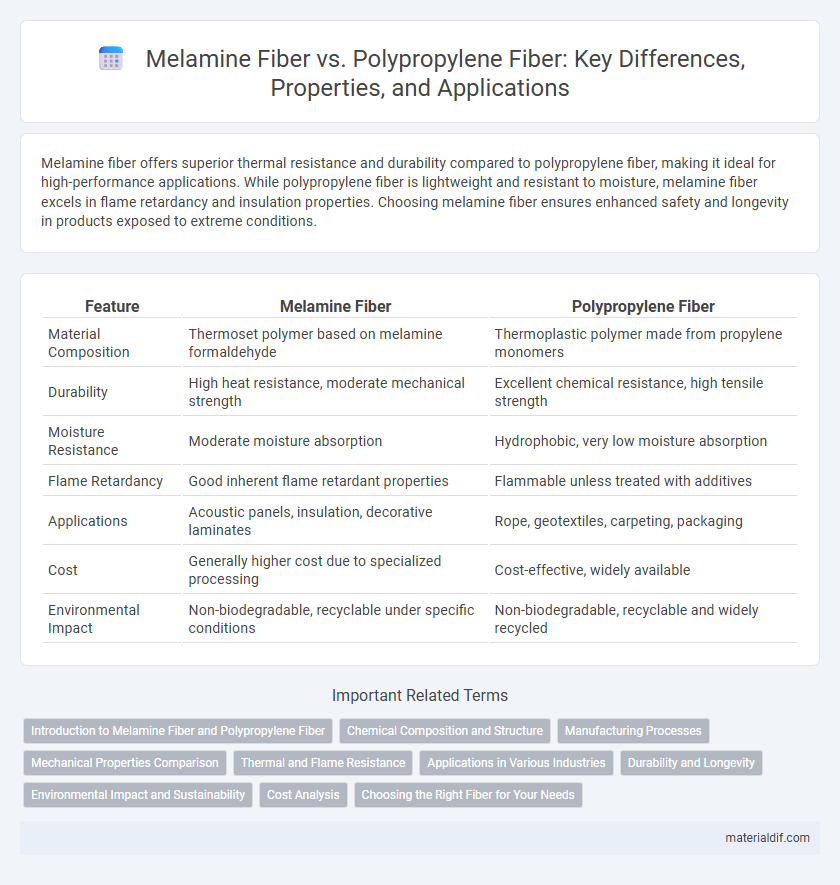

Melamine fiber offers superior thermal resistance and durability compared to polypropylene fiber, making it ideal for high-performance applications. While polypropylene fiber is lightweight and resistant to moisture, melamine fiber excels in flame retardancy and insulation properties. Choosing melamine fiber ensures enhanced safety and longevity in products exposed to extreme conditions.

Table of Comparison

| Feature | Melamine Fiber | Polypropylene Fiber |

|---|---|---|

| Material Composition | Thermoset polymer based on melamine formaldehyde | Thermoplastic polymer made from propylene monomers |

| Durability | High heat resistance, moderate mechanical strength | Excellent chemical resistance, high tensile strength |

| Moisture Resistance | Moderate moisture absorption | Hydrophobic, very low moisture absorption |

| Flame Retardancy | Good inherent flame retardant properties | Flammable unless treated with additives |

| Applications | Acoustic panels, insulation, decorative laminates | Rope, geotextiles, carpeting, packaging |

| Cost | Generally higher cost due to specialized processing | Cost-effective, widely available |

| Environmental Impact | Non-biodegradable, recyclable under specific conditions | Non-biodegradable, recyclable and widely recycled |

Introduction to Melamine Fiber and Polypropylene Fiber

Melamine fiber is a synthetic fiber known for its exceptional flame resistance, thermal stability, and durability, commonly used in upholstery, automotive interiors, and protective clothing. Polypropylene fiber is a lightweight, moisture-resistant synthetic fiber with excellent chemical resistance and high tensile strength, often utilized in geotextiles, filtration, and upholstery applications. Both fibers offer unique properties tailored to specific industrial uses, with melamine focusing on flame retardancy and polypropylene emphasizing moisture resistance and strength.

