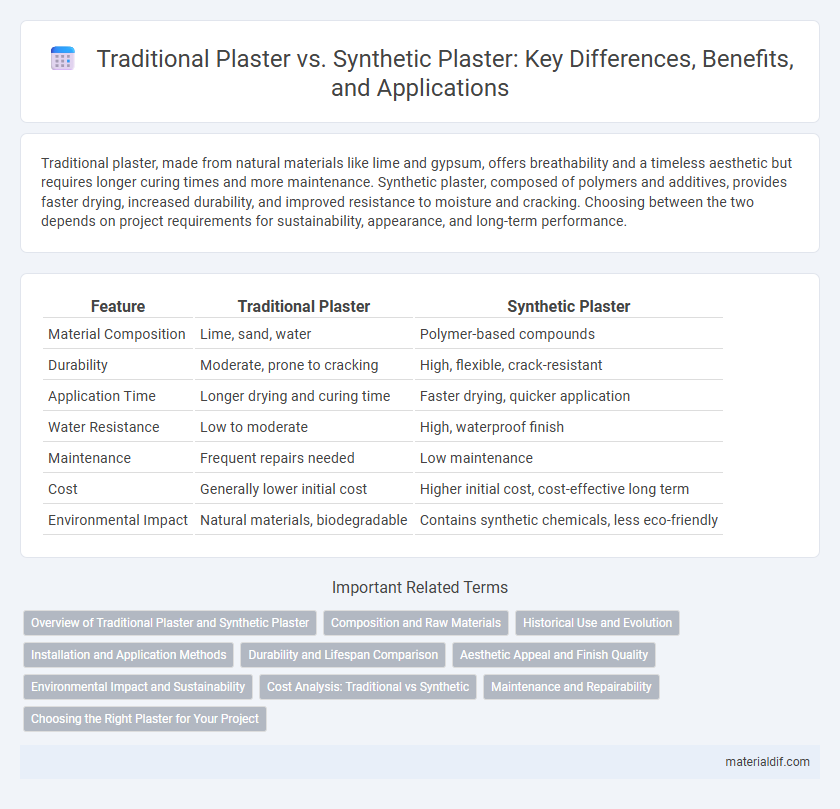

Traditional plaster, made from natural materials like lime and gypsum, offers breathability and a timeless aesthetic but requires longer curing times and more maintenance. Synthetic plaster, composed of polymers and additives, provides faster drying, increased durability, and improved resistance to moisture and cracking. Choosing between the two depends on project requirements for sustainability, appearance, and long-term performance.

Table of Comparison

| Feature | Traditional Plaster | Synthetic Plaster |

|---|---|---|

| Material Composition | Lime, sand, water | Polymer-based compounds |

| Durability | Moderate, prone to cracking | High, flexible, crack-resistant |

| Application Time | Longer drying and curing time | Faster drying, quicker application |

| Water Resistance | Low to moderate | High, waterproof finish |

| Maintenance | Frequent repairs needed | Low maintenance |

| Cost | Generally lower initial cost | Higher initial cost, cost-effective long term |

| Environmental Impact | Natural materials, biodegradable | Contains synthetic chemicals, less eco-friendly |

Overview of Traditional Plaster and Synthetic Plaster

Traditional plaster, primarily composed of lime, gypsum, or cement, offers excellent breathability and natural moisture regulation, making it suitable for older, historic buildings. Synthetic plaster, made from acrylics or polymers, provides enhanced durability, flexibility, and water resistance, ideal for modern construction requiring low maintenance. Both types serve distinct purposes depending on the building's structural needs and environmental conditions.

Composition and Raw Materials

Traditional plaster primarily consists of natural materials such as lime, sand, and water, often incorporating organic binders like animal hair or straw for reinforcement. Synthetic plaster, on the other hand, is formulated using chemical compounds such as polymers, gypsum, and acrylic resins, designed to enhance durability, flexibility, and moisture resistance. The raw materials in synthetic plaster allow for faster curing times and improved performance under varying environmental conditions compared to the mineral-based components of traditional plaster.

