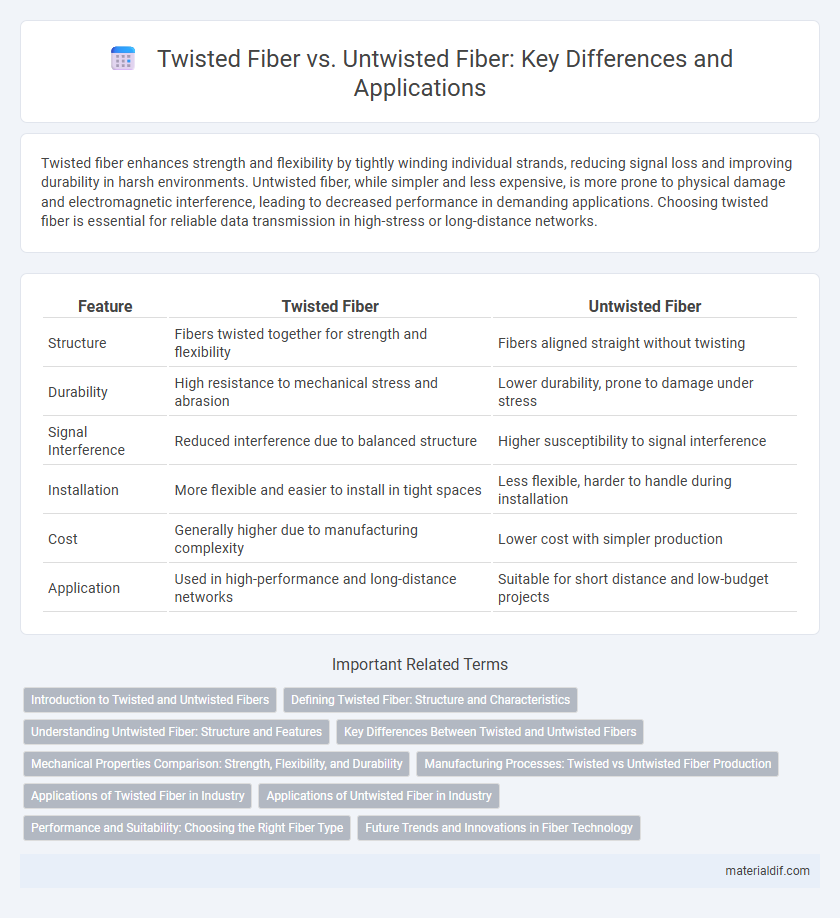

Twisted fiber enhances strength and flexibility by tightly winding individual strands, reducing signal loss and improving durability in harsh environments. Untwisted fiber, while simpler and less expensive, is more prone to physical damage and electromagnetic interference, leading to decreased performance in demanding applications. Choosing twisted fiber is essential for reliable data transmission in high-stress or long-distance networks.

Table of Comparison

| Feature | Twisted Fiber | Untwisted Fiber |

|---|---|---|

| Structure | Fibers twisted together for strength and flexibility | Fibers aligned straight without twisting |

| Durability | High resistance to mechanical stress and abrasion | Lower durability, prone to damage under stress |

| Signal Interference | Reduced interference due to balanced structure | Higher susceptibility to signal interference |

| Installation | More flexible and easier to install in tight spaces | Less flexible, harder to handle during installation |

| Cost | Generally higher due to manufacturing complexity | Lower cost with simpler production |

| Application | Used in high-performance and long-distance networks | Suitable for short distance and low-budget projects |

Introduction to Twisted and Untwisted Fibers

Twisted fiber involves strands that are helically wound together, enhancing flexibility and strength, making it ideal for telecommunications and high-tension applications. Untwisted fiber consists of parallel strands laid side by side without twisting, providing easier access for splicing and sensing but less mechanical durability. Understanding the structural differences helps optimize fiber choice for performance, durability, and installation processes in networking systems.

