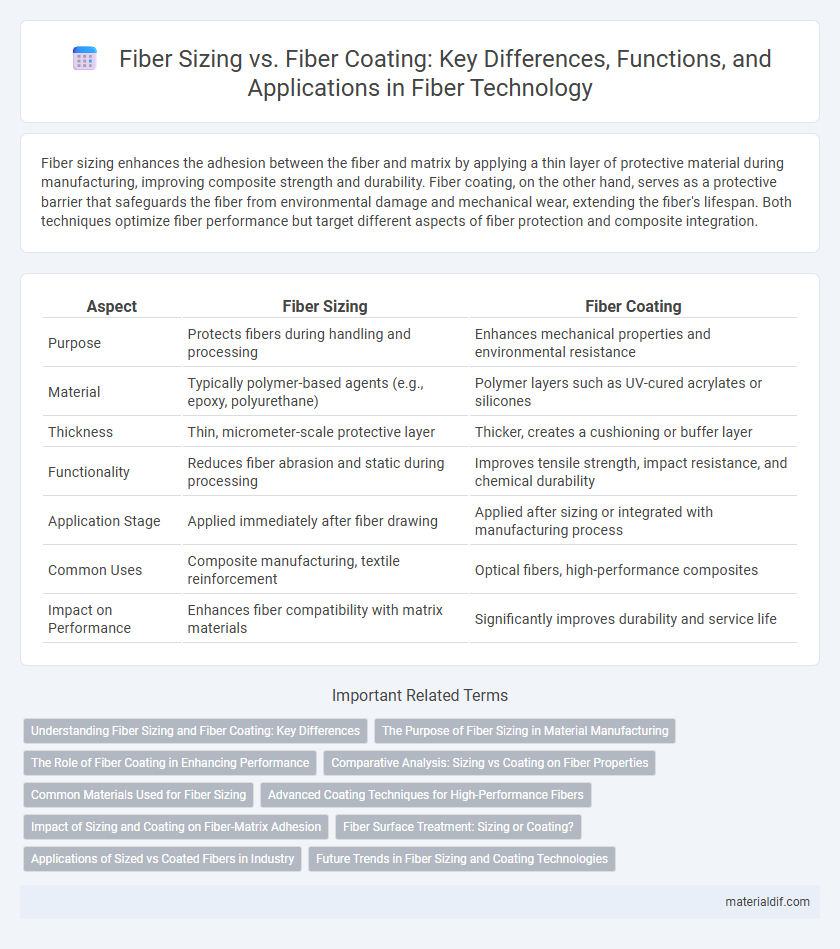

Fiber sizing enhances the adhesion between the fiber and matrix by applying a thin layer of protective material during manufacturing, improving composite strength and durability. Fiber coating, on the other hand, serves as a protective barrier that safeguards the fiber from environmental damage and mechanical wear, extending the fiber's lifespan. Both techniques optimize fiber performance but target different aspects of fiber protection and composite integration.

Table of Comparison

| Aspect | Fiber Sizing | Fiber Coating |

|---|---|---|

| Purpose | Protects fibers during handling and processing | Enhances mechanical properties and environmental resistance |

| Material | Typically polymer-based agents (e.g., epoxy, polyurethane) | Polymer layers such as UV-cured acrylates or silicones |

| Thickness | Thin, micrometer-scale protective layer | Thicker, creates a cushioning or buffer layer |

| Functionality | Reduces fiber abrasion and static during processing | Improves tensile strength, impact resistance, and chemical durability |

| Application Stage | Applied immediately after fiber drawing | Applied after sizing or integrated with manufacturing process |

| Common Uses | Composite manufacturing, textile reinforcement | Optical fibers, high-performance composites |

| Impact on Performance | Enhances fiber compatibility with matrix materials | Significantly improves durability and service life |

Understanding Fiber Sizing and Fiber Coating: Key Differences

Fiber sizing refers to the application of a protective chemical layer that enhances fiber compatibility with matrix materials and improves handling during processing, while fiber coating involves a thicker, often functional layer designed to provide additional mechanical protection and specific surface properties. Sizing primarily ensures adhesion and protects fibers from damage and contamination during composite manufacturing, whereas coatings tailor the fiber surface for enhanced performance in specialized environments or applications. Understanding these distinctions is crucial for optimizing composite material performance and durability in industries such as aerospace, automotive, and construction.

