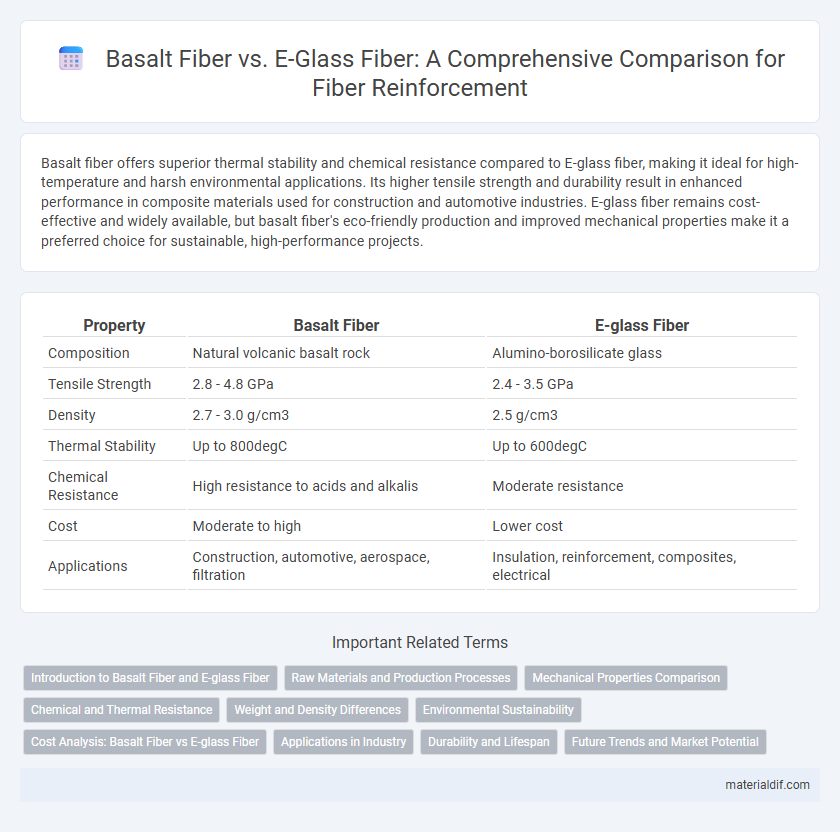

Basalt fiber offers superior thermal stability and chemical resistance compared to E-glass fiber, making it ideal for high-temperature and harsh environmental applications. Its higher tensile strength and durability result in enhanced performance in composite materials used for construction and automotive industries. E-glass fiber remains cost-effective and widely available, but basalt fiber's eco-friendly production and improved mechanical properties make it a preferred choice for sustainable, high-performance projects.

Table of Comparison

| Property | Basalt Fiber | E-glass Fiber |

|---|---|---|

| Composition | Natural volcanic basalt rock | Alumino-borosilicate glass |

| Tensile Strength | 2.8 - 4.8 GPa | 2.4 - 3.5 GPa |

| Density | 2.7 - 3.0 g/cm3 | 2.5 g/cm3 |

| Thermal Stability | Up to 800degC | Up to 600degC |

| Chemical Resistance | High resistance to acids and alkalis | Moderate resistance |

| Cost | Moderate to high | Lower cost |

| Applications | Construction, automotive, aerospace, filtration | Insulation, reinforcement, composites, electrical |

Introduction to Basalt Fiber and E-glass Fiber

Basalt fiber, made from natural volcanic rock, offers superior thermal stability and chemical resistance compared to E-glass fiber, which is composed of silica-based glass fibers commonly used in composites. E-glass fiber is valued for its high tensile strength and cost-effectiveness, making it widely used in automotive, construction, and aerospace industries. Both fibers serve crucial roles in reinforcing materials, with basalt fiber gaining popularity due to its eco-friendly production and enhanced durability.

Raw Materials and Production Processes

Basalt fiber is produced from natural volcanic basalt rock, which is melted at high temperatures and extruded into fibers, offering excellent thermal resistance and chemical stability. E-glass fiber, derived from a mixture of silica sand, limestone, and other minerals, undergoes a melting and fiberizing process tailored for electrical insulation and mechanical strength. The raw material purity and melting temperatures significantly influence the mechanical properties and durability of both basalt and E-glass fibers.

