Lyocell fiber offers superior moisture absorption and breathability compared to modal fiber, making it ideal for activewear and sensitive skin. Modal fiber, derived from beech trees, is known for its exceptional softness and smooth texture, enhancing comfort in loungewear and bedding. Both fibers are eco-friendly, but lyocell's closed-loop production process reduces environmental impact more significantly than modal manufacturing.

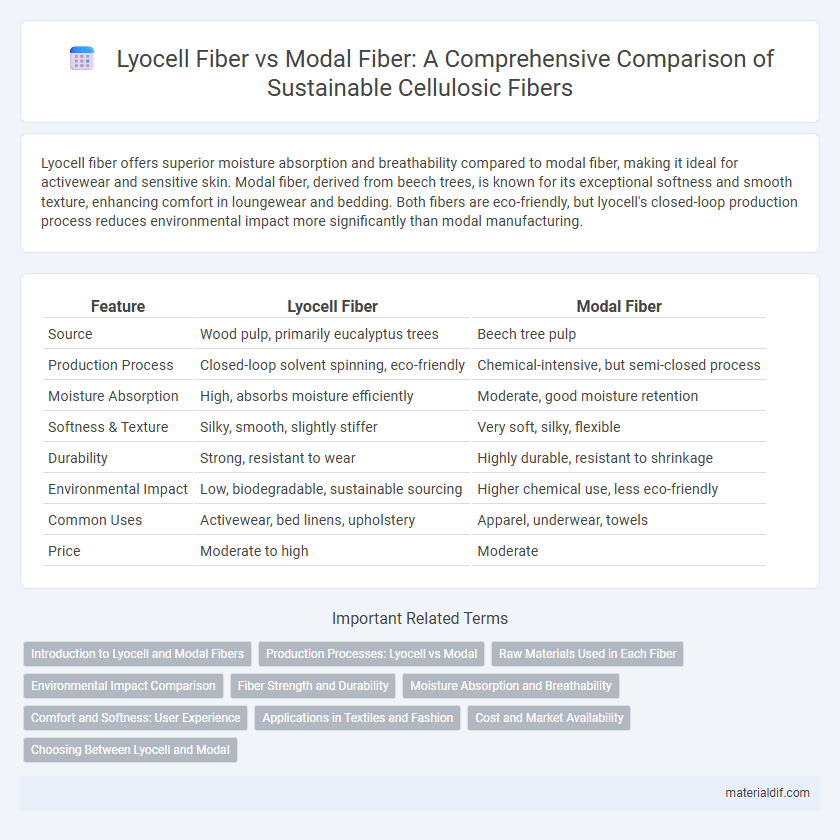

Table of Comparison

| Feature | Lyocell Fiber | Modal Fiber |

|---|---|---|

| Source | Wood pulp, primarily eucalyptus trees | Beech tree pulp |

| Production Process | Closed-loop solvent spinning, eco-friendly | Chemical-intensive, but semi-closed process |

| Moisture Absorption | High, absorbs moisture efficiently | Moderate, good moisture retention |

| Softness & Texture | Silky, smooth, slightly stiffer | Very soft, silky, flexible |

| Durability | Strong, resistant to wear | Highly durable, resistant to shrinkage |

| Environmental Impact | Low, biodegradable, sustainable sourcing | Higher chemical use, less eco-friendly |

| Common Uses | Activewear, bed linens, upholstery | Apparel, underwear, towels |

| Price | Moderate to high | Moderate |

Introduction to Lyocell and Modal Fibers

Lyocell fiber is a sustainable regenerated cellulose fiber made from wood pulp, known for its softness, strength, and moisture-wicking properties. Modal fiber, also derived from beech tree pulp, offers a smooth texture with excellent breathability and greater dye affinity, enhancing color vibrancy. Both fibers belong to the rayon family but differ in production processes and environmental impact, making them popular choices in eco-friendly textile manufacturing.

