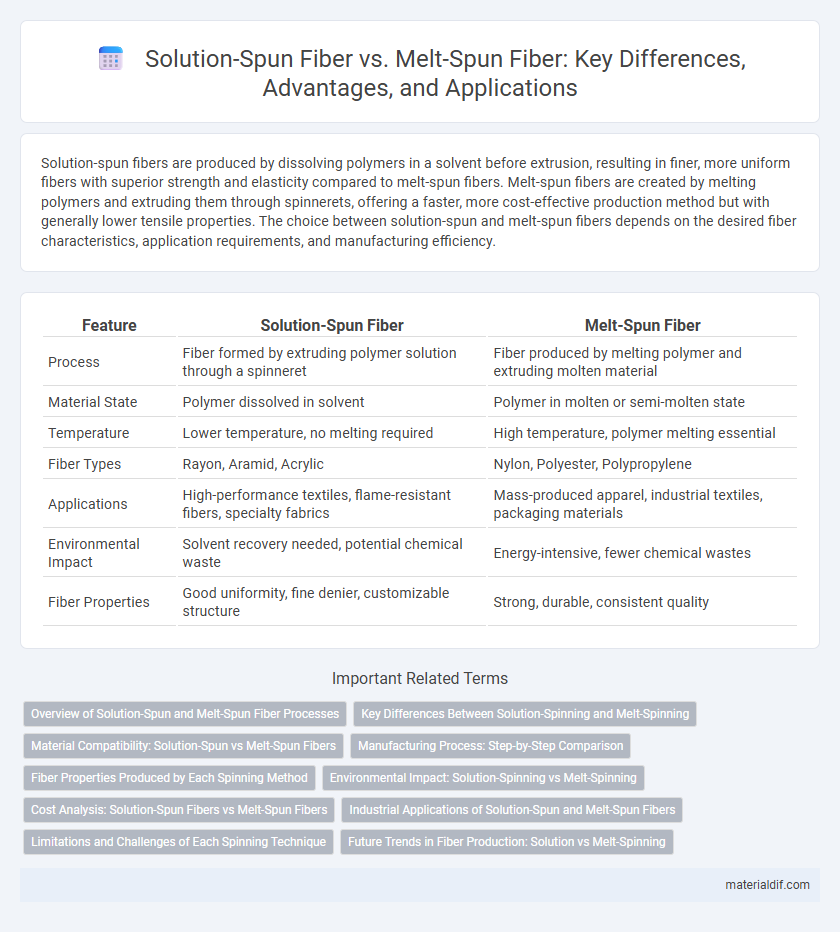

Solution-spun fibers are produced by dissolving polymers in a solvent before extrusion, resulting in finer, more uniform fibers with superior strength and elasticity compared to melt-spun fibers. Melt-spun fibers are created by melting polymers and extruding them through spinnerets, offering a faster, more cost-effective production method but with generally lower tensile properties. The choice between solution-spun and melt-spun fibers depends on the desired fiber characteristics, application requirements, and manufacturing efficiency.

Table of Comparison

| Feature | Solution-Spun Fiber | Melt-Spun Fiber |

|---|---|---|

| Process | Fiber formed by extruding polymer solution through a spinneret | Fiber produced by melting polymer and extruding molten material |

| Material State | Polymer dissolved in solvent | Polymer in molten or semi-molten state |

| Temperature | Lower temperature, no melting required | High temperature, polymer melting essential |

| Fiber Types | Rayon, Aramid, Acrylic | Nylon, Polyester, Polypropylene |

| Applications | High-performance textiles, flame-resistant fibers, specialty fabrics | Mass-produced apparel, industrial textiles, packaging materials |

| Environmental Impact | Solvent recovery needed, potential chemical waste | Energy-intensive, fewer chemical wastes |

| Fiber Properties | Good uniformity, fine denier, customizable structure | Strong, durable, consistent quality |

Overview of Solution-Spun and Melt-Spun Fiber Processes

Solution-spun fibers are produced by dissolving polymers in a solvent to create a viscous solution, which is then extruded through spinnerets and solidified by coagulation or evaporation. Melt-spun fibers involve melting polymers into a liquid state before extrusion through spinnerets, followed by rapid cooling to solidify the fibers. The primary difference lies in the processing conditions, with solution spinning suitable for polymers that degrade at high temperatures, while melt spinning is faster and more cost-effective for thermoplastic polymers.

