Polylactic acid (PLA) fiber, derived from renewable resources like corn starch, offers superior biodegradability and lower environmental impact compared to polypropylene fiber, which is petroleum-based and non-biodegradable. PLA fibers provide excellent moisture-wicking and breathability, making them ideal for sustainable textile applications, whereas polypropylene fibers excel in strength and chemical resistance but contribute to long-term plastic pollution. Choosing PLA fibers supports eco-friendly manufacturing and reduces reliance on fossil fuels, aligning with increasing demand for sustainable materials in the fiber industry.

Table of Comparison

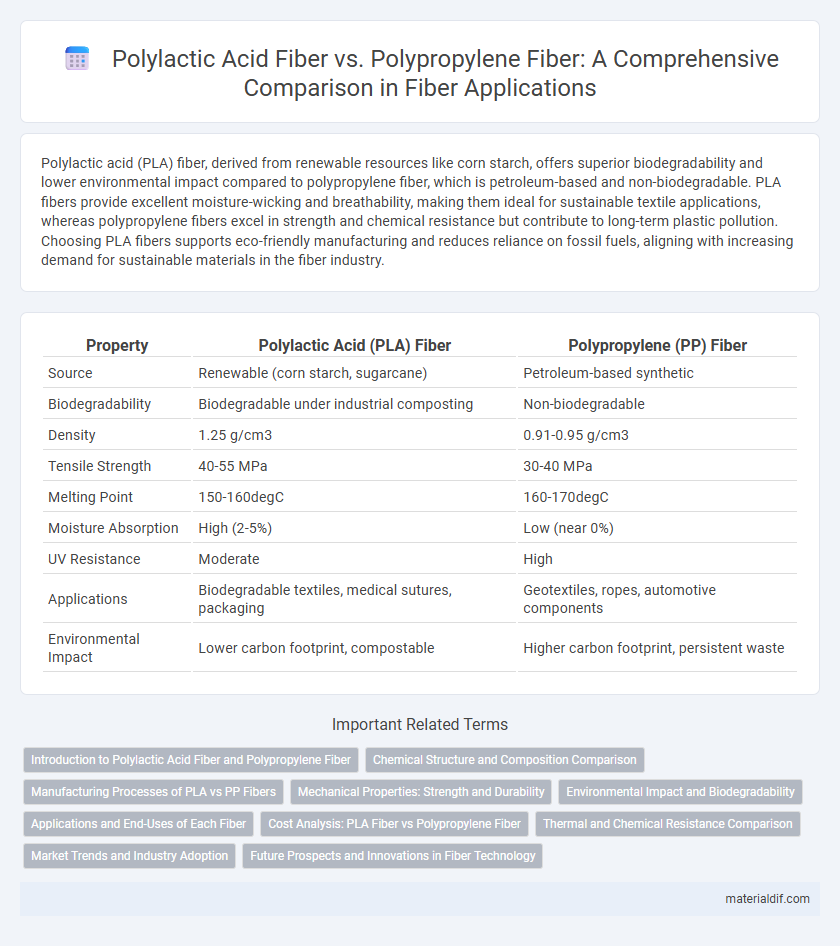

| Property | Polylactic Acid (PLA) Fiber | Polypropylene (PP) Fiber |

|---|---|---|

| Source | Renewable (corn starch, sugarcane) | Petroleum-based synthetic |

| Biodegradability | Biodegradable under industrial composting | Non-biodegradable |

| Density | 1.25 g/cm3 | 0.91-0.95 g/cm3 |

| Tensile Strength | 40-55 MPa | 30-40 MPa |

| Melting Point | 150-160degC | 160-170degC |

| Moisture Absorption | High (2-5%) | Low (near 0%) |

| UV Resistance | Moderate | High |

| Applications | Biodegradable textiles, medical sutures, packaging | Geotextiles, ropes, automotive components |

| Environmental Impact | Lower carbon footprint, compostable | Higher carbon footprint, persistent waste |

Introduction to Polylactic Acid Fiber and Polypropylene Fiber

Polylactic acid (PLA) fiber is a biodegradable, bio-based polymer derived from renewable resources such as corn starch or sugarcane, offering eco-friendly alternatives in textile and packaging industries. Polypropylene fiber, a synthetic polymer made from petroleum, is known for its durability, chemical resistance, and hydrophobic properties, widely used in automotive fabrics, geotextiles, and industrial applications. Both fibers exhibit distinct performance characteristics, with PLA fiber emphasizing sustainability and biodegradability, while polypropylene fiber prioritizes strength and chemical stability.

