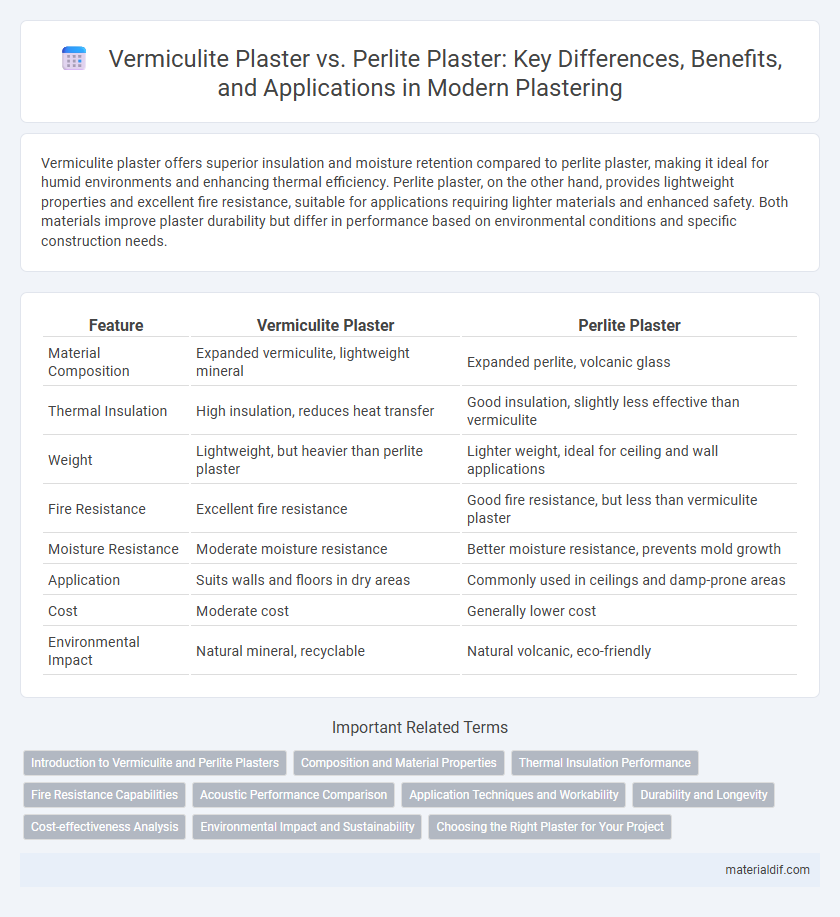

Vermiculite plaster offers superior insulation and moisture retention compared to perlite plaster, making it ideal for humid environments and enhancing thermal efficiency. Perlite plaster, on the other hand, provides lightweight properties and excellent fire resistance, suitable for applications requiring lighter materials and enhanced safety. Both materials improve plaster durability but differ in performance based on environmental conditions and specific construction needs.

Table of Comparison

| Feature | Vermiculite Plaster | Perlite Plaster |

|---|---|---|

| Material Composition | Expanded vermiculite, lightweight mineral | Expanded perlite, volcanic glass |

| Thermal Insulation | High insulation, reduces heat transfer | Good insulation, slightly less effective than vermiculite |

| Weight | Lightweight, but heavier than perlite plaster | Lighter weight, ideal for ceiling and wall applications |

| Fire Resistance | Excellent fire resistance | Good fire resistance, but less than vermiculite plaster |

| Moisture Resistance | Moderate moisture resistance | Better moisture resistance, prevents mold growth |

| Application | Suits walls and floors in dry areas | Commonly used in ceilings and damp-prone areas |

| Cost | Moderate cost | Generally lower cost |

| Environmental Impact | Natural mineral, recyclable | Natural volcanic, eco-friendly |

Introduction to Vermiculite and Perlite Plasters

Vermiculite plaster is a lightweight, insulating material made from expanded vermiculite, known for its excellent fire resistance and thermal insulation properties. Perlite plaster, composed of expanded volcanic glass, offers superior moisture resistance and breathability, making it ideal for damp environments. Both plasters serve as eco-friendly alternatives to traditional plaster with distinct benefits tailored to specific construction needs.

