Nylon fiber offers superior strength, elasticity, and resistance to abrasion compared to rayon fiber, making it ideal for durable pet products like collars and leashes. Rayon fiber, derived from natural cellulose, provides a softer feel and better moisture absorption, which enhances comfort in pet bedding and clothing. Choosing between nylon and rayon fibers depends on whether durability or softness and breathability are prioritized in pet care items.

Table of Comparison

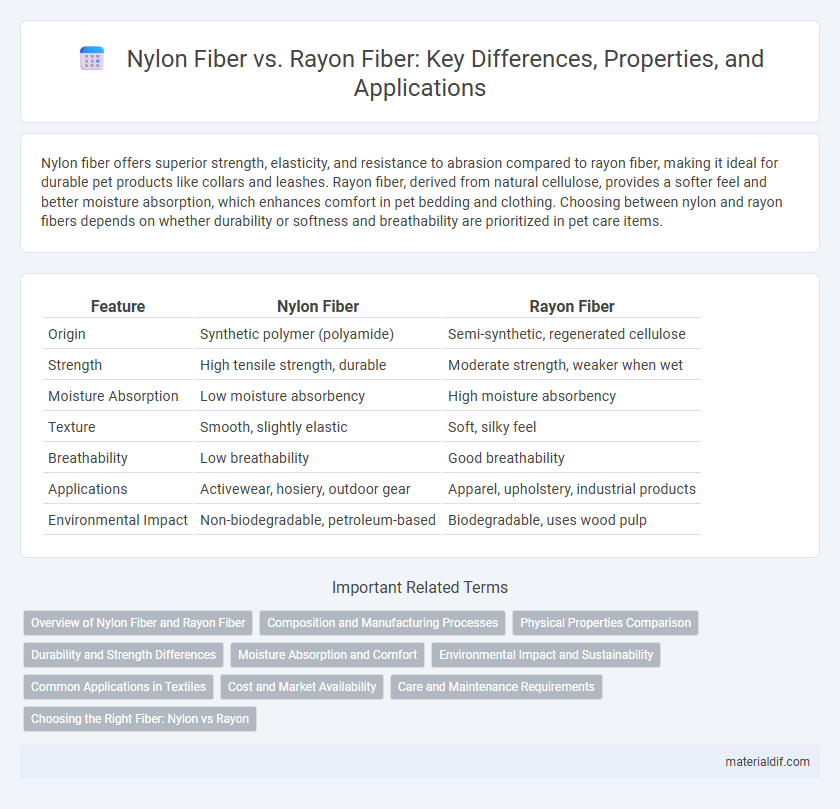

| Feature | Nylon Fiber | Rayon Fiber |

|---|---|---|

| Origin | Synthetic polymer (polyamide) | Semi-synthetic, regenerated cellulose |

| Strength | High tensile strength, durable | Moderate strength, weaker when wet |

| Moisture Absorption | Low moisture absorbency | High moisture absorbency |

| Texture | Smooth, slightly elastic | Soft, silky feel |

| Breathability | Low breathability | Good breathability |

| Applications | Activewear, hosiery, outdoor gear | Apparel, upholstery, industrial products |

| Environmental Impact | Non-biodegradable, petroleum-based | Biodegradable, uses wood pulp |

Overview of Nylon Fiber and Rayon Fiber

Nylon fiber, a synthetic polymer known for its exceptional strength, elasticity, and abrasion resistance, is widely used in textiles requiring durability and resilience, such as activewear and industrial applications. Rayon fiber, a semi-synthetic cellulose fiber derived from wood pulp, offers a soft, breathable, and highly absorbent alternative valued for its silk-like texture and comfort in apparel and home textiles. Both fibers exhibit distinct physical properties, with nylon excelling in durability and moisture resistance, while rayon stands out for its natural feel and versatility in fabric blends.