Chemical Structure and Composition Comparison

Polylactic acid (PLA) fiber is composed of biodegradable aliphatic polyester derived from renewable resources like corn starch, consisting primarily of repeating lactic acid units, which impart hydrophilicity and enhanced biodegradability. Polypropylene (PP) fiber, on the other hand, is a synthetic polyolefin polymer made from propylene monomers, characterized by a nonpolar hydrocarbon chain that provides hydrophobicity and exceptional chemical resistance. The chemical structure of PLA includes ester functional groups that influence its mechanical properties and degradation behavior, whereas PP's saturated hydrocarbon backbone offers superior thermal stability and resilience but lacks biodegradability.

Manufacturing Processes of PLA vs PP Fibers

Polylactic Acid (PLA) fiber production involves polymerization of lactic acid derived from renewable resources like corn starch through fermentation, followed by melt spinning or solution spinning to form fibers. Polypropylene (PP) fiber manufacturing utilizes petrochemical-derived polypropylene resin, which undergoes melt spinning at high temperatures to produce fibers known for their durability and chemical resistance. The PLA fiber process emphasizes biodegradability and bio-based sourcing, while PP fiber manufacturing focuses on cost-efficiency and mechanical performance.

Mechanical Properties: Strength and Durability

Polylactic Acid (PLA) fiber exhibits moderate tensile strength and biodegradability, making it suitable for eco-friendly applications but with lower durability under high-stress conditions compared to polypropylene fiber. Polypropylene fiber offers superior tensile strength, excellent chemical resistance, and long-term durability, ideal for heavy-duty uses such as concrete reinforcement and geotextiles. The higher resilience and mechanical robustness of polypropylene fiber outperform PLA fiber in demanding environments where strength retention and wear resistance are critical.

Environmental Impact and Biodegradability

Polylactic Acid (PLA) fiber offers a significant environmental advantage over Polypropylene (PP) fiber due to its biodegradability and origin from renewable resources like corn starch or sugarcane. PLA fiber decomposes naturally under industrial composting conditions, reducing landfill waste and microplastic pollution associated with non-biodegradable PP fiber, which is derived from fossil fuels. The lower carbon footprint and enhanced end-of-life sustainability make PLA fiber a preferable choice for eco-conscious textile and packaging industries.

Applications and End-Uses of Each Fiber

Polylactic acid (PLA) fiber is widely used in biomedical applications such as sutures, drug delivery systems, and tissue engineering due to its biodegradability and biocompatibility. Polypropylene (PP) fiber finds extensive use in construction for concrete reinforcement, geotextiles, and filtration products because of its high chemical resistance and durability. PLA fiber suits eco-friendly packaging and textile applications, while PP fiber excels in automotive parts and industrial carpeting.

Cost Analysis: PLA Fiber vs Polypropylene Fiber

Polylactic Acid (PLA) fiber typically has a higher production cost than polypropylene fiber due to its bio-based raw materials and more complex manufacturing processes. Polypropylene fiber remains cost-effective with lower material and energy expenses, making it a preferred choice for budget-sensitive applications. Despite its higher cost, PLA fiber offers sustainability benefits that may justify the investment in eco-conscious markets.

Thermal and Chemical Resistance Comparison

Polylactic acid (PLA) fiber exhibits lower thermal resistance with a melting point around 150-160degC, whereas polypropylene (PP) fiber withstands higher temperatures up to 160-170degC, making PP more suitable for applications requiring heat stability. Chemically, PLA fiber is biodegradable but sensitive to hydrolysis and acidic environments, while PP fiber demonstrates superior chemical resistance, especially against acids, alkalis, and organic solvents. The enhanced chemical and thermal resilience of polypropylene fiber makes it preferable for industrial uses demanding durability under harsh conditions.

Market Trends and Industry Adoption

Polylactic Acid (PLA) fiber is gaining significant traction in the sustainable textiles market due to its biodegradability and renewable sourcing, making it a preferred choice among eco-conscious brands. Polypropylene fiber remains dominant in applications requiring high durability and moisture resistance, such as geotextiles and industrial uses, but faces growing scrutiny over its environmental impact. Market adoption trends indicate a gradual shift as regulatory pressures and consumer demand drive increased investment in PLA fiber technologies and manufacturing scalability.

Future Prospects and Innovations in Fiber Technology

Polylactic Acid (PLA) fiber shows promising future prospects due to its biodegradability and renewable resource base, aligning with growing environmental sustainability trends in fiber technology. Innovations in PLA fiber focus on enhancing mechanical strength and thermal stability to expand its applications in textile and packaging industries. Polypropylene fiber remains competitive with ongoing advancements in composite materials and recycling processes aimed at improving durability and reducing environmental impact.

Polylactic Acid Fiber vs Polypropylene Fiber Infographic

materialdif.com

materialdif.com