Thermal bonding uses heat to fuse fibers, creating strong, uniform connections ideal for high-strength applications. Mechanical bonding relies on physical entanglement or needle punching, offering flexibility and enhanced texture but generally lower tensile strength. Choosing between thermal and mechanical bonding depends on the desired balance of durability, texture, and processing costs in fiber products.

Table of Comparison

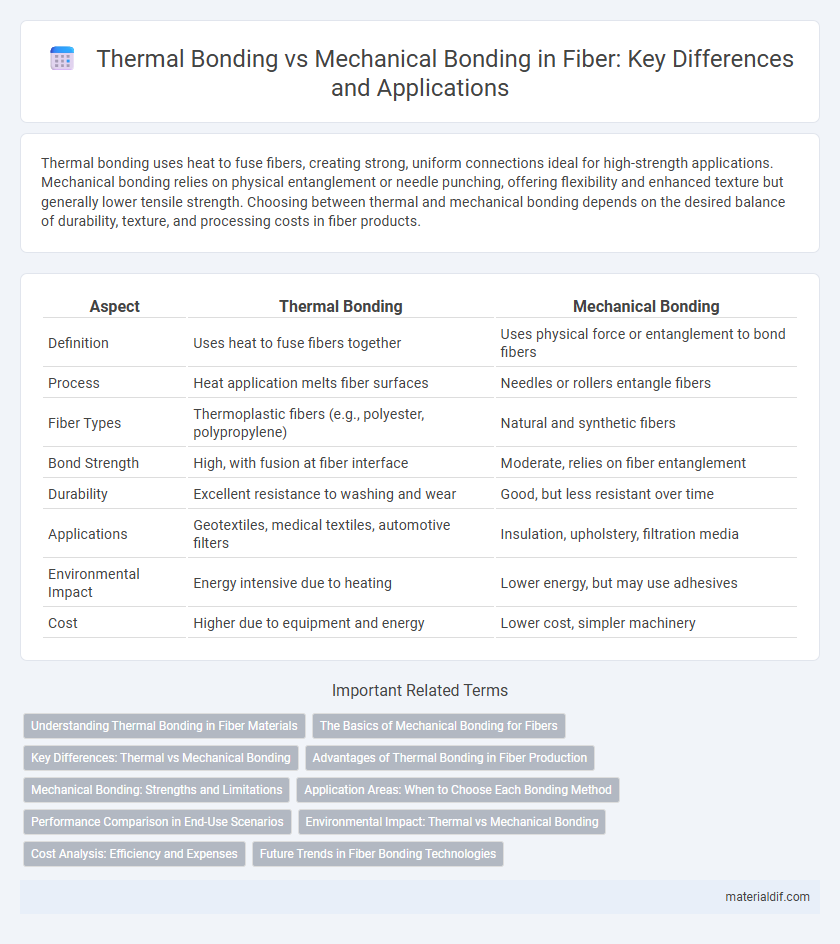

| Aspect | Thermal Bonding | Mechanical Bonding |

|---|---|---|

| Definition | Uses heat to fuse fibers together | Uses physical force or entanglement to bond fibers |

| Process | Heat application melts fiber surfaces | Needles or rollers entangle fibers |

| Fiber Types | Thermoplastic fibers (e.g., polyester, polypropylene) | Natural and synthetic fibers |

| Bond Strength | High, with fusion at fiber interface | Moderate, relies on fiber entanglement |

| Durability | Excellent resistance to washing and wear | Good, but less resistant over time |

| Applications | Geotextiles, medical textiles, automotive filters | Insulation, upholstery, filtration media |

| Environmental Impact | Energy intensive due to heating | Lower energy, but may use adhesives |

| Cost | Higher due to equipment and energy | Lower cost, simpler machinery |

Understanding Thermal Bonding in Fiber Materials

Thermal bonding in fiber materials involves using heat to fuse fibers together, creating a strong, continuous fabric without the need for adhesives or sewing. This process enhances durability and improves resistance to moisture and chemicals compared to mechanical bonding methods, which rely on needle punching or stitching. Understanding thermal bonding is crucial for selecting materials in applications requiring high strength, uniformity, and thermal stability.