Chemical Composition and Structure

Melamine fiber is composed primarily of melamine-formaldehyde resin, featuring a rigid, cross-linked polymer structure that provides excellent thermal stability and flame resistance. Polypropylene fiber consists of long hydrocarbon chains of propylene monomers with a semi-crystalline structure, resulting in hydrophobic properties and high chemical resistance. The chemical composition of melamine fibers enables enhanced fire retardancy, while polypropylene fibers excel in chemical inertness and moisture resistance due to their non-polar molecular framework.

Manufacturing Processes

Melamine fiber is manufactured through a dry-spinning process, involving the polymerization of melamine-formaldehyde resin to create a durable and flame-retardant fiber with excellent thermal stability. Polypropylene fiber is produced using melt spinning, where polypropylene granules are melted and extruded into fine filaments, resulting in a lightweight, moisture-resistant fiber with high chemical resistance. These distinct manufacturing techniques influence the fibers' properties, making melamine fiber ideal for fireproof textiles and polypropylene fiber suitable for industrial and packaging applications.

Mechanical Properties Comparison

Melamine fiber exhibits superior tensile strength and higher modulus of elasticity compared to polypropylene fiber, making it ideal for applications requiring enhanced durability and stiffness. Polypropylene fiber, while possessing lower tensile strength, offers excellent impact resistance and flexibility, which benefits dynamic load conditions. Both fibers demonstrate distinct mechanical properties that influence their suitability for reinforcement in composite materials and textile manufacturing.

Thermal and Flame Resistance

Melamine fiber exhibits superior thermal stability with a decomposition temperature around 300degC, making it highly resistant to heat and flame, while polypropylene fiber melts at approximately 160degC and has limited flame retardancy. Melamine fibers are inherently flame retardant, self-extinguishing without the need for chemical treatments, whereas polypropylene requires additives to enhance fire resistance. This makes melamine fiber a preferred choice for applications demanding high thermal performance and stringent flame resistance standards.

Applications in Various Industries

Melamine fiber excels in high-temperature resistance and flame retardancy, making it ideal for automotive upholstery, industrial filters, and protective clothing in hazardous environments. Polypropylene fiber is widely used in packaging, geotextiles, and disposable hygiene products due to its lightweight, chemical resistance, and moisture-wicking properties. Both fibers contribute to the construction industry with melamine offering sound insulation panels and polypropylene reinforcing concrete structures.

Durability and Longevity

Melamine fiber exhibits exceptional durability due to its inherent flame resistance and chemical stability, making it ideal for high-performance textiles and insulation applications. Polypropylene fiber offers superior resistance to moisture, abrasion, and UV exposure, contributing to its long lifespan in outdoor and industrial environments. Both fibers provide excellent longevity, but melamine excels in thermal durability while polypropylene is preferred for mechanical wear and environmental resilience.

Environmental Impact and Sustainability

Melamine fiber demonstrates higher environmental sustainability due to its biodegradability and lower carbon footprint during production compared to polypropylene fiber, which is derived from non-renewable petroleum resources and contributes to microplastic pollution. Melamine fiber's eco-friendly lifecycle supports reduced waste accumulation and improved soil health, while polypropylene fiber persistence in the environment results in long-term ecological harm. Companies prioritizing sustainable textiles are increasingly favoring melamine fiber to align with global environmental standards and circular economy goals.

Cost Analysis

Melamine fiber typically incurs higher production costs due to its complex chemical processing and specialized applications, resulting in a premium market price compared to polypropylene fiber. Polypropylene fiber benefits from lower raw material costs and simplified manufacturing processes, making it a more cost-effective choice for large-scale industrial uses. Cost analysis reveals polypropylene fiber offers greater economic advantages in applications requiring bulk production and budget constraints, while melamine fiber's cost is justified by its superior heat resistance and flame-retardant properties.

Choosing the Right Fiber for Your Needs

Melamine fiber offers superior flame resistance, thermal stability, and moisture-wicking properties, making it ideal for applications requiring heat protection and durability. Polypropylene fiber excels in chemical resistance, low density, and cost-effectiveness, suitable for lightweight, moisture-prone environments such as geotextiles and packaging. Selecting between melamine and polypropylene fibers depends on specific performance requirements, environmental conditions, and budget constraints to ensure optimal functionality.

Melamine Fiber vs Polypropylene Fiber Infographic

materialdif.com

materialdif.com