Production Processes: Lyocell vs Modal

Lyocell fiber is produced using a closed-loop solvent spinning process that dissolves wood pulp in N-methylmorpholine N-oxide, ensuring high environmental sustainability and minimal chemical waste. Modal fiber undergoes a chemical-intensive process involving the regeneration of cellulose from beech wood pulp using alkali and carbon disulfide in a viscose method, which results in higher chemical use and environmental impact. The eco-friendliness of Lyocell's production distinguishes it significantly from Modal, with Lyocell offering superior fiber purity and sustainability credentials.

Raw Materials Used in Each Fiber

Lyocell fiber is derived from sustainably sourced wood pulp, primarily from eucalyptus, beech, and spruce trees, using a closed-loop production process that minimizes environmental impact. Modal fiber is made from reconstituted cellulose, mainly sourced from beech tree wood, employing a chemical-intensive process to regenerate the cellulose into fibers. Both fibers originate from natural cellulose, but Lyocell's production emphasizes eco-friendly raw material sourcing and solvent recovery compared to Modal's conventional chemical extraction methods.

Environmental Impact Comparison

Lyocell fiber is produced using a closed-loop process that recycles water and solvents, significantly reducing environmental pollution compared to modal fiber production, which often relies on chemical-intensive methods. Lyocell's raw material, sustainably sourced wood pulp, contributes to lower carbon emissions and reduced deforestation risks, whereas modal fiber typically originates from beech trees with less emphasis on sustainability certifications. The biodegradability and lower energy consumption of lyocell further enhance its environmental profile relative to modal fiber, making it a preferable choice for eco-conscious textile manufacturing.

Fiber Strength and Durability

Lyocell fiber offers superior strength and durability compared to modal fiber, thanks to its closed-loop production process that preserves the integrity of the cellulose. This results in higher tensile strength and better resistance to wear, making lyocell ideal for garments requiring long-lasting performance. Modal fiber, while soft and flexible, tends to have lower fiber strength and may show signs of pilling and weakening after repeated washes.

Moisture Absorption and Breathability

Lyocell fiber exhibits superior moisture absorption compared to modal fiber, absorbing up to 50% more water due to its unique cellulose structure derived from sustainably sourced wood pulp. Its enhanced breathability promotes better air circulation, making it ideal for activewear and moisture-wicking textiles. Modal fiber, while breathable, retains slightly less moisture and is often blended to improve softness and durability rather than high-performance moisture management.

Comfort and Softness: User Experience

Lyocell fiber offers superior moisture-wicking properties and breathability, providing enhanced comfort during extended wear compared to modal fiber. Modal fiber is renowned for its silky softness and smooth texture, delivering a luxurious tactile experience ideal for sensitive skin. Users often prefer lyocell for active lifestyles due to its durability and cooling effect, while modal is favored for loungewear thanks to its plush softness.

Applications in Textiles and Fashion

Lyocell fiber is widely used in sustainable fashion and high-performance activewear due to its exceptional moisture-wicking and breathable properties. Modal fiber excels in luxury textile applications such as underwear, loungewear, and bed linens because of its silky texture and excellent color retention. Both fibers enhance fabric softness and durability, making them popular choices for eco-friendly and comfortable apparel.

Cost and Market Availability

Lyocell fiber generally commands a higher price than modal fiber due to its more environmentally friendly closed-loop production process. Modal fiber benefits from broader market availability and is often found at lower price points, making it a popular choice in mass-market textile applications. The cost difference influences fiber selection in industries prioritizing sustainability versus budget-conscious manufacturing.

Choosing Between Lyocell and Modal

Lyocell fiber offers superior moisture-wicking and breathability compared to modal fiber, making it ideal for activewear and high-performance textiles. Modal fiber excels in softness and durability, providing a luxurious feel suitable for loungewear and bedding. Selecting between lyocell and modal depends on prioritizing either moisture management and sustainability or a smooth texture and long-lasting comfort.

Lyocell Fiber vs Modal Fiber Infographic

materialdif.com

materialdif.com