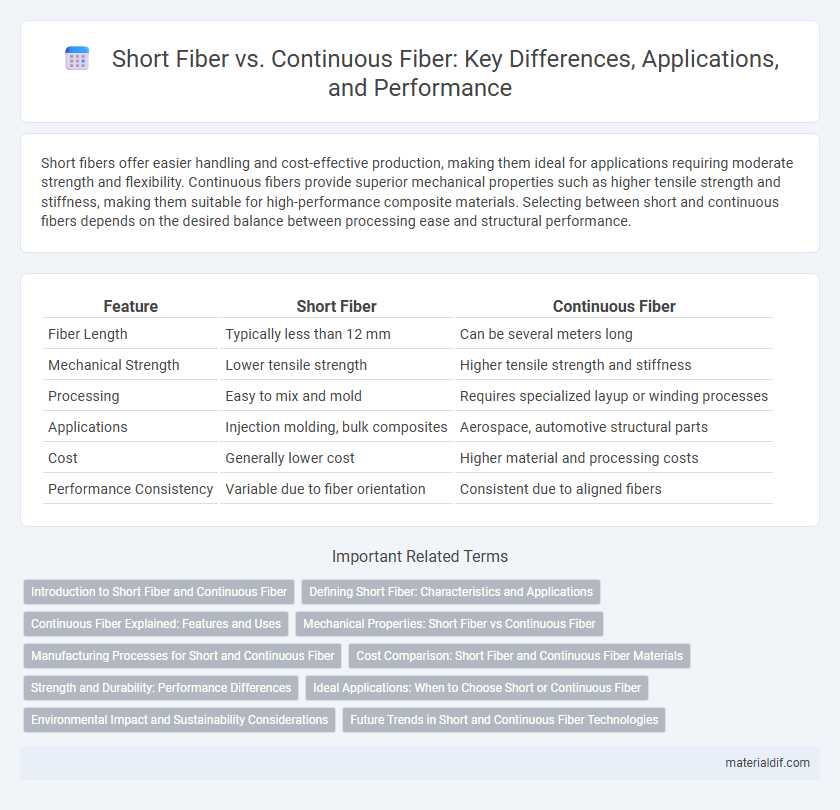

Short fibers offer easier handling and cost-effective production, making them ideal for applications requiring moderate strength and flexibility. Continuous fibers provide superior mechanical properties such as higher tensile strength and stiffness, making them suitable for high-performance composite materials. Selecting between short and continuous fibers depends on the desired balance between processing ease and structural performance.

Table of Comparison

| Feature | Short Fiber | Continuous Fiber |

|---|---|---|

| Fiber Length | Typically less than 12 mm | Can be several meters long |

| Mechanical Strength | Lower tensile strength | Higher tensile strength and stiffness |

| Processing | Easy to mix and mold | Requires specialized layup or winding processes |

| Applications | Injection molding, bulk composites | Aerospace, automotive structural parts |

| Cost | Generally lower cost | Higher material and processing costs |

| Performance Consistency | Variable due to fiber orientation | Consistent due to aligned fibers |

Introduction to Short Fiber and Continuous Fiber

Short fibers typically measure less than a few millimeters in length and are commonly used in composite materials to enhance mechanical properties such as impact resistance and toughness. Continuous fibers, in contrast, are long, unbroken strands that provide superior strength and stiffness, making them ideal for load-bearing applications in aerospace, automotive, and construction industries. The choice between short and continuous fiber depends on specific performance requirements, manufacturing processes, and cost considerations.

Defining Short Fiber: Characteristics and Applications

Short fiber consists of fibers with lengths typically less than 25 mm, characterized by ease of processing and good dispersion within a matrix. These fibers enhance mechanical properties such as tensile strength and impact resistance in composites used in automotive parts, consumer goods, and construction materials. Applications of short fibers are favored for cost-effectiveness and versatility in injection molding and extrusion processes.

Continuous Fiber Explained: Features and Uses

Continuous fiber consists of long, uninterrupted strands that provide superior tensile strength and flexibility compared to short fibers, making them ideal for high-performance composite materials. These fibers allow for better load distribution and enhanced mechanical properties in applications such as aerospace, automotive parts, and sporting goods. The ability to be woven into fabric or aligned precisely within a resin matrix makes continuous fibers essential for manufacturing lightweight, durable, and impact-resistant structures.

Mechanical Properties: Short Fiber vs Continuous Fiber

Continuous fibers exhibit superior mechanical properties compared to short fibers due to their uninterrupted length, which enhances tensile strength, stiffness, and load transfer efficiency in composite materials. Short fibers provide improved toughness and impact resistance but generally result in lower overall strength and modulus because of fiber-end stress concentration and reduced load-bearing capability. The choice between short and continuous fibers depends on balancing mechanical performance requirements with manufacturing complexity and cost-effectiveness in applications like aerospace, automotive, and sports equipment.

Manufacturing Processes for Short and Continuous Fiber

Short fiber manufacturing processes typically involve chopping or cutting fiber strands into shorter lengths, which are then dispersed within a polymer matrix using extrusion, injection molding, or compression molding techniques. Continuous fiber production requires precise alignment and impregnation of fibers during processes such as filament winding, pultrusion, or automated fiber placement to achieve high strength and structural integrity. Differences in manufacturing impact material properties, with short fiber composites offering ease of processing and cost-effectiveness, while continuous fiber composites provide superior mechanical performance and tailored reinforcement.

Cost Comparison: Short Fiber and Continuous Fiber Materials

Short fiber materials generally incur lower upfront costs due to simpler manufacturing processes and less stringent quality requirements, making them cost-effective for mass production. Continuous fiber materials, while more expensive initially because of advanced production techniques and higher raw material quality, provide superior mechanical properties that can reduce overall lifecycle costs in high-performance applications. The choice between short and continuous fiber often depends on the balance between cost constraints and performance demands specific to the intended use.

Strength and Durability: Performance Differences

Continuous fibers exhibit superior strength and durability compared to short fibers due to their uninterrupted length, which enables efficient load transfer and reduces weak points. Short fibers, while easier to process and more cost-effective, often result in composites with lower tensile strength and increased susceptibility to fatigue and wear. The mechanical performance of continuous fiber composites makes them ideal for high-stress applications requiring long-term reliability and enhanced structural integrity.

Ideal Applications: When to Choose Short or Continuous Fiber

Short fibers provide enhanced impact resistance and are ideal for injection molding of small, complex parts where isotropic properties are sufficient. Continuous fibers offer superior tensile strength and stiffness, making them preferable for structural components in aerospace, automotive, and sporting goods. Selecting between short and continuous fiber depends on the balance between mechanical performance requirements and manufacturing complexity.

Environmental Impact and Sustainability Considerations

Short fiber composites often have a lower environmental impact due to reduced energy consumption during manufacturing and easier recyclability compared to continuous fiber composites. Continuous fiber materials provide superior strength and durability, potentially extending product life and minimizing resource use over time, contributing to sustainability. Selecting between short and continuous fibers depends on balancing environmental footprint, performance requirements, and end-of-life material recovery.

Future Trends in Short and Continuous Fiber Technologies

Advancements in short fiber technology are focusing on improving dispersion techniques and enhancing matrix-fiber bonding to boost mechanical properties in composite materials. Continuous fiber technologies are evolving toward automated manufacturing processes and integration with smart materials, enabling higher strength-to-weight ratios and real-time structural health monitoring. The future of both fiber types involves hybridization strategies to optimize performance for aerospace, automotive, and renewable energy applications.

Short Fiber vs Continuous Fiber Infographic

materialdif.com

materialdif.com