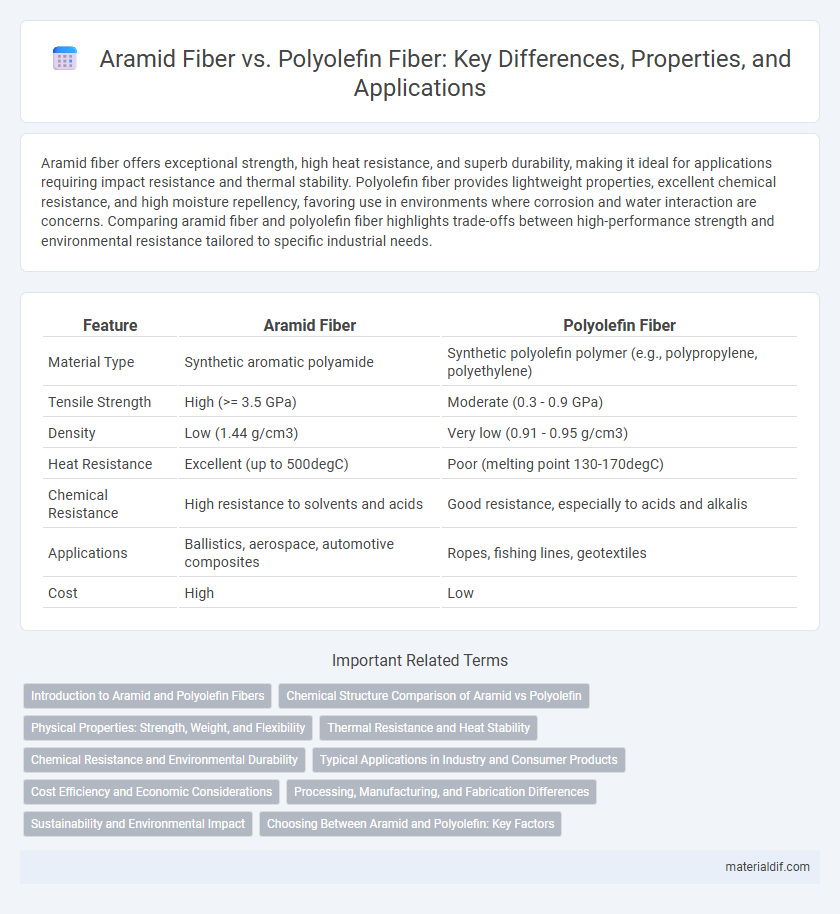

Aramid fiber offers exceptional strength, high heat resistance, and superb durability, making it ideal for applications requiring impact resistance and thermal stability. Polyolefin fiber provides lightweight properties, excellent chemical resistance, and high moisture repellency, favoring use in environments where corrosion and water interaction are concerns. Comparing aramid fiber and polyolefin fiber highlights trade-offs between high-performance strength and environmental resistance tailored to specific industrial needs.

Table of Comparison

| Feature | Aramid Fiber | Polyolefin Fiber |

|---|---|---|

| Material Type | Synthetic aromatic polyamide | Synthetic polyolefin polymer (e.g., polypropylene, polyethylene) |

| Tensile Strength | High (>= 3.5 GPa) | Moderate (0.3 - 0.9 GPa) |

| Density | Low (1.44 g/cm3) | Very low (0.91 - 0.95 g/cm3) |

| Heat Resistance | Excellent (up to 500degC) | Poor (melting point 130-170degC) |

| Chemical Resistance | High resistance to solvents and acids | Good resistance, especially to acids and alkalis |

| Applications | Ballistics, aerospace, automotive composites | Ropes, fishing lines, geotextiles |

| Cost | High | Low |

Introduction to Aramid and Polyolefin Fibers

Aramid fibers, known for their exceptional strength and heat resistance, are widely used in aerospace, military, and industrial applications due to their ability to maintain integrity under extreme conditions. Polyolefin fibers, including polyethylene and polypropylene variants, offer lightweight, chemical resistance, and high moisture-wicking properties, making them ideal for automotive, medical, and textile industries. Both fibers serve specialized roles, with aramid excelling in durability and polyolefin favored for cost-effective, versatile performance.

