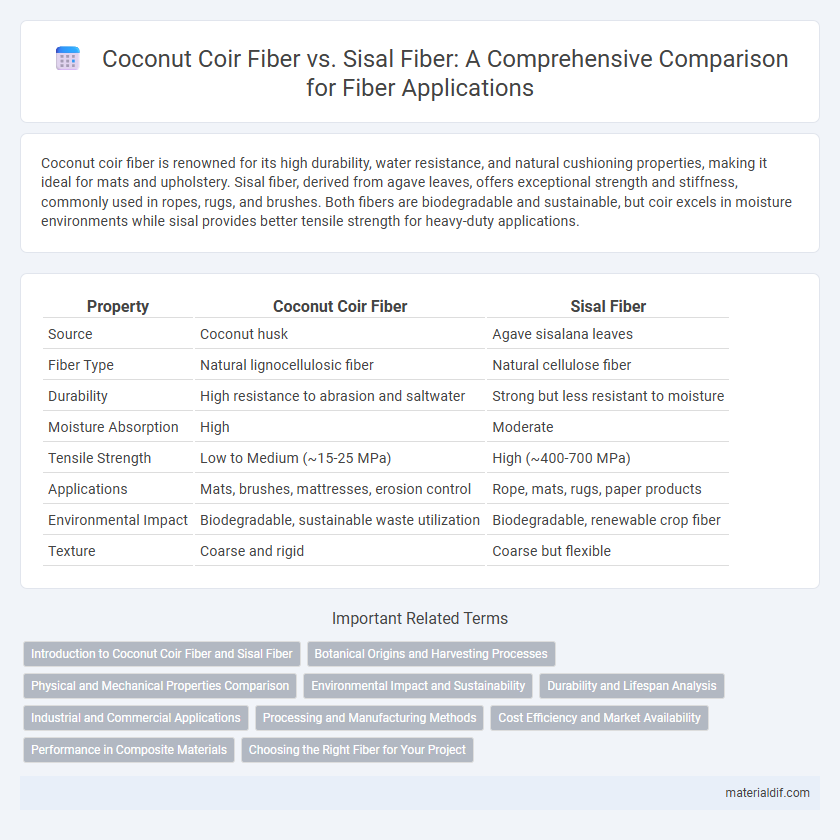

Coconut coir fiber is renowned for its high durability, water resistance, and natural cushioning properties, making it ideal for mats and upholstery. Sisal fiber, derived from agave leaves, offers exceptional strength and stiffness, commonly used in ropes, rugs, and brushes. Both fibers are biodegradable and sustainable, but coir excels in moisture environments while sisal provides better tensile strength for heavy-duty applications.

Table of Comparison

| Property | Coconut Coir Fiber | Sisal Fiber |

|---|---|---|

| Source | Coconut husk | Agave sisalana leaves |

| Fiber Type | Natural lignocellulosic fiber | Natural cellulose fiber |

| Durability | High resistance to abrasion and saltwater | Strong but less resistant to moisture |

| Moisture Absorption | High | Moderate |

| Tensile Strength | Low to Medium (~15-25 MPa) | High (~400-700 MPa) |

| Applications | Mats, brushes, mattresses, erosion control | Rope, mats, rugs, paper products |

| Environmental Impact | Biodegradable, sustainable waste utilization | Biodegradable, renewable crop fiber |

| Texture | Coarse and rigid | Coarse but flexible |

Introduction to Coconut Coir Fiber and Sisal Fiber

Coconut coir fiber, derived from the outer husk of coconuts, is a natural, durable, and water-resistant fiber widely used in mats, mattresses, and brushes. Sisal fiber, obtained from the leaves of the Agave sisalana plant, is known for its strength, flexibility, and biodegradability, making it ideal for ropes, rugs, and upholstery. Both fibers are popular for eco-friendly applications, with coconut coir offering superior moisture resistance and sisal providing enhanced tensile strength.

