Troweling plaster creates a smooth, durable finish by allowing precise control and manual texture adjustment, ideal for smaller or detailed areas. Spraying plaster offers faster application and consistent coverage on large surfaces, reducing labor time but requiring skilled technique for even results. Choosing between troweling and spraying depends on project size, desired texture, and finish quality requirements.

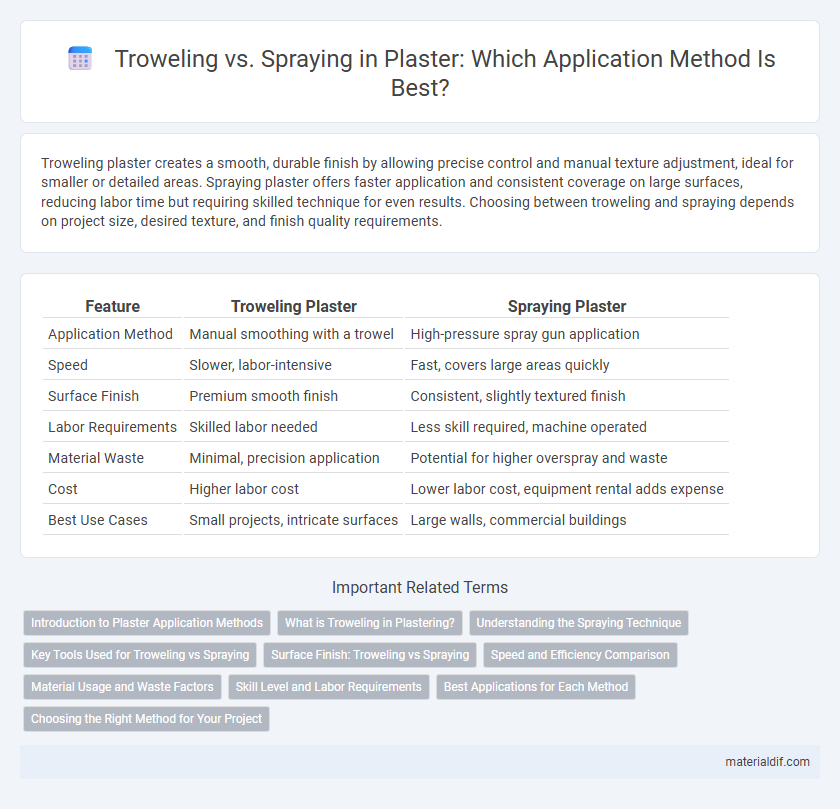

Table of Comparison

| Feature | Troweling Plaster | Spraying Plaster |

|---|---|---|

| Application Method | Manual smoothing with a trowel | High-pressure spray gun application |

| Speed | Slower, labor-intensive | Fast, covers large areas quickly |

| Surface Finish | Premium smooth finish | Consistent, slightly textured finish |

| Labor Requirements | Skilled labor needed | Less skill required, machine operated |

| Material Waste | Minimal, precision application | Potential for higher overspray and waste |

| Cost | Higher labor cost | Lower labor cost, equipment rental adds expense |

| Best Use Cases | Small projects, intricate surfaces | Large walls, commercial buildings |

Introduction to Plaster Application Methods

Plaster application methods vary primarily between troweling and spraying, each offering distinct advantages for surface finishing. Troweling provides precise control and a smooth, polished appearance suited for detailed work and smaller areas, while spraying enables faster coverage and uniform texture on larger surfaces. Understanding these techniques helps optimize plaster adhesion, durability, and aesthetic outcomes tailored to specific construction needs.

What is Troweling in Plastering?

Troweling in plastering is the manual application and smoothing of plaster using a flat, rectangular tool called a trowel. This technique allows for precise control over the thickness and texture of the plaster, creating a smooth, even surface ideal for finishing walls and ceilings. Troweling enhances the plaster's adhesion and durability by compressing the material and eliminating air pockets.

Understanding the Spraying Technique

Spraying plaster involves using a compressor and spray gun to apply a consistent and even coat, significantly reducing labor time compared to traditional troweling. This technique ensures better adhesion and uniform thickness, ideal for large surfaces and complex architectural details. Mastery of pressure control and nozzle adjustments is essential for achieving a smooth finish and minimizing material waste.

Key Tools Used for Troweling vs Spraying

Troweling utilizes hand tools such as steel or plastic trowels, hawks, and floats to apply and smooth plaster surfaces with precision and control. Spraying involves pneumatic or electric plaster sprayers, which allow for rapid, even application over large areas, often requiring subsequent hand-finishing with trowels or sponges. Choosing between troweling and spraying depends on project scale and desired texture, with troweling offering finer detail and spraying optimizing speed.

Surface Finish: Troweling vs Spraying

Troweling produces a smooth, dense surface finish that enhances the plaster's durability and aesthetic appeal through manual precision. Spraying creates a uniform, textured finish ideal for covering large surfaces quickly while maintaining consistent thickness. Surface texture from troweling tends to be finer and more polished, whereas spraying offers a rougher, more textured appearance suited for outdoor or decorative applications.

Speed and Efficiency Comparison

Spraying plaster significantly increases application speed by covering large surface areas rapidly, reducing labor time compared to troweling. Troweling offers greater control and finish precision but is labor-intensive and slower, suitable for detailed or small-scale projects. For high-volume jobs prioritizing efficiency, spraying is the preferred method due to its faster coverage and minimized manual effort.

Material Usage and Waste Factors

Troweling plaster allows for precise application and minimizes material waste by controlling thickness and coverage, resulting in less overspray and rebound loss compared to spraying. Spraying plaster, while faster for large surfaces, often leads to higher material consumption due to overspray and bounce-back, increasing waste and cleanup requirements. Optimizing material usage in troweling reduces costs and improves finish quality, whereas spraying demands careful calibration to mitigate excess plaster use and environmental impact.

Skill Level and Labor Requirements

Troweling plaster demands a higher skill level due to the need for precision and smooth finishes, requiring experienced craftsmen for optimal results. In contrast, spraying plaster reduces labor intensity by covering large surfaces quickly, though it requires specialized equipment and basic operator training. Labor costs are typically higher for troweling because of longer application times and the need for skilled workers.

Best Applications for Each Method

Troweling plaster offers precise control and a smooth, polished finish, ideal for small to medium-sized surfaces and intricate architectural details. Spraying plaster efficiently covers large areas like walls and ceilings, making it suitable for big projects and faster application times. Choosing between troweling and spraying depends on the project scale, desired texture, and finish quality.

Choosing the Right Method for Your Project

Troweling offers precise control and a smooth finish ideal for smaller surfaces or decorative plaster applications, while spraying provides faster coverage suited for large walls and ceilings. Selecting the right method depends on project scale, desired texture, and finish quality, with troweling excelling in detail work and spraying maximizing efficiency. Accurate assessment of surface area and plaster type ensures optimal application technique, balancing time, labor cost, and aesthetic requirements.

Troweling vs Spraying Infographic

materialdif.com

materialdif.com