Sand plaster offers superior durability and the flexibility to customize mixtures according to specific construction needs, making it ideal for traditional and heavy-duty applications. Ready-mix plaster ensures consistent quality, faster application, and reduced labor time, which enhances efficiency for large-scale projects. Choosing between sand plaster and ready-mix plaster depends on balancing cost, project scale, and required finish quality.

Table of Comparison

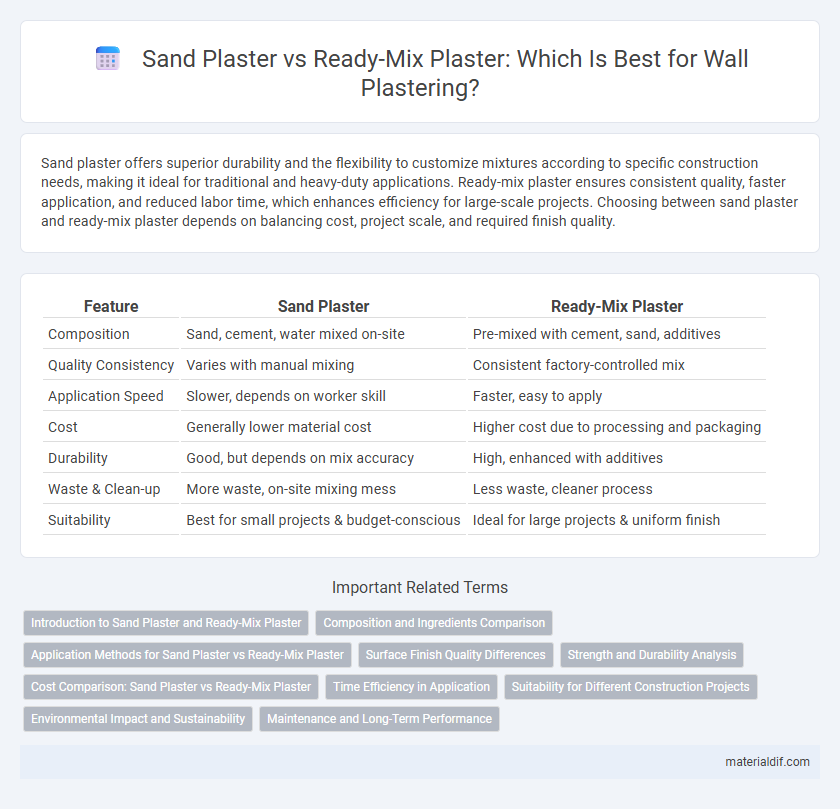

| Feature | Sand Plaster | Ready-Mix Plaster |

|---|---|---|

| Composition | Sand, cement, water mixed on-site | Pre-mixed with cement, sand, additives |

| Quality Consistency | Varies with manual mixing | Consistent factory-controlled mix |

| Application Speed | Slower, depends on worker skill | Faster, easy to apply |

| Cost | Generally lower material cost | Higher cost due to processing and packaging |

| Durability | Good, but depends on mix accuracy | High, enhanced with additives |

| Waste & Clean-up | More waste, on-site mixing mess | Less waste, cleaner process |

| Suitability | Best for small projects & budget-conscious | Ideal for large projects & uniform finish |

Introduction to Sand Plaster and Ready-Mix Plaster

Sand plaster involves a traditional mixture of sand, cement, and water, offering strong adhesion and durability for walls and ceilings. Ready-mix plaster, pre-mixed and packaged for convenience, ensures consistent quality and faster application with reduced labor costs. Both types cater to specific construction needs, balancing performance and ease of use.

Composition and Ingredients Comparison

Sand plaster primarily consists of sand, cement, and water, creating a textured and durable surface ideal for traditional masonry work. Ready-mix plaster includes pre-blended ingredients such as gypsum, lime, cement, and additives, ensuring consistent quality and faster application. The key difference lies in sand plaster's reliance on natural aggregates versus ready-mix's engineered components designed to enhance workability and finish.

Application Methods for Sand Plaster vs Ready-Mix Plaster

Sand plaster requires manual mixing and application using trowels, demanding skilled labor to achieve a smooth, even finish, whereas ready-mix plaster comes pre-mixed in bags, enabling quicker and more consistent application with minimal preparation. Sand plaster's water-to-material ratio must be adjusted on-site to suit the environment, while ready-mix plaster ensures factory-controlled consistency for easier workability and reduced cracking. Application of sand plaster often involves multiple coats with drying time between layers, whereas ready-mix plaster can be applied in fewer coats due to its optimized formulation.

Surface Finish Quality Differences

Sand plaster offers a coarser and more textured surface finish, making it suitable for rougher walls and providing better adhesion for paint or other coatings. Ready-mix plaster delivers a smoother, more consistent surface finish due to its uniform composition and fine aggregates, enhancing aesthetic appeal and reducing the need for additional surface preparation. The choice impacts overall durability and visual uniformity, with ready-mix plaster often preferred for interiors where a high-quality finish is essential.

Strength and Durability Analysis

Sand plaster offers superior strength and durability due to its customizable sand-cement ratio, allowing for tailored mix consistency that enhances bonding and longevity. Ready-mix plaster provides consistent quality and reduced application time but may exhibit reduced strength compared to traditional sand plaster if not properly mixed or applied. The choice between sand plaster and ready-mix plaster significantly impacts the structural integrity and lifespan of plastered surfaces in construction projects.

Cost Comparison: Sand Plaster vs Ready-Mix Plaster

Sand plaster costs significantly less than ready-mix plaster due to its raw material availability and minimal processing requirements. Ready-mix plaster, being pre-mixed in factories, involves higher transportation and packaging expenses that increase the overall price. For budget-sensitive construction projects, sand plaster provides a more economical solution without compromising basic finishing quality.

Time Efficiency in Application

Sand plaster requires onsite mixing, which can slow down the application process due to the need for precise measurement and consistency checks. Ready-mix plaster offers faster application as it comes pre-mixed, reducing preparation time and minimizing labor efforts on site. Construction projects benefit from ready-mix plaster's time efficiency, enabling quicker wall finishing and earlier project completion.

Suitability for Different Construction Projects

Sand plaster offers excellent breathability and is highly suitable for traditional or restoration projects where moisture control and natural materials are prioritized. Ready-mix plaster provides consistent quality and faster application, making it ideal for large-scale commercial or residential buildings requiring efficiency and uniformity. Choosing between sand plaster and ready-mix plaster depends on project scale, environmental conditions, and specific architectural requirements.

Environmental Impact and Sustainability

Sand plaster uses natural aggregates with minimal processing, resulting in lower carbon emissions and reduced environmental footprint compared to ready-mix plaster. Ready-mix plaster typically contains synthetic additives and requires energy-intensive production, contributing to higher greenhouse gas emissions. Choosing sand plaster promotes sustainability by utilizing locally sourced materials and reducing transportation-related pollution.

Maintenance and Long-Term Performance

Sand plaster requires regular maintenance to prevent cracks and erosion due to its porous nature, demanding periodic sealing and patching for long-term durability. Ready-mix plaster offers superior consistency and enhanced resistance to weathering, minimizing maintenance needs and ensuring long-lasting structural integrity. The use of additives in ready-mix formulations improves adhesion and flexibility, contributing to better performance over time compared to traditional sand plaster.

Sand Plaster vs Ready-Mix Plaster Infographic

materialdif.com

materialdif.com