Hemp fiber is known for its strength and durability, making it ideal for heavy-duty textiles and industrial applications, while flax fiber offers a softer texture suitable for fine linen and apparel. Hemp grows faster and requires fewer pesticides than flax, contributing to its sustainability advantages. Both fibers are biodegradable and eco-friendly, but hemp's resilience and moisture-wicking properties make it increasingly popular in sustainable fashion and home textiles.

Table of Comparison

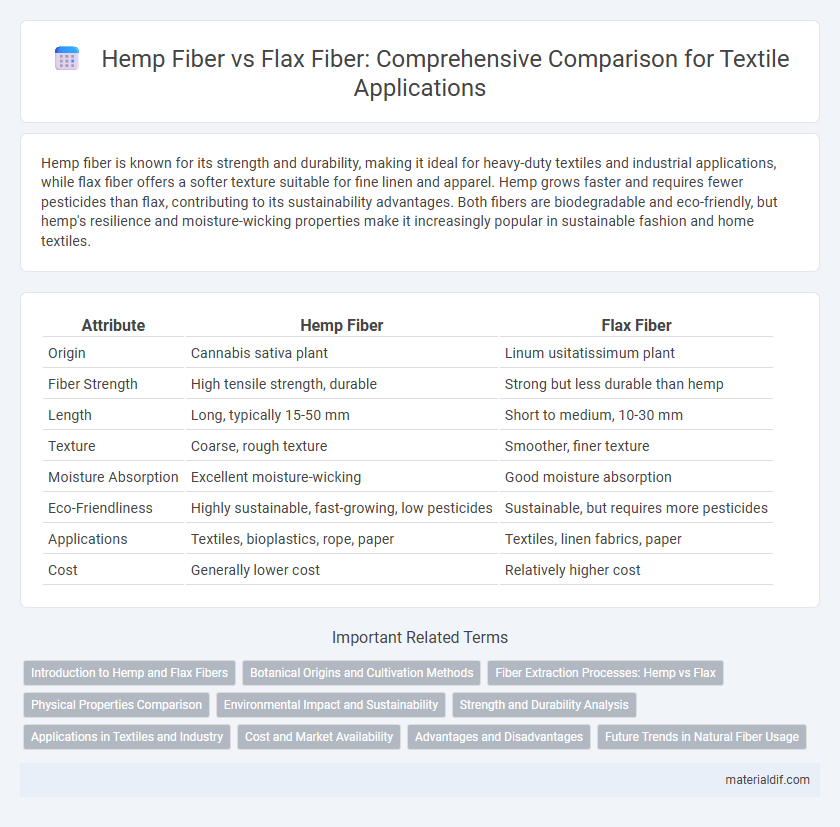

| Attribute | Hemp Fiber | Flax Fiber |

|---|---|---|

| Origin | Cannabis sativa plant | Linum usitatissimum plant |

| Fiber Strength | High tensile strength, durable | Strong but less durable than hemp |

| Length | Long, typically 15-50 mm | Short to medium, 10-30 mm |

| Texture | Coarse, rough texture | Smoother, finer texture |

| Moisture Absorption | Excellent moisture-wicking | Good moisture absorption |

| Eco-Friendliness | Highly sustainable, fast-growing, low pesticides | Sustainable, but requires more pesticides |

| Applications | Textiles, bioplastics, rope, paper | Textiles, linen fabrics, paper |

| Cost | Generally lower cost | Relatively higher cost |

Introduction to Hemp and Flax Fibers

Hemp fiber, derived from the stalks of the Cannabis sativa plant, is renowned for its strength, durability, and resistance to pests, making it a sustainable choice for textiles and industrial applications. Flax fiber, extracted from the stems of the Linum usitatissimum plant, is valued for its smooth texture and natural luster, commonly used in linen production. Both fibers are biodegradable, eco-friendly, and have low water and pesticide requirements compared to conventional cotton.