The Basics of Mechanical Bonding for Fibers

Mechanical bonding in fibers involves physically interlocking fibers through entanglement or needle punching, creating a nonwoven fabric structure without the need for heat or adhesives. This technique enhances fabric strength, durability, and texture while maintaining breathability, making it ideal for applications like filtration, geotextiles, and upholstery. Unlike thermal bonding, mechanical bonding preserves the inherent properties of fibers, allowing for more versatile and flexible fabric designs.

Key Differences: Thermal vs Mechanical Bonding

Thermal bonding fuses fibers using heat, resulting in a seamless, durable connection ideal for synthetic materials like polyester. Mechanical bonding relies on physical entanglement or needle punching, creating strong, flexible webs often used in nonwoven fabrics such as geotextiles. Key differences include thermal bonding's dependency on heat and melting points, while mechanical bonding emphasizes fiber entanglement without altering fiber chemical properties.

Advantages of Thermal Bonding in Fiber Production

Thermal bonding in fiber production offers superior strength and durability by fusing fibers at the molecular level, resulting in enhanced fabric stability and longevity. This method reduces the use of adhesives or chemicals, promoting eco-friendly manufacturing processes and improving fabric breathability. Improved fiber alignment and bonding consistency achieved through thermal bonding lead to better softness and flexibility in the final textile products.

Mechanical Bonding: Strengths and Limitations

Mechanical bonding in fiber manufacturing offers improved flexibility and durability by physically intertwining fibers, enhancing resistance to tension and shear stress. Its main strength lies in retaining the original fiber properties without altering chemical structures, making it ideal for applications requiring high tensile strength and elasticity. However, mechanical bonding can have limitations such as potential fiber slippage and reduced uniformity compared to thermal bonding, which uses heat to fuse fibers at a molecular level.

Application Areas: When to Choose Each Bonding Method

Thermal bonding is ideal for applications requiring high strength and durability, such as automotive filters, geotextiles, and medical fabrics, where heat-resistant and stable fibers are essential. Mechanical bonding suits products demanding flexibility and softness, including carpets, upholstery, and nonwoven wipes, benefiting from entanglement without fiber damage. Selecting between thermal and mechanical bonding depends on the end-use requirements for strength, texture, and thermal stability in fiber-based materials.

Performance Comparison in End-Use Scenarios

Thermal bonding in fibers offers superior durability and resistance to wear under high-temperature applications, making it ideal for automotive and industrial textiles where heat exposure is frequent. Mechanical bonding, while providing excellent bulk and flexibility, excels in upholstery and mattress manufacturing where cushioning and softness are prioritized. Performance evaluations highlight that thermal bonding enhances tensile strength and dimensional stability, whereas mechanical bonding improves air permeability and comfort in end-use scenarios.

Environmental Impact: Thermal vs Mechanical Bonding

Thermal bonding in fiber production consumes significant energy due to high-temperature processes, leading to a larger carbon footprint compared to mechanical bonding. Mechanical bonding uses physical entanglement without heat, reducing energy consumption and minimizing greenhouse gas emissions. This energy efficiency makes mechanical bonding a more environmentally sustainable choice for fiber manufacturing.

Cost Analysis: Efficiency and Expenses

Thermal bonding offers lower operational costs by reducing energy consumption and eliminating the need for adhesives compared to mechanical bonding, which incurs higher expenses due to additional components and maintenance. Efficiency in thermal bonding comes from faster production speeds and less material waste, whereas mechanical bonding demands more labor and tool wear replacement. Overall, thermal bonding presents a cost-effective solution for large-scale fiber production, minimizing total expenditure while maximizing throughput.

Future Trends in Fiber Bonding Technologies

Future trends in fiber bonding technologies show a clear shift towards thermal bonding due to its superior energy efficiency and enhanced bond strength compared to mechanical bonding. Advances in nanoscale thermal bonding methods are enabling more precise control over fiber alignment and reduced material stress, which is critical for applications in high-performance textiles and composite materials. Emerging hybrid techniques that combine thermal and mechanical processes aim to optimize durability and flexibility, meeting the growing demand for sustainable and lightweight fiber products.

Thermal Bonding vs Mechanical Bonding Infographic

materialdif.com

materialdif.com