Combed fiber undergoes a meticulous process that removes short fibers and impurities, resulting in a smoother, stronger, and more uniform yarn ideal for high-quality textiles. Carded fiber, by contrast, is less refined, retaining more short fibers and creating a fluffier, bulkier texture suitable for products requiring softness over durability. Choosing between combed and carded fiber depends on the desired fabric strength, texture, and application in the final product.

Table of Comparison

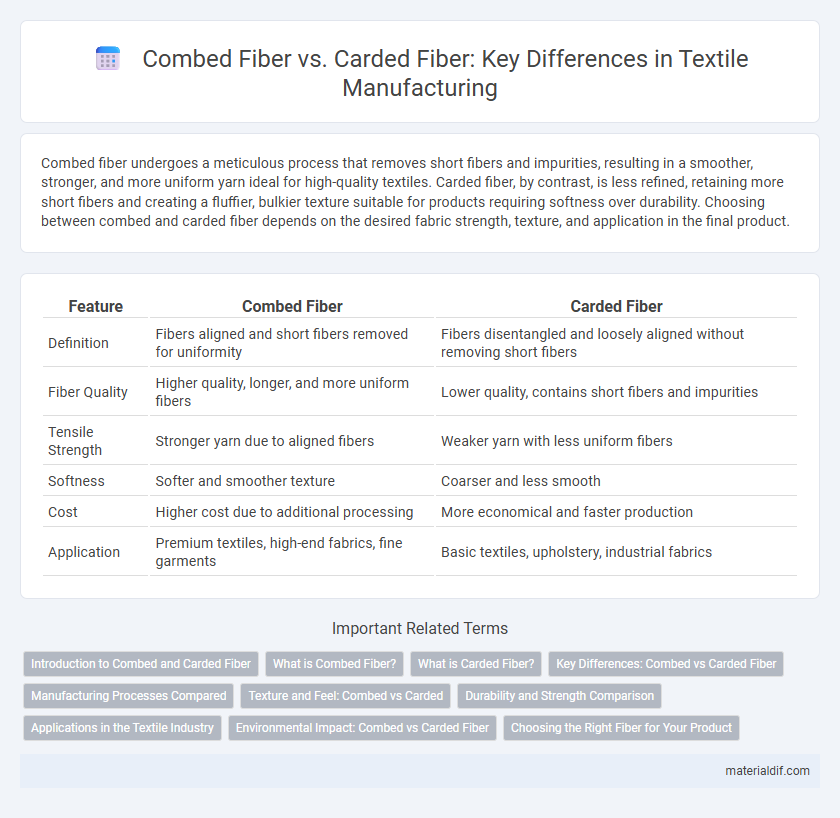

| Feature | Combed Fiber | Carded Fiber |

|---|---|---|

| Definition | Fibers aligned and short fibers removed for uniformity | Fibers disentangled and loosely aligned without removing short fibers |

| Fiber Quality | Higher quality, longer, and more uniform fibers | Lower quality, contains short fibers and impurities |

| Tensile Strength | Stronger yarn due to aligned fibers | Weaker yarn with less uniform fibers |

| Softness | Softer and smoother texture | Coarser and less smooth |

| Cost | Higher cost due to additional processing | More economical and faster production |

| Application | Premium textiles, high-end fabrics, fine garments | Basic textiles, upholstery, industrial fabrics |

Introduction to Combed and Carded Fiber

Combed fiber undergoes a meticulous process that removes short fibers and impurities, resulting in a smoother, stronger, and more uniform yarn. Carded fiber experiences an initial brushing to untangle and clean fibers, producing a bulkier and softer texture ideal for warmth and comfort. These fundamental differences in fiber preparation directly impact the quality and applications of the final textile products.

What is Combed Fiber?

Combed fiber is a high-quality textile fiber that undergoes a meticulous combing process to remove short fibers and impurities, resulting in longer, more aligned strands ideal for producing smoother, stronger yarns. This technique enhances fiber uniformity and luster, making it preferred for premium fabrics such as fine cotton and wool blends. Combed fiber's improved strength and softness distinguish it from carded fiber, which retains shorter fibers and produces coarser, less uniform yarns.

