Fire-resistant plaster contains special additives like glass fibers and vermiculite that enhance its ability to withstand high temperatures, making it safer for use in areas prone to fire hazards. Standard plaster lacks these fire-retardant components, making it more susceptible to cracking and damage when exposed to heat. Choosing fire-resistant plaster improves building safety by slowing fire spread and maintaining structural integrity longer during a fire event.

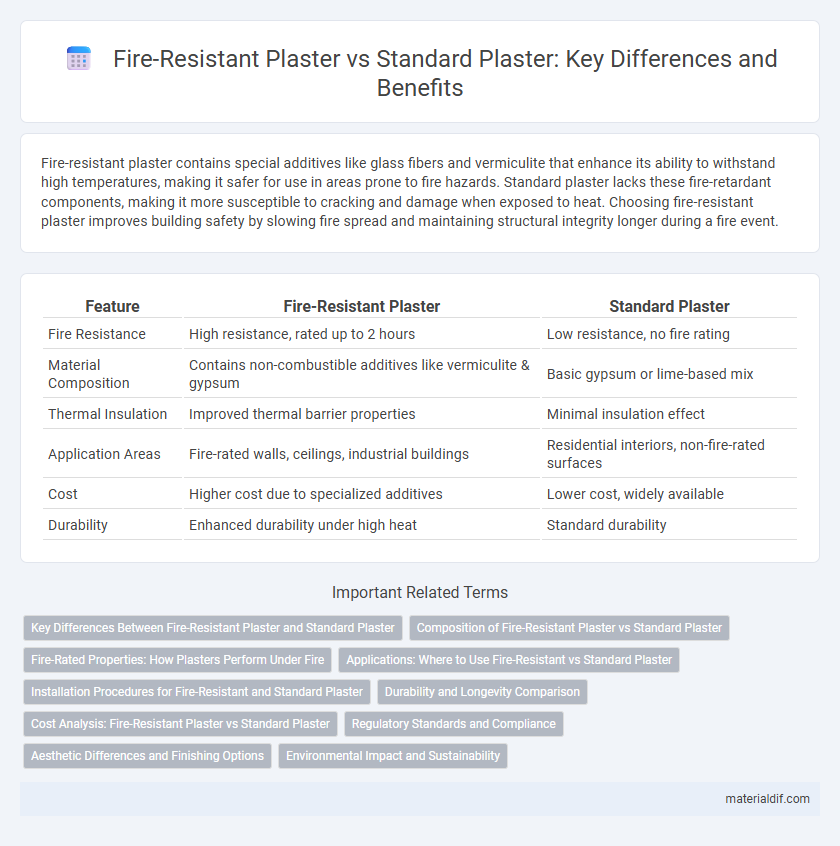

Table of Comparison

| Feature | Fire-Resistant Plaster | Standard Plaster |

|---|---|---|

| Fire Resistance | High resistance, rated up to 2 hours | Low resistance, no fire rating |

| Material Composition | Contains non-combustible additives like vermiculite & gypsum | Basic gypsum or lime-based mix |

| Thermal Insulation | Improved thermal barrier properties | Minimal insulation effect |

| Application Areas | Fire-rated walls, ceilings, industrial buildings | Residential interiors, non-fire-rated surfaces |

| Cost | Higher cost due to specialized additives | Lower cost, widely available |

| Durability | Enhanced durability under high heat | Standard durability |

Key Differences Between Fire-Resistant Plaster and Standard Plaster

Fire-resistant plaster contains additives like vermiculite or gypsum that enhance its ability to withstand high temperatures and prevent fire spread, unlike standard plaster which offers limited heat resistance. The thermal conductivity of fire-resistant plaster is significantly lower, providing better insulation and protection for structural elements during fires. Standard plaster primarily serves aesthetic and surface protection purposes, whereas fire-resistant plaster is engineered to meet specific fire safety codes and standards.

Composition of Fire-Resistant Plaster vs Standard Plaster

Fire-resistant plaster contains additives such as vermiculite, fiberglass, or cementitious compounds that enhance its thermal insulation and fire-retardant properties, unlike standard plaster which primarily consists of gypsum, lime, and sand. The incorporation of non-combustible materials in fire-resistant plaster increases its ability to withstand high temperatures and prevent flame spread. Standard plaster lacks these specialized components, making it less effective in resisting fire exposure.

