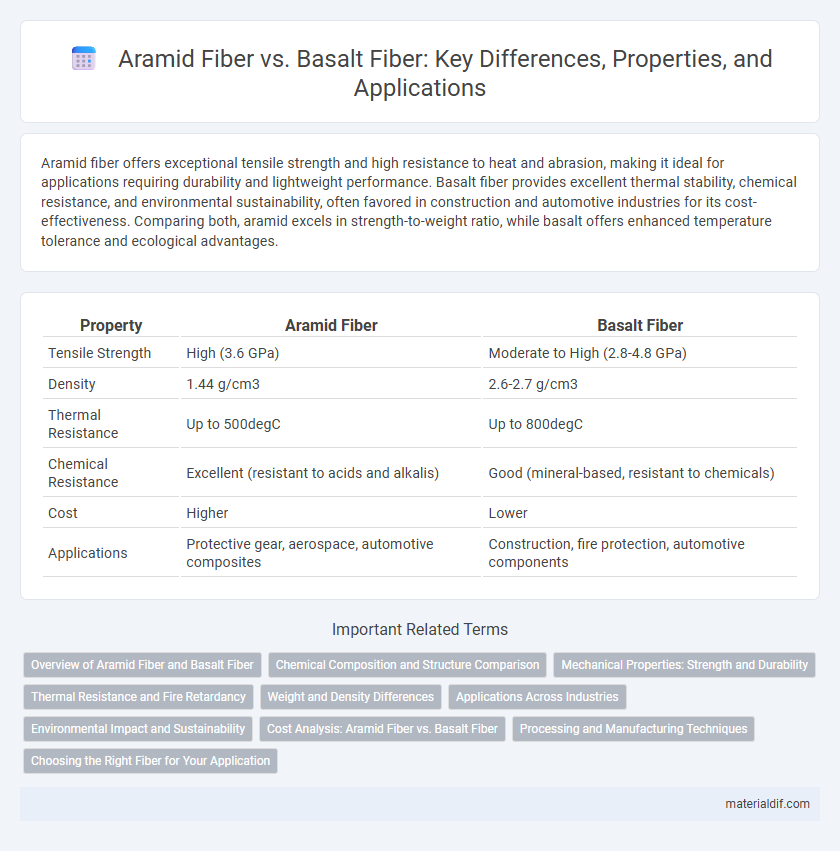

Aramid fiber offers exceptional tensile strength and high resistance to heat and abrasion, making it ideal for applications requiring durability and lightweight performance. Basalt fiber provides excellent thermal stability, chemical resistance, and environmental sustainability, often favored in construction and automotive industries for its cost-effectiveness. Comparing both, aramid excels in strength-to-weight ratio, while basalt offers enhanced temperature tolerance and ecological advantages.

Table of Comparison

| Property | Aramid Fiber | Basalt Fiber |

|---|---|---|

| Tensile Strength | High (3.6 GPa) | Moderate to High (2.8-4.8 GPa) |

| Density | 1.44 g/cm3 | 2.6-2.7 g/cm3 |

| Thermal Resistance | Up to 500degC | Up to 800degC |

| Chemical Resistance | Excellent (resistant to acids and alkalis) | Good (mineral-based, resistant to chemicals) |

| Cost | Higher | Lower |

| Applications | Protective gear, aerospace, automotive composites | Construction, fire protection, automotive components |

Overview of Aramid Fiber and Basalt Fiber

Aramid fiber, renowned for its exceptional strength-to-weight ratio and high heat resistance, is widely used in aerospace, military, and automotive applications where durability and thermal stability are critical. Basalt fiber, derived from natural volcanic rock, offers excellent mechanical properties, chemical resistance, and is environmentally friendly, making it ideal for construction, insulation, and composite materials. Both fibers exhibit unique advantages: aramid excels in tensile strength and impact resistance, while basalt provides superior corrosion resistance and sustainability.

Chemical Composition and Structure Comparison

Aramid fiber consists primarily of poly-paraphenylene terephthalamide, characterized by rigid aromatic polyamide chains that provide high tensile strength and thermal stability. Basalt fiber is composed mainly of natural volcanic basalt rock, containing silica, alumina, and iron oxides, resulting in a glass-like, amorphous structure with excellent chemical and corrosion resistance. The crystalline structure of aramid fibers contrasts with the amorphous, inorganic composition of basalt fibers, influencing their respective mechanical properties and durability in harsh environments.