Defining Twisted Fiber: Structure and Characteristics

Twisted fiber consists of multiple individual strands tightly wound together in a helical pattern, enhancing its tensile strength and flexibility. This structure improves resistance to physical stress, reduces signal interference, and minimizes attenuation in optical communications. The twisting process also aids in maintaining flexibility and durability, making twisted fiber ideal for applications requiring robust performance in dynamic environments.

Understanding Untwisted Fiber: Structure and Features

Untwisted fiber consists of individual filaments aligned parallel without any helical twisting, resulting in a smoother surface and consistent diameter throughout its length. This structure enhances light transmission efficiency by minimizing internal reflection and signal loss, making it ideal for high-precision fiber optic applications. The absence of twisting reduces mechanical stress on the fiber, improving flexibility and durability during installation and operation.

Key Differences Between Twisted and Untwisted Fibers

Twisted fiber cables consist of multiple strands twisted together to reduce electromagnetic interference and crosstalk, improving signal integrity and durability. Untwisted fiber cables lack this twisting, making them more susceptible to noise and signal degradation over longer distances. The twisting in fiber optics enhances performance in high-speed data transmission environments compared to untwisted fiber types.

Mechanical Properties Comparison: Strength, Flexibility, and Durability

Twisted fiber exhibits enhanced mechanical strength due to the interlocking structure of its strands, which distributes stress more evenly compared to untwisted fiber. Untwisted fiber offers greater flexibility, making it suitable for applications requiring bending and manipulation without breaking. Durability favors twisted fiber as its configuration resists wear and environmental damage better, resulting in longer service life.

Manufacturing Processes: Twisted vs Untwisted Fiber Production

Twisted fiber production involves spinning or twisting individual fibers together to enhance strength, flexibility, and durability, commonly used in textile manufacturing and composite materials. Untwisted fiber production focuses on aligning fibers in parallel without twisting, preserving fiber length and maximizing tensile properties, often favored in performance applications like filtration or reinforcements. Manufacturing processes vary in machinery and techniques, where twisting incorporates tension and rotation, while untwisted fiber techniques emphasize precise fiber arrangement and bonding.

Applications of Twisted Fiber in Industry

Twisted fiber is extensively used in telecommunications and data transmission industries due to its enhanced signal integrity and reduced electromagnetic interference. Its applications include networking cables, high-speed internet infrastructure, and fiber optic sensors in industrial automation. The twisting of fibers improves durability and performance, making twisted fiber ideal for harsh environmental conditions and critical industrial processes.

Applications of Untwisted Fiber in Industry

Untwisted fiber is widely utilized in industries requiring flexibility and high tensile strength, such as the textile and composite manufacturing sectors. Its structure allows for superior elongation and pliability, making it ideal for applications like weaving fabrics, producing ropes, and reinforcing materials in automotive and aerospace composites. Untwisted fibers also play a critical role in filtration systems and insulation products due to their open arrangement and increased surface area.

Performance and Suitability: Choosing the Right Fiber Type

Twisted fiber cables exhibit enhanced performance through reduced electromagnetic interference, making them ideal for high-speed data transmission in environments with significant signal noise. Untwisted fiber cables, while simpler and more cost-effective, are better suited for short-distance applications where interference is minimal and installation cost is a primary concern. Evaluating performance needs and environmental conditions is critical when selecting between twisted and untwisted fiber to ensure optimal network reliability and efficiency.

Future Trends and Innovations in Fiber Technology

Twisted fiber technology enhances signal integrity and reduces electromagnetic interference, making it a key focus in the development of next-generation high-speed communication networks. Emerging innovations include advanced twisting techniques combined with nano-coatings to increase bandwidth and durability while minimizing signal loss. Untwisted fiber, primarily used in simpler or legacy systems, is gradually being replaced as future trends prioritize the superior performance and scalability provided by twisted fiber optics.

Twisted Fiber vs Untwisted Fiber Infographic

materialdif.com

materialdif.com