Composition and Material Properties

Vermiculite plaster consists of expanded vermiculite mixed with binder materials, providing excellent insulation and fire resistance due to its layered, mineral structure. Perlite plaster is made from expanded volcanic glass particles, offering lightweight properties and superior thermal insulation with high porosity and low density. Both materials enhance plaster durability, but vermiculite tends to have better moisture retention, while perlite excels in breathability and resistance to cracking.

Thermal Insulation Performance

Vermiculite plaster offers superior thermal insulation due to its high porosity and moisture resistance, making it an effective barrier against heat transfer in both hot and cold environments. Perlite plaster provides good insulation as well, but with a slightly lower R-value compared to vermiculite, ideal for lightweight applications where thermal efficiency and fire resistance are required. Choosing between vermiculite and perlite plaster depends on the specific insulation needs, with vermiculite excelling in thermal retention and perlite favored for its low density and fireproof qualities.

Fire Resistance Capabilities

Vermiculite plaster offers superior fire resistance due to its natural ability to withstand high temperatures and insulate against heat penetration, making it ideal for fireproofing applications. Perlite plaster also provides effective fire resistance by forming a protective barrier that slows heat transfer, but it generally has a lower thermal endurance compared to vermiculite. Both materials enhance fire safety, but vermiculite's expanded mica composition delivers enhanced durability and longer-lasting fire protection in plaster formulations.

Acoustic Performance Comparison

Vermiculite plaster offers superior acoustic insulation due to its layered, lightweight structure that effectively absorbs sound waves and reduces noise transmission in walls and ceilings. Perlite plaster, while also providing some soundproofing benefits, generally exhibits lower sound absorption capacity because of its more porous, less dense granules. Studies indicate that vermiculite plaster can achieve Noise Reduction Coefficient (NRC) values up to 0.75, surpassing typical perlite plaster NRC values around 0.55, making vermiculite plaster a preferred choice for enhanced acoustic performance in building applications.

Application Techniques and Workability

Vermiculite plaster offers superior thermal insulation and moisture resistance, making it ideal for exterior walls and ceilings, while perlite plaster excels in lightweight, fire-resistant interior applications such as drywall finishing. Workability of vermiculite plaster requires careful mixing to avoid clumping and typically needs troweling with moderate pressure, whereas perlite plaster is easier to apply due to its finer texture and supports faster drying times. Application techniques for vermiculite involve layering to build thickness and enhance insulation, whereas perlite plaster benefits from smooth, thin coats to achieve a uniform surface finish.

Durability and Longevity

Vermiculite plaster exhibits superior durability due to its enhanced resistance to cracking and moisture absorption, making it ideal for long-term applications in both interior and exterior surfaces. Perlite plaster, while lightweight and offering excellent thermal insulation, tends to be less durable under heavy wear or exposure to harsh environmental conditions, which can reduce its longevity. Choosing vermiculite plaster ensures a longer lifespan and sustained structural integrity in construction projects requiring robust performance.

Cost-effectiveness Analysis

Vermiculite plaster generally offers superior thermal insulation and fire resistance compared to perlite plaster, resulting in long-term energy savings despite its higher initial cost. Perlite plaster, being lighter and more affordable upfront, suits budget-conscious projects but may require additional insulation measures, increasing overall expenses. Evaluating lifecycle costs reveals vermiculite plaster's enhanced durability and reduced maintenance needs often provide better economic value over time.

Environmental Impact and Sustainability

Vermiculite plaster offers superior environmental benefits due to its natural exfoliation process that requires less energy during production compared to perlite plaster's calcination method. The lightweight, fire-resistant properties of vermiculite contribute to enhanced building insulation with lower carbon footprints, supporting sustainable construction practices. In contrast, perlite plaster, while also recyclable and non-toxic, involves higher thermal processing emissions, making vermiculite the more eco-friendly choice for environmentally conscious projects.

Choosing the Right Plaster for Your Project

Vermiculite plaster offers superior insulation and fire resistance, making it ideal for energy-efficient and safety-focused projects, while perlite plaster excels in lightweight applications with excellent moisture resistance. Selecting the right plaster depends on project requirements such as thermal performance, weight considerations, and environmental conditions. Understanding the specific benefits of vermiculite versus perlite plaster ensures optimal durability and functionality tailored to your construction needs.

Vermiculite Plaster vs Perlite Plaster Infographic

materialdif.com

materialdif.com