Regenerated fibers are derived from natural polymers such as cellulose, chemically processed to create fibers like rayon and lyocell, offering biodegradability and breathability. Man-made fibers, often produced from petrochemical materials like polyester and nylon, provide enhanced durability, elasticity, and resistance to environmental factors. Understanding the distinction between regenerated and man-made fibers is essential for selecting textiles based on sustainability, performance, and end-use requirements.

Table of Comparison

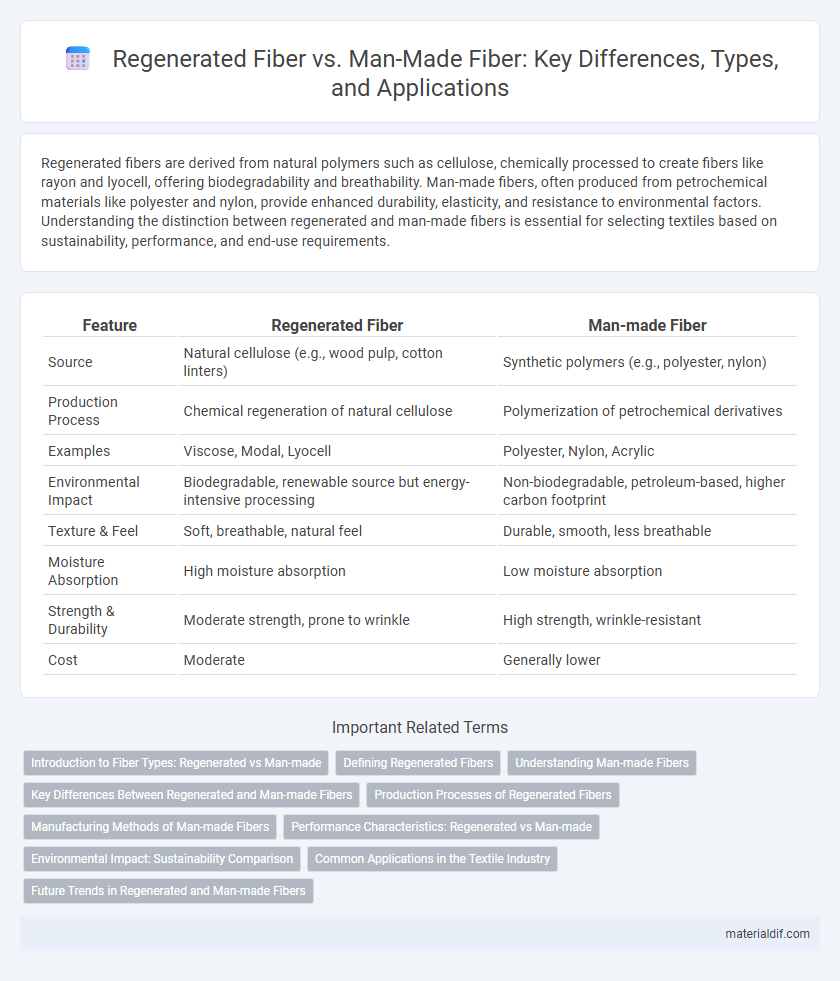

| Feature | Regenerated Fiber | Man-made Fiber |

|---|---|---|

| Source | Natural cellulose (e.g., wood pulp, cotton linters) | Synthetic polymers (e.g., polyester, nylon) |

| Production Process | Chemical regeneration of natural cellulose | Polymerization of petrochemical derivatives |

| Examples | Viscose, Modal, Lyocell | Polyester, Nylon, Acrylic |

| Environmental Impact | Biodegradable, renewable source but energy-intensive processing | Non-biodegradable, petroleum-based, higher carbon footprint |

| Texture & Feel | Soft, breathable, natural feel | Durable, smooth, less breathable |

| Moisture Absorption | High moisture absorption | Low moisture absorption |

| Strength & Durability | Moderate strength, prone to wrinkle | High strength, wrinkle-resistant |

| Cost | Moderate | Generally lower |

Introduction to Fiber Types: Regenerated vs Man-made

Regenerated fibers are derived from natural polymers such as cellulose, chemically processed to form fibers, with viscose and lyocell being prime examples. Man-made fibers, also known as synthetic fibers, are produced entirely from petrochemicals through polymerization, including polyester, nylon, and acrylic. Understanding the differences in raw materials and manufacturing processes is crucial for applications in textiles, as regenerated fibers offer biodegradability while man-made fibers provide enhanced durability and elasticity.