Fire-Rated Properties: How Plasters Perform Under Fire

Fire-resistant plaster contains specialized additives like vermiculite and gypsum, which significantly improve its ability to withstand high temperatures by slowing heat transfer and preventing structural damage during a fire. Standard plaster lacks these fire-retardant components, making it more susceptible to cracking, charring, and failure under intense heat exposure. Fire-rated plaster systems are tested to meet strict fire resistance ratings, often providing up to 2 hours of fire protection, essential for enhancing building safety and compliance with fire codes.

Applications: Where to Use Fire-Resistant vs Standard Plaster

Fire-resistant plaster is ideal for use in commercial buildings, industrial facilities, and areas requiring compliance with fire safety codes due to its ability to withstand high temperatures and prevent the spread of flames. Standard plaster is commonly applied in residential interiors, decorative surfaces, and non-critical areas where fire resistance is not a primary concern. Choosing fire-resistant plaster in stairwells, corridors, and structural elements enhances occupant safety and meets regulatory standards.

Installation Procedures for Fire-Resistant and Standard Plaster

Fire-resistant plaster requires precise mixing with specialized additives and must be applied in multiple, evenly spread layers to enhance its heat-resistant properties, differing significantly from standard plaster's simpler single-coat application. Installation of fire-resistant plaster involves curing at controlled temperatures to achieve optimal fire insulation, while standard plaster typically air-dries without the need for temperature regulation. The additional steps in fire-resistant plaster installation are essential for meeting building safety codes and improving structural fire protection.

Durability and Longevity Comparison

Fire-resistant plaster offers superior durability compared to standard plaster by incorporating additives such as vermiculite or gypsum that enhance its resistance to heat and prevent cracking or spalling under high temperatures. Standard plaster, typically composed of lime, sand, and water, lacks thermal resistance, making it more prone to damage and deterioration when exposed to fire or extreme heat over time. The longevity of fire-resistant plaster is substantially greater in fire-prone environments, maintaining structural integrity and reducing maintenance costs significantly.

Cost Analysis: Fire-Resistant Plaster vs Standard Plaster

Fire-resistant plaster generally costs 20-40% more than standard plaster due to its specialized materials designed to withstand high temperatures. While upfront expenses are higher, fire-resistant plaster can reduce long-term costs by enhancing fire safety and potentially lowering insurance premiums. Standard plaster remains more budget-friendly initially but lacks the durability and protection against fire hazards offered by fire-resistant alternatives.

Regulatory Standards and Compliance

Fire-resistant plaster complies with stringent regulatory standards such as ASTM E119 and UL 263, ensuring it provides effective fire protection and meets building code requirements. Standard plaster lacks these certifications, offering limited or no fire resistance, which restricts its use in fire-rated assemblies. Compliance with fire safety regulations is critical for fire-resistant plaster in commercial and industrial constructions to enhance occupant safety and legal adherence.

Aesthetic Differences and Finishing Options

Fire-resistant plaster offers enhanced durability and safety without compromising aesthetic appeal, featuring a denser texture that can affect smoothness compared to standard plaster. Standard plaster provides a more refined, smooth finish ideal for decorative detailing and intricate molding, while fire-resistant plaster typically requires specialized finishing techniques to achieve similar visual elegance. Both types support various finishing options, but fire-resistant plaster may limit certain high-gloss or delicate surface treatments due to its robust composition.

Environmental Impact and Sustainability

Fire-resistant plaster typically contains additives such as vermiculite or perlite that enhance thermal insulation and reduce combustible material content, thereby lowering its environmental footprint compared to standard plaster which mainly comprises gypsum and lacks specialized fire-retardant properties. Sustainable fire-resistant plaster formulations often incorporate recycled materials and contribute to improved indoor air quality by minimizing toxic emissions during fire exposure. Standard plaster, although widely used and cost-effective, generally offers lower durability and less eco-friendly disposal options, resulting in a comparatively higher environmental impact across its lifecycle.

Fire-Resistant Plaster vs Standard Plaster Infographic

materialdif.com

materialdif.com