days |

| Water Resistance | Poor, not suitable for wet areas | Good, suitable for damp or submerged conditions |

| Strength | Lower compressive strength | Higher compressive strength |

| Common Uses | Interior plaster, limewash | Exterior render, structural applications |

| Breathability | High, allows moisture vapor transmission | Moderate to high, depending on hydraulic content |

| Environmental Impact | Low energy, carbon-neutral potential | Moderate energy use, more CO2 emissions |

Understanding Plaster Materials: Hydrated Lime vs Hydraulic Lime

Hydrated lime, also known as calcium hydroxide, is a dry powder obtained by adding water to quicklime and is primarily used in plaster for its high workability and smooth finish. Hydraulic lime contains natural impurities that react with water to set more quickly and gain strength through hydraulic reactions, making it suitable for damp environments and exterior applications. Understanding the distinct setting properties and durability of hydrated versus hydraulic lime is crucial in selecting the appropriate plaster material for restoration or construction projects.

Composition and Chemical Properties of Hydrated Lime and Hydraulic Lime

Hydrated lime, primarily composed of calcium hydroxide (Ca(OH)2), exhibits high alkalinity and solubility, making it suitable for applications requiring rapid setting and high pH levels. Hydraulic lime contains varying amounts of clay and silica, forming calcium silicates and aluminates that enable it to set underwater through a chemical reaction with water, providing greater durability and water resistance. The chemical difference lies in hydrated lime's purely calcium hydroxide composition versus hydraulic lime's mixture of calcium hydroxide, silicates, and aluminates, affecting their setting times and strength development.

Manufacturing Process: Hydrated Lime Versus Hydraulic Lime

Hydrated lime is produced by calcining limestone to create quicklime, which is then slaked with water to form a fine, dry powder known as calcium hydroxide. Hydraulic lime undergoes a similar initial calcination process but incorporates clay or silica impurities, enabling it to set under water through hydraulic reactions. The manufacturing differences result in hydrated lime being primarily air-setting with easier handling, while hydraulic lime's composition provides stronger, moisture-resistant characteristics ideal for durable plasters.

Strength and Durability: Comparing Lime Types in Plaster

Hydraulic lime offers superior strength and durability compared to hydrated lime due to its ability to set underwater and resist weathering, making it ideal for exterior plaster applications. Hydrated lime, primarily air-setting, provides a softer finish but lacks the compressive strength and wear resistance of hydraulic lime. Choosing hydraulic lime enhances plaster longevity in exposed environments, while hydrated lime suits interior or decorative uses where flexibility and breathability are prioritized.

Workability and Setting Time: Hydrated vs Hydraulic Lime in Plastering

Hydrated lime offers superior workability due to its fine texture and slower setting time, allowing for easier application and extended working periods in plastering. Hydraulic lime sets faster as it reacts with water and carbon dioxide, providing quicker strength gain but requiring more skill to manage during application. Selecting between hydrated and hydraulic lime depends on project needs for setting time flexibility and finishing precision in plastering work.

Breathability and Moisture Regulation in Plaster: Lime Type Matters

Hydraulic lime contains clay minerals that enable it to set underwater, offering moderate breathability and moisture regulation ideal for damp environments. Hydrated lime, derived from slaked quicklime, provides superior porosity and vapor permeability, enhancing breathability and allowing walls to effectively manage moisture. Choosing between hydrated and hydraulic lime directly impacts plaster performance in historic and breathable building applications.

Environmental Impact: Sustainability of Hydrated and Hydraulic Lime

Hydrated lime, produced by slaking quicklime with water, typically generates lower CO2 emissions during processing compared to hydraulic lime, which requires higher kiln temperatures for its clay component. Hydraulic lime offers enhanced durability and carbonates over time by absorbing CO2, contributing to long-term carbon sequestration, a key factor in sustainable building materials. Both limes provide eco-friendly alternatives to Portland cement, but hydraulic lime's balance of mechanical strength and environmental benefits makes it particularly suitable for sustainable construction projects.

Suitable Applications: When to Use Hydrated or Hydraulic Lime Plaster

Hydrated lime plaster is ideal for interior walls and ceilings where breathability and flexibility are required, making it suitable for historic buildings and restoration projects that need non-rigid finishes. Hydraulic lime plaster, which sets through hydraulic action, is better suited for exterior applications and damp environments due to its enhanced water resistance and faster curing times. Choosing between hydrated and hydraulic lime plaster depends on environmental exposure and structural needs, with hydrated lime preferred for dry, flexible finishes and hydraulic lime for durability in moist conditions.

Cost Comparison: Hydrated Lime vs Hydraulic Lime for Plaster Projects

Hydrated lime typically costs less than hydraulic lime, making it a more budget-friendly option for plaster projects that require softer, more breathable finishes. Hydraulic lime, due to its faster setting time and superior strength, commands a higher price but offers enhanced durability and moisture resistance for exterior or structural applications. Choosing between hydrated and hydraulic lime depends on balancing initial material costs with long-term performance requirements in plaster work.

Maintenance and Longevity: Performance Over Time in Lime-Based Plasters

Hydraulic lime offers superior durability and weather resistance compared to hydrated lime, making it more suitable for external lime-based plasters exposed to moisture. Maintenance frequency decreases with hydraulic lime plasters due to their ability to harden through reaction with water, providing long-term structural integrity. Hydrated lime, while easier to work with and suitable for interior applications, requires more frequent upkeep because it relies on carbonation, which is slower and less effective in damp conditions.

Hydrated lime vs Hydraulic lime Infographic

materialdif.com

materialdif.com