What is Carded Fiber?

Carded fiber consists of raw fibers that have been processed through a carding machine to separate and align them into a loose, fluffy web, making it ideal for spinning coarse yarns and textile manufacturing. This method removes impurities and short fibers, producing a thicker, less uniform strand compared to combed fiber. Carded fiber is widely used in products requiring bulk and insulation, such as upholstery, blankets, and heavy-duty garments.

Key Differences: Combed vs Carded Fiber

Combed fiber undergoes an extra process that removes shorter fibers and aligns the remaining fibers parallel, resulting in a smoother, stronger, and finer yarn compared to carded fiber, which retains more irregular and shorter fibers, producing a bulkier and rougher fabric. Carded fiber is more cost-effective and offers greater insulation due to its looser fiber structure, while combed fiber provides superior durability and a luxurious finish ideal for high-quality textiles. The choice between combed and carded fiber directly influences the texture, strength, and price of the final textile product.

Manufacturing Processes Compared

Combed fiber undergoes a meticulous manufacturing process that aligns fibers parallel by removing short fibers and impurities, resulting in smoother, finer yarns ideal for high-quality textiles. Carded fiber manufacturing involves loosely disentangling, cleaning, and intermixing fibers to produce a thicker, bulkier yarn suitable for durable and inexpensive fabrics. The differences in combing and carding techniques directly impact fiber strength, uniformity, and fabric texture, making combed fibers preferable for premium apparel and carded fibers suited for casual wear or insulation materials.

Texture and Feel: Combed vs Carded

Combed fiber features a smoother, finer texture due to the removal of short fibers and impurities, resulting in a softer and more luxurious feel ideal for high-quality textiles. Carded fiber retains more short fibers and irregularities, producing a coarser texture with a bulkier and less refined hand that is typically used for durable, everyday fabrics. The combing process enhances fiber alignment, delivering improved softness and strength compared to the rougher, airier structure of carded fibers.

Durability and Strength Comparison

Combed fiber undergoes a more thorough refining process that removes short fibers and impurities, resulting in a stronger, more durable yarn compared to carded fiber. Carded fiber contains a mix of long and short fibers, which makes it less uniform and prone to pilling and wear over time. The enhanced alignment and length of fibers in combed yarn contribute to superior tensile strength and longevity in textile applications.

Applications in the Textile Industry

Combed fiber, known for its smoothness and strength due to the removal of short fibers and impurities, is ideal for high-quality textiles such as fine shirts, luxury fabrics, and premium knitwear. Carded fiber, which retains more short fibers and shows a fuzzier texture, is widely used in products requiring bulk and warmth like sweaters, blankets, and upholstery. The choice between combed and carded fibers significantly impacts fabric durability, softness, and overall quality in the textile industry.

Environmental Impact: Combed vs Carded Fiber

Combed fiber production generates higher-quality yarn by removing shorter fibers and impurities, resulting in a more refined textile with less waste during manufacturing. Carded fiber processing, while less resource-intensive, produces a bulkier yarn with more irregularities, often leading to increased material waste and energy consumption in downstream manufacturing. Environmentally, combed fibers support sustainability by extending product lifespan and reducing the need for frequent replacements, whereas carded fibers may contribute to higher overall environmental impact due to lower durability and increased resource use.

Choosing the Right Fiber for Your Product

Combed fiber undergoes an extra process that removes short fibers and impurities, resulting in a smoother, stronger, and more uniform yarn ideal for high-quality textiles and fine garments. Carded fiber retains more short fibers and debris, producing a bulkier, less consistent yarn suitable for casual wear and products requiring more texture and warmth. Selecting combed or carded fiber depends on the desired fabric durability, softness, and appearance for your specific product needs.

Combed Fiber vs Carded Fiber Infographic

materialdif.com

materialdif.com