Key Differences Between Solution-Spinning and Melt-Spinning

Solution-spun fiber involves dissolving polymers in a solvent before extrusion, allowing precise control over fiber morphology and enabling the production of fibers from temperature-sensitive polymers. Melt-spun fiber requires melting the polymer pellets and extruding them through spinnerets, offering faster production with fewer chemical hazards but limited to thermoplastic materials with suitable melting points. Key differences include the use of solvents in solution spinning versus heat in melt spinning, impacting fiber properties, production speed, and environmental considerations.

Material Compatibility: Solution-Spun vs Melt-Spun Fibers

Solution-spun fibers exhibit superior material compatibility with sensitive polymers, enabling the incorporation of heat-sensitive additives and biopolymers that degrade at high temperatures. Melt-spun fibers require polymers with high thermal stability due to the elevated melting and extrusion temperatures involved in the process. The ability of solution-spinning to process a broader range of polymers enhances its application versatility in advanced textile and composite materials.

Manufacturing Process: Step-by-Step Comparison

Solution-spun fiber manufacturing involves dissolving polymers in a solvent to create a viscous solution that is extruded through spinnerets into a coagulation bath, where fibers solidify via solvent exchange. Melt-spun fiber production melts polymer pellets and forces the molten polymer through spinnerets into cool air or water, solidifying fibers by cooling instead of solvent removal. Solution spinning requires solvent recovery systems and precise chemical handling, while melt spinning emphasizes temperature control and polymer viscosity to ensure fiber uniformity.

Fiber Properties Produced by Each Spinning Method

Solution-spun fibers exhibit superior tensile strength and flexibility due to the controlled molecular orientation during the spinning process, making them ideal for high-performance applications. Melt-spun fibers typically show enhanced thermal stability and faster production rates, but they may have lower uniformity in fiber diameter compared to solution-spun fibers. The choice between solution-spun and melt-spun fibers directly impacts properties like tensile modulus, elongation at break, and surface smoothness, influencing end-use performance in textiles and composites.

Environmental Impact: Solution-Spinning vs Melt-Spinning

Solution-spun fibers typically generate less pollution since the solvents used in the process can often be recycled, reducing overall waste and environmental footprint. Melt-spun fibers bypass solvent use entirely, minimizing chemical emissions but consuming higher energy due to the melting process. Evaluating the environmental impact depends on solvent recovery efficiency in solution spinning and energy sources powering melt spinning operations.

Cost Analysis: Solution-Spun Fibers vs Melt-Spun Fibers

Solution-spun fibers generally incur higher production costs due to the use of specialized solvents and additional purification steps compared to melt-spun fibers, which leverage direct melting of polymers with lower energy consumption. Melt-spun fibers benefit from faster processing times and reduced equipment expenses, making them more cost-effective for large-scale manufacturing. However, solution-spun fibers provide superior material properties that may justify their elevated cost in high-performance applications.

Industrial Applications of Solution-Spun and Melt-Spun Fibers

Solution-spun fibers, such as rayon and aramid fibers, are extensively used in the automotive and aerospace industries for their high tensile strength and heat resistance. Melt-spun fibers, including polypropylene and nylon, dominate textile manufacturing and packaging due to their efficient production process and versatility. Both fiber types contribute to industrial applications by offering tailored mechanical properties and cost-effective fabrication techniques.

Limitations and Challenges of Each Spinning Technique

Solution-spun fiber faces limitations such as solvent recovery difficulties and environmental concerns due to the use of toxic chemicals, impacting production costs and sustainability. Melt-spun fiber encounters challenges like high energy consumption from melting polymers and limited suitability for heat-sensitive materials, restricting its application range. Both techniques require advanced control over processing parameters to ensure consistent fiber quality and performance.

Future Trends in Fiber Production: Solution vs Melt-Spinning

Solution-spun fibers are expected to gain traction due to their superior control over fiber morphology and ability to incorporate functional additives, enhancing performance in technical textiles and smart fabrics. Melt-spinning remains dominant for large-scale, cost-effective production, especially with advancements in polymer recycling and bio-based materials that improve sustainability. Future fiber production trends will likely blend the precision of solution spinning with the scalability of melt spinning, driven by growing demands for high-performance, eco-friendly fibers.

Solution-Spun Fiber vs Melt-Spun Fiber Infographic

materialdif.com

materialdif.com