Composition and Manufacturing Processes

Nylon fiber is a synthetic polymer made from polyamide compounds through a polymerization process involving hexamethylene diamine and adipic acid, resulting in strong, elastic fibers commonly produced by melt spinning. Rayon fiber, a semi-synthetic fiber, is derived from natural cellulose sources such as wood pulp, processed chemically through viscose, cuprammonium, or lyocell methods, allowing for varied fiber properties. The manufacturing of nylon emphasizes petrochemical-based synthesis and thermal processing, whereas rayon involves regeneration of cellulose through chemical treatments, impacting their respective biodegradability and performance characteristics.

Physical Properties Comparison

Nylon fiber exhibits superior strength and elasticity compared to rayon fiber, making it more durable and resistant to abrasion. Rayon fiber, derived from cellulose, is softer and more absorbent but tends to wrinkle and has lower tensile strength. Nylon's high resilience and moisture resistance provide advantages in applications requiring durability, while rayon's breathability suits comfort-focused textiles.

Durability and Strength Differences

Nylon fiber exhibits superior durability and tensile strength compared to rayon fiber, making it ideal for applications requiring high resistance to abrasion and strain. Nylon's synthetic polymer structure provides enhanced elasticity and resilience, whereas rayon, a semi-synthetic cellulose fiber, tends to weaken when exposed to moisture and prolonged stress. This fundamental difference results in nylon being the preferred choice for demanding textiles like activewear and industrial fabrics, while rayon suits lightweight, breathable garments with less emphasis on strength.

Moisture Absorption and Comfort

Nylon fiber has low moisture absorption, typically absorbing less than 4% of its weight in water, which makes it less breathable and can cause discomfort in hot and humid conditions. Rayon fiber, on the other hand, absorbs moisture up to 12-14%, providing better breathability and enhanced comfort by wicking sweat away from the skin. This higher moisture absorption capacity of rayon makes it a preferred choice for lightweight, breathable fabrics in warm climates.

Environmental Impact and Sustainability

Nylon fiber, derived from petrochemicals, has a significant environmental footprint due to its non-biodegradable nature and energy-intensive manufacturing process, contributing to greenhouse gas emissions. Rayon fiber, made from regenerated cellulose typically sourced from wood pulp, presents biodegradability advantages but raises sustainability concerns related to deforestation and chemical-intensive production methods. Sustainable alternatives focus on closed-loop processing for rayon and bio-based nylons to reduce resource consumption and minimize ecological damage.

Common Applications in Textiles

Nylon fiber is commonly used in activewear, hosiery, and outdoor gear due to its high strength, elasticity, and abrasion resistance. Rayon fiber finds extensive application in apparel and home textiles, prized for its softness, breathability, and silky texture that mimics natural fibers. Both fibers serve distinct roles in textile manufacturing, with nylon favored for durability and rayon valued for comfort and drape.

Cost and Market Availability

Nylon fiber generally costs more than rayon fiber due to its synthetic production process involving petrochemicals, which leads to higher manufacturing expenses. Rayon fiber, derived from natural cellulose, offers a more affordable alternative and is widely available in textile markets globally due to its easy production from renewable resources. Nylon's premium pricing reflects its durability and strength, whereas rayon's lower cost and abundance make it popular for budget-friendly and versatile fabric applications.

Care and Maintenance Requirements

Nylon fiber requires low maintenance, being highly resistant to abrasion, mildew, and chemicals, and it dries quickly, making it ideal for activewear and outdoor use. Rayon fiber demands more delicate care, as it is prone to shrinking, stretching, and damage when exposed to water and heat, necessitating gentle hand washing or dry cleaning. Proper care of nylon extends its durability, while rayon's fragile nature requires careful handling to maintain its softness and appearance.

Choosing the Right Fiber: Nylon vs Rayon

Nylon fiber offers superior strength, elasticity, and moisture-wicking properties, making it ideal for activewear and durable textiles, while rayon fiber excels in breathability and softness, providing comfort for lightweight clothing and drapery. Nylon's synthetic composition enhances abrasion resistance and quick-drying capabilities, whereas rayon, derived from cellulose, delivers a silky texture but requires more delicate care. Selecting between nylon and rayon depends on priorities such as durability, moisture management, comfort, and maintenance requirements.

Nylon Fiber vs Rayon Fiber Infographic

materialdif.com

materialdif.com