Historical Use and Evolution

Traditional plaster, composed primarily of lime, sand, and water, has been used for thousands of years, dating back to ancient civilizations such as Egypt and Greece, known for its breathability and durability. Synthetic plaster, developed in the 20th century, incorporates polymer resins and additives, offering faster drying times, improved flexibility, and enhanced weather resistance. The evolution from traditional to synthetic plaster reflects advances in material science aimed at meeting modern construction demands while preserving aesthetic finishes.

Installation and Application Methods

Traditional plaster requires a multi-layer application process, typically involving base coats and finishing layers, which demand skilled labor and longer drying times. Synthetic plaster offers easier installation through ready-mixed formulations, allowing for faster application and quicker setting, often requiring fewer skilled workers. Both types benefit from proper surface preparation, but synthetic plaster adapts better to various substrates and climate conditions due to its flexible composition.

Durability and Lifespan Comparison

Traditional plaster, composed primarily of lime or gypsum, offers excellent breathability and can last over a century when properly maintained, making it highly durable for historic restorations. Synthetic plaster, often based on acrylic or polymer compounds, provides enhanced resistance to cracking, moisture, and UV damage, typically extending its functional lifespan to 30-50 years under normal conditions. The choice between traditional and synthetic plaster depends on the specific durability requirements and environmental exposure, with synthetic options favored for modern buildings requiring lower maintenance and faster application.

Aesthetic Appeal and Finish Quality

Traditional plaster offers a rich, timeless aesthetic with natural textures and a breathable finish that enhances wall durability and moisture regulation. Synthetic plaster provides a uniform, smooth surface with greater resistance to cracking and weathering, ensuring long-lasting vibrant colors and a modern appearance. Choosing between the two depends on the desired finish quality, with traditional plaster favored for classic interiors and synthetic plaster preferred for contemporary designs demanding low maintenance.

Environmental Impact and Sustainability

Traditional plaster, typically made from natural materials like lime and gypsum, offers excellent breathability and biodegradability, reducing environmental impact through minimal chemical processing. Synthetic plaster, composed of polymers and additives, often contains volatile organic compounds (VOCs) that can contribute to indoor air pollution and have a higher carbon footprint due to energy-intensive manufacturing. Choosing traditional plaster supports sustainability goals by promoting eco-friendly resource use and facilitating easier recycling or disposal at the end of its lifecycle.

Cost Analysis: Traditional vs Synthetic

Traditional plaster typically incurs higher initial costs due to labor-intensive application processes and longer drying times, whereas synthetic plaster offers reduced labor expenses and quicker installation. Synthetic plaster often provides better cost efficiency over time because of its durability and lower maintenance requirements compared to traditional lime or gypsum-based plaster. Evaluating lifecycle expenses reveals synthetic options can yield significant savings despite slightly higher material prices.

Maintenance and Repairability

Traditional plaster offers excellent durability and is easier to repair with matching materials, making spot fixes seamless and maintaining aesthetic consistency. Synthetic plaster, often composed of acrylic or polymer-based materials, requires specialized products for maintenance and can be less forgiving during repairs, potentially leading to visible patches. Regular upkeep of traditional plaster involves simple reapplication techniques, whereas synthetic plaster may demand more technical interventions to preserve its surface integrity.

Choosing the Right Plaster for Your Project

Traditional plaster, composed of lime or gypsum, offers natural breathability and durability, ideal for historic restorations and environments requiring moisture regulation. Synthetic plaster, made from acrylic or polymer-based materials, provides faster drying times, enhanced flexibility, and resistance to cracking, suitable for modern construction and areas prone to structural movement. Selecting the right plaster depends on project requirements, such as environmental conditions, surface type, and desired finish longevity.

Traditional plaster vs Synthetic plaster Infographic

materialdif.com

materialdif.com