Defining Regenerated Fibers

Regenerated fibers are derived from natural polymers, primarily cellulose extracted from wood pulp or cotton linters, which are chemically processed and spun into fibers. Unlike synthetic man-made fibers produced from petrochemicals, regenerated fibers maintain much of the natural fiber's biodegradable and breathable properties. Common examples include viscose, modal, and lyocell, widely used in textiles for their sustainability and comfort benefits.

Understanding Man-made Fibers

Man-made fibers are synthetic or semi-synthetic materials produced through chemical processes, primarily derived from petrochemicals or cellulose sources. Regenerated fibers, a subset of man-made fibers, are created by chemically transforming natural polymers such as cellulose from wood pulp into filament fibers, exemplified by rayon and lyocell. Understanding the distinction highlights the environmental and functional differences, as man-made fibers offer controlled properties and versatility, while regenerated fibers maintain a degree of biodegradability due to their natural origins.

Key Differences Between Regenerated and Man-made Fibers

Regenerated fibers, derived from natural cellulose sources like wood pulp or cotton linters, undergo chemical processes that reform the fiber structure, exemplified by viscose and lyocell. Man-made fibers, also known as synthetic fibers, are produced entirely from petrochemicals through polymerization, with common examples including polyester, nylon, and acrylic. Key differences lie in their origin, biodegradability, moisture absorption, and texture, where regenerated fibers tend to be more breathable and biodegradable, while man-made fibers offer higher durability and resistance to wrinkles and chemicals.

Production Processes of Regenerated Fibers

Regenerated fibers are produced by chemically processing natural polymers like cellulose from wood pulp, which is dissolved and then extruded through spinnerets to form fibers, distinguishing them from man-made fibers created from synthetic polymers such as nylon or polyester. The viscose process, lyocell process, and cuprammonium process are key methods for producing regenerated cellulose fibers, emphasizing sustainability through the reuse of natural raw materials. These production processes result in fibers with properties closely resembling natural fibers, offering enhanced breathability and biodegradability compared to fully synthetic man-made fibers.

Manufacturing Methods of Man-made Fibers

Man-made fibers are produced through chemical synthesis using raw materials such as petroleum derivatives, involving processes like polymerization and extrusion to form continuous filaments. Manufacturing methods include melt spinning, where polymer granules are melted and extruded through spinnerets, and wet or dry spinning, which dissolve polymers in solvents before fiber formation. These techniques enable precise control over fiber properties such as strength, elasticity, and moisture resistance, distinguishing man-made fibers from regenerated fibers that are derived from natural cellulose sources.

Performance Characteristics: Regenerated vs Man-made

Regenerated fibers, derived from natural polymers like cellulose, exhibit superior moisture absorption and breathability compared to man-made fibers, enhancing comfort in textiles. Man-made fibers, created through chemical synthesis, typically offer greater strength, durability, and resistance to chemicals and UV degradation. Performance characteristics of regenerated fibers prioritize environmental sustainability and skin-friendliness, while man-made fibers excel in engineering applications requiring high tensile strength and dimensional stability.

Environmental Impact: Sustainability Comparison

Regenerated fibers, such as viscose and lyocell, are derived from natural cellulose sources like wood pulp, offering higher biodegradability and lower carbon emissions compared to fully synthetic man-made fibers like polyester and nylon. The production of regenerated fibers typically involves less reliance on fossil fuels but may still use chemical-intensive processes that impact water quality, whereas man-made fibers often depend heavily on petrochemicals, contributing to microplastic pollution and non-biodegradability. Sustainable innovations in regenerated fiber manufacturing, including closed-loop systems and sustainable forestry practices, improve their eco-friendliness relative to the more resource-intensive and pollution-heavy lifecycle of conventional man-made fibers.

Common Applications in the Textile Industry

Regenerated fibers, derived from natural polymers like cellulose, are extensively used in producing soft, breathable textiles such as rayon, viscose, and lyocell, often found in apparel, home furnishings, and medical dressings. Man-made fibers, including nylon, polyester, and acrylic, are synthetic polymers widely utilized for their durability and moisture-wicking properties in activewear, outdoor gear, upholstery, and industrial fabrics. Both fiber types play crucial roles in the textile industry, with regenerated fibers favored for comfort and sustainability, while man-made fibers excel in performance and versatility.

Future Trends in Regenerated and Man-made Fibers

Future trends in regenerated fibers emphasize sustainability through the use of biodegradable materials and innovative recycling technologies that reduce environmental impact. Man-made fibers are increasingly advancing with enhanced functional properties such as moisture-wicking, UV protection, and antimicrobial capabilities driven by nanotechnology integration. Both fiber types are converging towards eco-friendly production methods and circular economy principles, signaling a significant shift in textile manufacturing practices.

Regenerated Fiber vs Man-made Fiber Infographic

materialdif.com

materialdif.com