Botanical Origins and Harvesting Processes

Coconut coir fiber is derived from the outer husk of the Cocos nucifera palm, harvested by soaking and retting the husks to separate the fibrous material. Sisal fiber originates from the leaves of the Agave sisalana plant, extracted through a decortication process that scrapes away the pulp to obtain long, strong fibers. The botanical distinction influences fiber texture and durability, while harvesting methods impact fiber quality and environmental sustainability.

Physical and Mechanical Properties Comparison

Coconut coir fiber exhibits higher tensile strength and greater abrasion resistance compared to sisal fiber, making it more durable for heavy-duty applications. Sisal fiber, however, demonstrates superior stiffness and a higher modulus of elasticity, resulting in better rigidity and structural stability. Both fibers differ in moisture absorption rates, with coir having a higher capacity, which influences their performance in varying environmental conditions.

Environmental Impact and Sustainability

Coconut coir fiber is highly sustainable, sourced as a byproduct of coconut farming, and requires minimal chemical processing, resulting in low environmental impact. Sisal fiber, derived from the agave plant, also boasts biodegradability and renewable qualities but involves more intensive water usage and land resources during cultivation. Both fibers support biodegradable production, yet coconut coir's use of agricultural waste positions it as a more eco-friendly option in sustainable fiber industries.

Durability and Lifespan Analysis

Coconut coir fiber exhibits superior durability due to its high lignin content, making it resistant to saltwater and microbial degradation, which extends its lifespan to over 10 years in harsh environments. Sisal fiber, although strong and flexible, has lower lignin levels and is more susceptible to UV damage and rot, typically lasting around 3 to 5 years when exposed to outdoor conditions. Both fibers serve well in different applications, but coconut coir's resilience ensures greater longevity in demanding settings.

Industrial and Commercial Applications

Coconut coir fiber offers superior water resistance and durability, making it ideal for erosion control mats, upholstery padding, and automotive composites. Sisal fiber provides excellent tensile strength and rigidity, suited for rope manufacturing, geotextiles, and brush bristles. Both fibers serve eco-friendly industrial and commercial applications, yet coir's high lignin content enhances biodegradability while sisal's fiber stiffness supports heavy-duty use.

Processing and Manufacturing Methods

Coconut coir fiber undergoes a retting process where mature coconut husks are soaked in water to loosen the fibers, followed by mechanical extraction and drying for durability. Sisal fiber is extracted from the Agave sisalana leaves through decortication, where the leaf pulp is crushed and washed to isolate strong, stiff fibers, then dried and brushed for uniformity. Manufacturing of coir typically involves traditional manual techniques in coastal regions, whereas sisal production has become more mechanized, enhancing fiber quality and consistency.

Cost Efficiency and Market Availability

Coconut coir fiber is generally more cost-efficient than sisal fiber due to its widespread availability as a byproduct of coconut processing, which reduces raw material expenses. Sisal fiber, while durable and strong, tends to have higher market prices because of its specialized cultivation and limited geographic production areas. The global market for coconut coir fiber is larger and more accessible, offering better supply stability compared to the relatively niche and fluctuating sisal fiber market.

Performance in Composite Materials

Coconut coir fiber exhibits excellent impact resistance and water absorption properties, making it highly suitable for composite materials exposed to moisture. Sisal fiber offers superior tensile strength and stiffness, enhancing structural integrity in composites requiring durability under mechanical stress. Both fibers provide eco-friendly reinforcement options, with selection depending on specific composite performance requirements such as flexibility or rigidity.

Choosing the Right Fiber for Your Project

Coconut coir fiber offers excellent water resistance and durability, making it ideal for outdoor mats, upholstery, and erosion control. Sisal fiber, known for its strength and stiffness, is better suited for rope, rugs, and heavy-duty brush bristles. Consider the fiber's tensile strength, moisture absorption, and environmental impact when choosing between coconut coir and sisal for your specific project needs.

Coconut Coir Fiber vs Sisal Fiber Infographic

materialdif.com

materialdif.com