Plaster skim coat creates a smooth, polished finish ideal for final wall surfaces, while plaster undercoat serves as a rough base layer that provides strength and adhesion for subsequent coats. The undercoat typically contains coarser aggregates for better keying, whereas the skim coat is finer and applied thinly to even out imperfections. Choosing the right coat depends on the desired texture and surface durability for your plastering project.

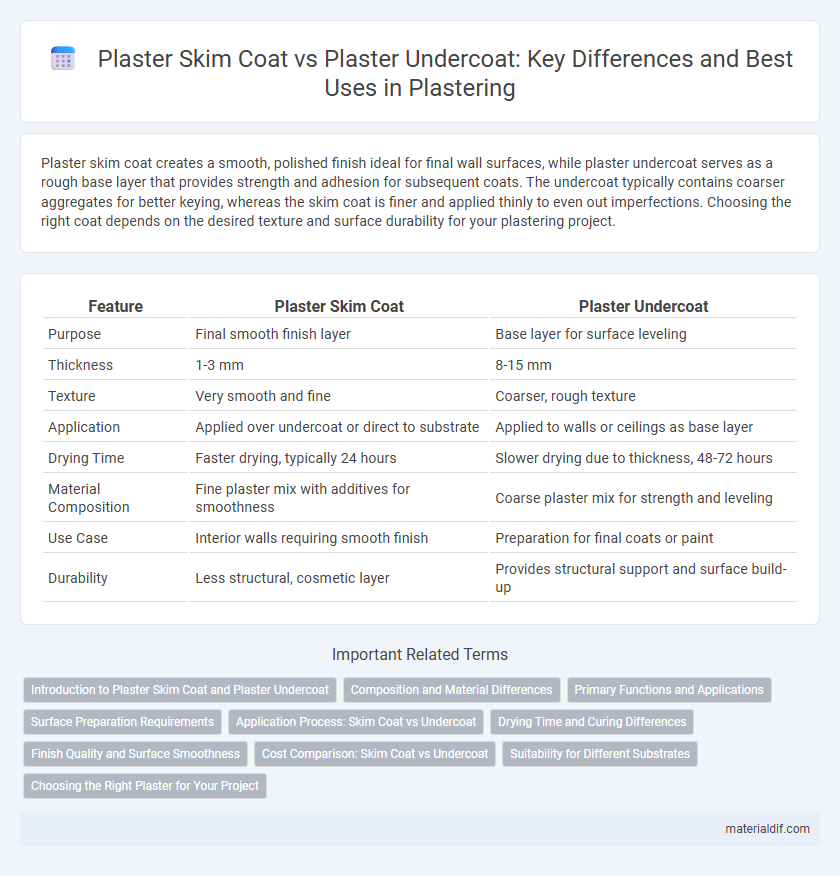

Table of Comparison

| Feature | Plaster Skim Coat | Plaster Undercoat |

|---|---|---|

| Purpose | Final smooth finish layer | Base layer for surface leveling |

| Thickness | 1-3 mm | 8-15 mm |

| Texture | Very smooth and fine | Coarser, rough texture |

| Application | Applied over undercoat or direct to substrate | Applied to walls or ceilings as base layer |

| Drying Time | Faster drying, typically 24 hours | Slower drying due to thickness, 48-72 hours |

| Material Composition | Fine plaster mix with additives for smoothness | Coarse plaster mix for strength and leveling |

| Use Case | Interior walls requiring smooth finish | Preparation for final coats or paint |

| Durability | Less structural, cosmetic layer | Provides structural support and surface build-up |

Introduction to Plaster Skim Coat and Plaster Undercoat

Plaster skim coat is a thin, smooth layer applied to walls and ceilings to create a flawless surface, ideal for final decoration and painting. Plaster undercoat serves as a thicker base layer that provides structural support and evens out rough surfaces before the skim coat is applied. Both layers work together to ensure durability and a polished finish in plastering projects.