Mechanical Properties Comparison

Basalt fiber exhibits higher tensile strength ranging from 2,800 to 4,800 MPa compared to E-glass fiber's tensile strength of approximately 2,000 to 3,500 MPa, making it more suitable for high-performance applications. Basalt fiber also offers improved impact resistance and better thermal stability up to 700degC, whereas E-glass fiber typically degrades above 600degC. The superior mechanical properties of basalt fiber, including higher modulus of elasticity and enhanced durability, contribute to its growing preference in construction and automotive industries over traditional E-glass fiber.

Chemical and Thermal Resistance

Basalt fiber exhibits superior chemical resistance compared to E-glass fiber, with enhanced durability against acids, alkalis, and corrosive environments. Its thermal resistance also surpasses E-glass, maintaining structural integrity at temperatures up to 700degC, whereas E-glass typically withstands temperatures around 540degC. These properties make basalt fiber the preferred choice in high-performance applications requiring robust chemical and thermal stability.

Weight and Density Differences

Basalt fiber exhibits a density of approximately 2.7 to 2.8 g/cm3, which is slightly higher than E-glass fiber, typically around 2.54 g/cm3, resulting in marginally increased weight for basalt fiber composites. Despite its higher density, basalt fiber offers superior mechanical strength and better chemical resistance compared to E-glass, making it a durable choice for applications where weight is balanced against performance. Engineers consider these weight and density differences crucial when selecting fibers for lightweight structures in automotive and aerospace industries.

Environmental Sustainability

Basalt fiber offers superior environmental sustainability compared to E-glass fiber due to its natural volcanic rock raw material, which requires less energy-intensive processing and generates lower carbon emissions. Basalt fibers are fully recyclable and non-toxic, reducing environmental impact during production and disposal. In contrast, E-glass fiber relies on silica sand and other raw materials that demand higher energy consumption and produce more harmful waste products.

Cost Analysis: Basalt Fiber vs E-glass Fiber

Basalt fiber generally offers a competitive cost advantage over E-glass fiber due to lower raw material expenses and environmentally friendly processing methods. While E-glass fiber is widely available and benefits from established manufacturing infrastructure, its production involves higher energy consumption, influencing overall costs. Basalt fiber's enhanced durability and thermal resistance can reduce lifecycle expenses, making it a cost-effective choice in applications requiring long-term performance.

Applications in Industry

Basalt fiber offers superior thermal stability and chemical resistance compared to E-glass fiber, making it ideal for heavy-duty industrial applications such as automotive components, construction materials, and fire-proof insulation. E-glass fiber remains the preferred choice in industries requiring cost-effective solutions with moderate strength, including marine, aerospace, and electrical insulation applications. The selection between basalt and E-glass fiber depends heavily on the specific performance requirements and environmental conditions of the industrial use case.

Durability and Lifespan

Basalt fiber exhibits superior durability compared to E-glass fiber due to its excellent resistance to chemical corrosion, UV radiation, and high temperatures, ensuring prolonged structural integrity in harsh environments. The lifespan of basalt fiber can exceed 30 years, outperforming E-glass fiber, which typically lasts around 20 to 25 years under similar conditions. Enhanced mechanical strength and weather resistance make basalt fiber a preferred choice for applications demanding long-term durability and reliability.

Future Trends and Market Potential

Basalt fiber exhibits superior thermal stability and eco-friendliness compared to E-glass fiber, positioning it as a promising material for advanced composites in aerospace and automotive industries. Market projections indicate a robust CAGR of over 10% for basalt fiber due to increasing demand for sustainable and high-performance materials. Innovations in production technologies and rising awareness of environmental impacts are expected to drive basalt fiber adoption, potentially challenging the dominant E-glass fiber market share in the next decade.

Basalt Fiber vs E-glass Fiber Infographic

materialdif.com

materialdif.com