Botanical Origins and Cultivation Methods

Hemp fiber originates from the Cannabis sativa plant, known for its rapid growth and adaptability to various soil types, often cultivated with minimal pesticides and requiring less water compared to conventional crops. Flax fiber is derived from the Linum usitatissimum plant, thriving in cooler, temperate climates with well-drained soil, and typically demands more intensive soil preparation and pest management to ensure high-quality fiber production. Both fibers are extracted through retting processes, but hemp's robust stalk structure allows for potentially higher yield per acre under sustainable farming practices.

Fiber Extraction Processes: Hemp vs Flax

Hemp fiber extraction involves a process called retting, where microbial activity breaks down the pectins binding the fibers, typically using water or dew retting methods that can take several days to weeks. Flax fiber extraction also utilizes retting, with water retting being common, but the process is often shorter and requires more precise control to prevent fiber damage, followed by scutching to separate the fibers. Both fibers undergo decortication to remove the woody core, but hemp's tougher stalk requires more intensive mechanical processing compared to the finer flax fibers.

Physical Properties Comparison

Hemp fiber exhibits greater tensile strength and durability than flax fiber, making it ideal for heavy-duty textile applications. Flax fiber offers superior softness and flexibility, which enhances comfort in clothing and finer fabrics. Both fibers have similar moisture-wicking properties, but hemp tends to be more resistant to UV light and microbial degradation.

Environmental Impact and Sustainability

Hemp fiber requires significantly less water and pesticides compared to flax fiber, making it a more environmentally sustainable choice. Hemp also has a faster growth cycle, absorbing more CO2 per hectare, which enhances its carbon sequestration benefits. Flax fiber production can lead to soil degradation without proper crop rotation, whereas hemp improves soil health by replenishing nutrients.

Strength and Durability Analysis

Hemp fiber exhibits superior tensile strength compared to flax fiber, making it one of the strongest natural fibers available with a tensile strength averaging around 690 MPa. Its durability is enhanced by a higher lignin content, which provides resistance to microbial degradation and extends its lifespan in various environmental conditions. Flax fiber, while less strong at approximately 500 MPa tensile strength, offers good durability but tends to break down faster than hemp when exposed to moisture and UV light.

Applications in Textiles and Industry

Hemp fiber exhibits superior strength and durability compared to flax fiber, making it ideal for industrial textiles such as ropes, canvases, and geotextiles, while flax fiber is preferred for fine linens and apparel due to its softness and luster. Hemp's resistance to mold and UV radiation extends its use in outdoor applications, whereas flax's moisture-wicking properties enhance comfort in clothing. Both fibers are biodegradable and renewable, with hemp offering faster growth cycles, supporting sustainable production in textile and industrial sectors.

Cost and Market Availability

Hemp fiber typically costs more than flax fiber due to higher processing requirements and less developed supply chains, but it benefits from increasing consumer demand driven by sustainability trends. Flax fiber remains more affordable and widely available, supported by well-established markets in Europe and North America. Market availability for hemp fiber is expanding as regulations ease and production scales up, while flax maintains its dominance in traditional textile and composite industries.

Advantages and Disadvantages

Hemp fiber offers superior tensile strength and faster growth cycles compared to flax fiber, making it highly sustainable and cost-effective for industrial applications. However, hemp fibers tend to be coarser and require more extensive processing to achieve similar softness and fineness as flax fibers, which are traditionally favored for lightweight and delicate textiles. Flax fiber excels in breathability and moisture-wicking properties but has a slower cultivation period and generally lower yield per acre compared to hemp.

Future Trends in Natural Fiber Usage

Hemp fiber is expected to dominate future natural fiber markets due to its superior tensile strength, faster growth cycles, and higher sustainability compared to flax fiber. Innovations in bio-composite materials and eco-friendly textiles are accelerating demand for hemp, which offers enhanced durability and biodegradability. Market analysts predict hemp fiber's integration into automotive, construction, and fashion industries will outpace flax, driven by global environmental regulations and consumer preference for green products.

Hemp fiber vs Flax fiber Infographic

materialdif.com

materialdif.com