Composition and Material Differences

Plaster skim coat consists primarily of fine materials such as gypsum or lime combined with fine sand, creating a smooth, thin finishing layer designed for surface refinement. The plaster undercoat contains coarser aggregates like larger sand grains mixed with gypsum or cement, providing a thicker, more durable base layer that enhances adhesion and structural strength. These material differences directly impact their application, with the undercoat focusing on build and support while the skim coat emphasizes a flawless, polished finish.

Primary Functions and Applications

Plaster skim coat serves as a smooth, finishing layer designed to create an even surface ready for painting or wallpapering, primarily used for aesthetic enhancement and surface refinement. Plaster undercoat, in contrast, acts as a foundational layer that provides strength and adhesion, applied to rough or uneven surfaces to build up thickness and ensure durability. Both layers are essential in plastering, with the undercoat focusing on structural support and the skim coat on final surface quality.

Surface Preparation Requirements

Plaster skim coat requires a thoroughly clean, dry, and smooth surface, free from dust, grease, and loose materials to ensure proper adhesion and a flawless finish. Plaster undercoat surfaces must be roughened or scored to provide a mechanical key for the subsequent plaster layers, enhancing grip and structural integrity. Both coats benefit from pre-wetting the substrate to prevent rapid water absorption that can cause cracking or poor bonding.

Application Process: Skim Coat vs Undercoat

Plaster skim coat involves applying a thin, smooth layer of plaster to refine wall surfaces, enhancing texture and preparing for painting or wallpaper. The undercoat is a thicker, rougher base layer applied directly onto substrates to level out major imperfections and provide a strong foundation for the skim coat. Skim coat requires careful troweling techniques for an even finish, while undercoat demands robust application to ensure structural adhesion and durability.

Drying Time and Curing Differences

Plaster skim coat typically dries faster, often within 24 hours, while plaster undercoat requires a longer drying time, ranging from 3 to 7 days due to its thicker application. The curing process for the undercoat is more extended, allowing for gradual moisture evaporation and better adhesion for subsequent layers. Skim coat's rapid drying supports fine finishing, whereas undercoat's slower cure provides a stable, solid base for plasterwork.

Finish Quality and Surface Smoothness

Plaster skim coat provides a finer finish quality with superior surface smoothness compared to plaster undercoat, making it ideal for final wall preparation before painting or wallpapering. The skim coat consists of a thin layer of fine plaster that fills minor imperfections, resulting in a polished, even surface. In contrast, the plaster undercoat is a thicker, rougher base layer designed primarily for leveling but requires a skim coat to achieve a smooth finish.

Cost Comparison: Skim Coat vs Undercoat

Plaster skim coat generally costs more per square meter than plaster undercoat due to its finer finish and thinner application layer, requiring more skilled labor. Undercoat plaster is typically thicker, designed to level uneven surfaces, and involves less material refinement, reducing overall expenses. Choosing between skim coat and undercoat depends on budget constraints and the desired smoothness of the final wall surface.

Suitability for Different Substrates

Plaster skim coat is highly suitable for smooth, finished surfaces such as drywall or existing plaster, providing a fine, polished finish ideal for painting or wallpapering. Plaster undercoat, designed for rougher substrates like masonry, brick, or concrete blocks, offers a thicker, more durable base layer that enhances adhesion and structural integrity. Selecting the appropriate coat based on substrate type ensures optimal durability, surface appearance, and long-term performance in interior wall applications.

Choosing the Right Plaster for Your Project

Plaster skim coat provides a smooth, fine finish ideal for final wall surfaces, enhancing paint adhesion and visual appeal. Plaster undercoat offers a thicker base layer that strengthens walls and fills imperfections, ensuring structural stability before the skim coat is applied. Selecting the right plaster depends on the project stage, with undercoat used for foundational layers and skim coat for a polished, decorative finish.

Plaster Skim Coat vs Plaster Undercoat Infographic

materialdif.com

materialdif.com