Chemical Structure Comparison of Aramid vs Polyolefin

Aramid fibers consist of aromatic polyamide chains with rigid, rod-like molecular structures, providing exceptional thermal stability and high strength-to-weight ratios. Polyolefin fibers, primarily made from long-chain hydrocarbon polymers like polyethylene or polypropylene, feature flexible, saturated carbon-carbon backbones resulting in lower melting points and reduced chemical resistance. The presence of amide linkages in aramids creates strong interchain hydrogen bonding absent in polyolefins, explaining aramid's superior mechanical and chemical performance.

Physical Properties: Strength, Weight, and Flexibility

Aramid fiber exhibits superior tensile strength and excellent heat resistance compared to polyolefin fiber, making it ideal for high-performance applications. Polyolefin fiber is lighter in weight and offers greater flexibility, which enhances its comfort and adaptability in wearable textiles. Both fibers provide distinct advantages depending on the balance required between strength, weight, and flexibility in specific industrial or consumer products.

Thermal Resistance and Heat Stability

Aramid fiber exhibits superior thermal resistance, maintaining structural integrity at temperatures up to 500degC, making it ideal for high-heat applications. Polyolefin fiber, while offering good chemical resistance, typically degrades around 150degC to 200degC, limiting its use in environments with extreme heat. The enhanced heat stability of aramid fibers stems from their aromatic polyamide molecular structure, providing durability in harsh thermal conditions compared to the aliphatic composition of polyolefin fibers.

Chemical Resistance and Environmental Durability

Aramid fiber exhibits superior chemical resistance, especially against solvents, alkalis, and acids, outperforming polyolefin fiber, which tends to degrade under strong chemical exposure. Polyolefin fibers, such as polypropylene and polyethylene, offer excellent environmental durability with high resistance to moisture, UV radiation, and oxidation, whereas aramid fibers can experience reduced strength and yellowing when exposed to prolonged UV light. Selecting between aramid and polyolefin fibers depends on the application's specific chemical exposure and environmental conditions to balance performance and longevity.

Typical Applications in Industry and Consumer Products

Aramid fiber, known for its exceptional strength, heat resistance, and durability, is widely used in aerospace, military protective gear, automotive reinforcement, and high-performance sporting goods. Polyolefin fiber, characterized by its lightweight, moisture resistance, and chemical stability, is commonly found in packaging materials, medical textiles, geo-textiles, and consumer apparel such as activewear and underwear. Both fibers serve distinct industrial and consumer applications based on their unique performance properties.

Cost Efficiency and Economic Considerations

Aramid fiber offers exceptional strength-to-weight ratio and superior heat resistance, making it ideal for high-performance applications, but it comes with a higher price tag compared to polyolefin fiber. Polyolefin fiber is significantly more cost-efficient, with lower raw material and production costs, providing economic advantages in large-volume and budget-sensitive projects. Choosing between the two fibers depends on balancing performance requirements against cost constraints, where polyolefin excels in affordability and aramid fiber delivers durability and specialized properties.

Processing, Manufacturing, and Fabrication Differences

Aramid fibers undergo complex manufacturing involving solution polymerization and dry spinning, resulting in high tensile strength and thermal stability, whereas polyolefin fibers like polypropylene are produced through melt spinning with simpler, cost-effective processes. Aramid fiber fabrication requires controlled conditions due to sensitivity to moisture and UV exposure, while polyolefin fibers offer easier handling and greater chemical resistance during fabrication. Processing aramid fibers demands precision for orientation and crystallinity to optimize performance; polyolefin fibers provide versatility with faster cycle times and lower energy consumption in thermoplastic forming.

Sustainability and Environmental Impact

Aramid fiber offers high strength and durability with recyclability challenges due to its complex polymer structure, leading to limited biodegradability and energy-intensive production processes. Polyolefin fiber, derived from simpler hydrocarbons like polyethylene and polypropylene, demonstrates better recyclability and lower carbon emissions during manufacturing, making it more environmentally sustainable. In sustainability assessments, polyolefin fibers contribute to reduced landfill waste and enhanced circular economy potential compared to aramid fibers.

Choosing Between Aramid and Polyolefin: Key Factors

Choosing between aramid fiber and polyolefin fiber depends on application-specific factors such as strength, thermal resistance, and cost efficiency. Aramid fibers offer exceptional tensile strength and high heat resistance, making them ideal for protective gear and aerospace applications, while polyolefin fibers provide lightweight, chemical resistance, and cost-effective solutions suitable for packaging and textiles. Evaluating the environmental conditions, mechanical demands, and budget constraints will determine the optimal fiber choice for each project.

Aramid Fiber vs Polyolefin Fiber Infographic

materialdif.com

materialdif.com