The Purpose of Fiber Sizing in Material Manufacturing

Fiber sizing plays a critical role in material manufacturing by enhancing the compatibility between fibers and matrix materials, improving adhesion and mechanical properties. It acts as a protective layer that prevents fiber damage during processing and ensures efficient load transfer within composites. Unlike fiber coating, which primarily provides a protective or functional surface finish, sizing optimizes interfacial bonding and processing efficiency in composite production.

The Role of Fiber Coating in Enhancing Performance

Fiber coating plays a crucial role in enhancing the mechanical and environmental performance of optical fibers by providing protection against abrasion, moisture, and microbending losses. Properly applied coatings improve the fiber's tensile strength and long-term durability, ensuring signal integrity in diverse operating conditions. Advanced polymer coatings also minimize attenuation and preserve the fiber's optical properties during installation and usage.

Comparative Analysis: Sizing vs Coating on Fiber Properties

Fiber sizing enhances mechanical protection and improves compatibility with resin matrices by applying a thin chemical layer, whereas fiber coating primarily serves to increase durability and resistance to environmental factors. Sizing affects fiber-matrix adhesion and processing performance, influencing tensile strength and interfacial bonding, while coatings typically improve abrasion resistance and extend fiber lifespan in harsh conditions. Comparative analysis reveals that sizing focuses on optimizing composite manufacturing and mechanical integration, whereas coatings prioritize protective functionalities and fiber longevity.

Common Materials Used for Fiber Sizing

Common materials used for fiber sizing include epoxy resins, polyurethane, and acrylics, which enhance fiber handling and compatibility with matrix resins. These sizing agents provide adhesion, protect fibers from damage, and improve composite mechanical properties. Selection of sizing materials depends on the fiber type, intended composite application, and the curing process of the matrix resin.

Advanced Coating Techniques for High-Performance Fibers

Advanced coating techniques for high-performance fibers enhance durability, flexibility, and environmental resistance by precisely controlling fiber sizing and surface chemistry. Fiber sizing involves applying a protective layer to reduce friction and prevent damage during processing, while advanced fiber coatings integrate nanomaterials or multifunctional polymers that improve mechanical strength and chemical stability. These innovations optimize fiber-matrix adhesion in composites, leading to superior performance in aerospace, automotive, and industrial applications.

Impact of Sizing and Coating on Fiber-Matrix Adhesion

Fiber sizing improves fiber-matrix adhesion by enhancing surface compatibility and protecting fibers during composite processing, leading to better stress transfer and overall composite strength. Fiber coating, often a distinct layer applied to the fiber, modifies the chemical and physical interaction at the fiber-matrix interface, promoting durable bonding and resistance to environmental degradation. Differences in fiber sizing and coating formulations directly affect the interfacial shear strength and long-term performance of composite materials in structural applications.

Fiber Surface Treatment: Sizing or Coating?

Fiber sizing is a surface treatment applied to reinforce fiber-matrix adhesion and protect fibers during handling by depositing a thin polymer layer compatible with composite resins. Fiber coating, on the other hand, serves primarily as a protective barrier to prevent abrasion and environmental damage without significantly altering interfacial bonding properties. Selecting between fiber sizing and fiber coating depends on the desired balance of mechanical performance, durability, and processing requirements in composite manufacturing.

Applications of Sized vs Coated Fibers in Industry

Sized fibers are primarily used in composite manufacturing, enhancing adhesion between fibers and matrix materials in aerospace, automotive, and sporting goods industries to improve mechanical properties. Coated fibers offer protection against environmental factors like moisture and abrasion, making them suitable for optical communications, medical devices, and electronics where durability and signal integrity are critical. The choice between sizing and coating depends on application requirements such as strength, flexibility, and environmental resistance, influencing performance in sectors like construction, telecommunications, and healthcare.

Future Trends in Fiber Sizing and Coating Technologies

Future trends in fiber sizing and coating technologies emphasize the development of bio-based and environmentally friendly materials to enhance sustainability in textile manufacturing. Advanced nanocoatings are being engineered to improve fiber durability, moisture management, and resistance to abrasion without compromising flexibility. Integration of smart coatings with sensing capabilities is expected to revolutionize fiber performance monitoring and adaptive textile applications.

Fiber Sizing vs Fiber Coating Infographic

materialdif.com

materialdif.com