Mechanical Properties: Strength and Durability

Aramid fiber exhibits exceptional tensile strength ranging from 2,400 to 3,500 MPa, making it highly resistant to impact and abrasion, which contributes to superior durability in demanding applications. Basalt fiber offers impressive mechanical properties as well, with tensile strength typically between 1,000 and 1,800 MPa, providing excellent resistance to chemical corrosion and thermal stability up to 1,000degC. While aramid fiber excels in high strength-to-weight ratio and flexibility, basalt fiber stands out for enhanced durability under high-temperature and harsh environmental conditions.

Thermal Resistance and Fire Retardancy

Aramid fiber exhibits exceptional thermal resistance with a decomposition temperature above 500degC, making it highly effective for fire retardancy applications. Basalt fiber offers superior thermal stability, withstanding temperatures up to 800degC without significant degradation, providing enhanced fire resistance in extreme conditions. Both fibers serve critical roles in fire-resistant materials, but basalt fiber excels in higher temperature endurance, while aramid fiber provides superior structural integrity under thermal stress.

Weight and Density Differences

Aramid fiber exhibits a lower density, typically around 1.44 g/cm3, compared to basalt fiber, which ranges from 2.7 to 3.0 g/cm3, making aramid significantly lighter. This weight advantage makes aramid fiber ideal for applications requiring high strength-to-weight ratios, such as aerospace and automotive sectors. Despite basalt fiber's higher density, its superior thermal stability and cost-effectiveness offer alternative benefits where weight is less critical.

Applications Across Industries

Aramid fiber is widely used in aerospace, automotive, and military applications due to its exceptional tensile strength and impact resistance, making it ideal for protective gear, body armor, and high-performance composites. Basalt fiber finds extensive use in construction, infrastructure, and marine industries because of its excellent thermal stability, corrosion resistance, and cost-effectiveness, supporting applications such as rebar replacement, insulation, and fireproof textiles. Both fibers contribute significantly to lightweight and durable material solutions, with aramid excelling in high-stress environments and basalt providing sustainable alternatives in harsh environmental conditions.

Environmental Impact and Sustainability

Aramid fiber and basalt fiber differ significantly in environmental impact and sustainability; basalt fiber is derived from natural volcanic rock, making its production more eco-friendly with minimal chemical use and lower energy consumption compared to the petroleum-based synthesis of aramid fiber. Basalt fiber offers excellent biodegradability and recyclability, contributing to reduced environmental footprint over its lifecycle. Aramid fiber, while high-performance and durable, involves complex chemical processes that generate more hazardous waste and fossil fuel dependency, impacting long-term sustainability.

Cost Analysis: Aramid Fiber vs. Basalt Fiber

Aramid fiber typically incurs higher costs due to complex manufacturing processes and premium raw materials, whereas basalt fiber offers a more cost-effective alternative with abundant natural resource availability. Basalt fiber's lower production expenses result in competitive pricing, making it a favorable option for large-scale industrial applications requiring budget efficiency. Despite price differences, the cost-performance balance depends on specific application requirements and long-term durability considerations of each fiber type.

Processing and Manufacturing Techniques

Aramid fiber manufacturing involves complex wet spinning processes that require solvent recovery systems and high-temperature curing to achieve its high strength and heat resistance. Basalt fiber production uses a simpler melt extrusion technique by melting basalt rock at around 1450degC, followed by rapid cooling and fiber drawing, which reduces energy consumption and environmental impact. The ease of processing basalt fiber allows for scalable production with lower costs compared to the more chemically intensive and sensitive processing required for aramid fibers.

Choosing the Right Fiber for Your Application

Aramid fiber offers exceptional tensile strength and impact resistance, making it ideal for ballistic protection and aerospace applications requiring lightweight durability. Basalt fiber excels in chemical resistance and thermal stability, suited for construction and automotive industries exposed to harsh environmental conditions. Selecting the right fiber depends on specific application requirements, such as strength-to-weight ratio, temperature tolerance, and exposure to chemicals or UV radiation.

Aramid fiber vs Basalt fiber Infographic

materialdif.com

materialdif.com